Continuous and automatic steel wire rod pay-off rack

A technology for pay-off racks and wire rods, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc. It can solve the problems of easy-to-disrupt pay-off lines, abnormal wear on the surface of wire rods, and good wire rod stiffness and high stress. , to avoid equipment damage, improve product quality, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

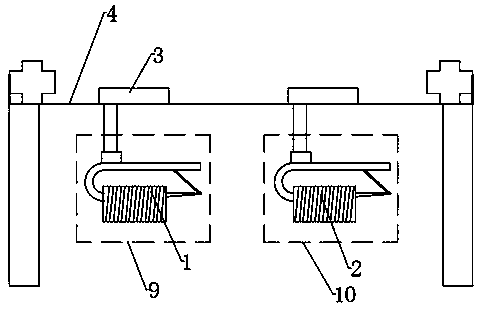

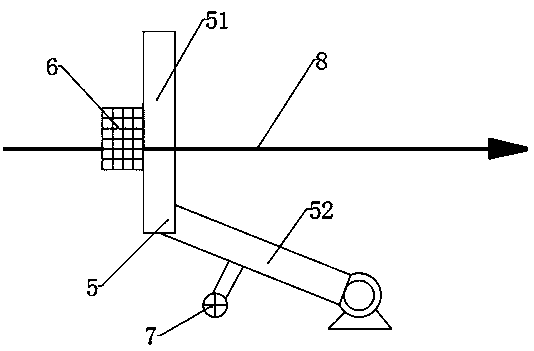

[0020] Such as Figure 1-Figure 3 As shown, a continuous automatic wire rod pay-off rack includes two parallel tracks 4, a bridge mounted on the parallel tracks 4 and perpendicular to the tracks, a pay-off area 10 and a preparation area 9, a release area 10 and a preparation area 9 are equipped with electromagnetic sucker cranes 3 that move horizontally along the bridge frame. The first pay-off car 2 is provided in the pay-off area 10, and the first pay-off car 2 moves along the track 4 through the electromagnetic sucker crane 3. The preparation area 9 is equipped with a first The second pay-off car 1, and the second pay-off car 1 moves along the track 4 through the electromagnetic sucker crane 3, and the electromagnetic sucker crane 3 is controlled by a PLC controller;

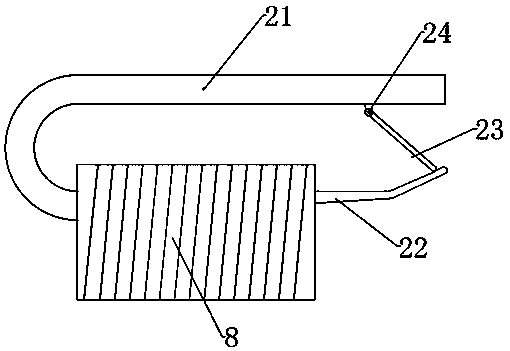

[0021] The first and the second pay-off car are all provided with L-shaped disorderly wire protection frame 23, and the disorderly wire protection frame 23 is provided with a disorderly wire protection sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com