Construction method of cast-in-place box girder with variable curvature based on adjustable formwork

A box girder construction and shaping technology, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems affecting the spatial alignment of bridge structures and the quality of pouring construction, the difficulty of ensuring the quality of concrete maintenance, and the poor production effect of steel cages, etc. problems, to achieve the effect of fast moisturizing and maintenance, convenient assembly, and reducing the requirements for personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Construction technical requirements for construction platform layout, on-site welding construction technical requirements, concrete mix ratio design and pouring construction technical requirements, formwork design and construction technical requirements, built-in sliding water spray device production and water spray construction technical requirements, etc., are not included in this embodiment. The details will be described again, and the embodiments of the methods involved in the present invention will be focused on.

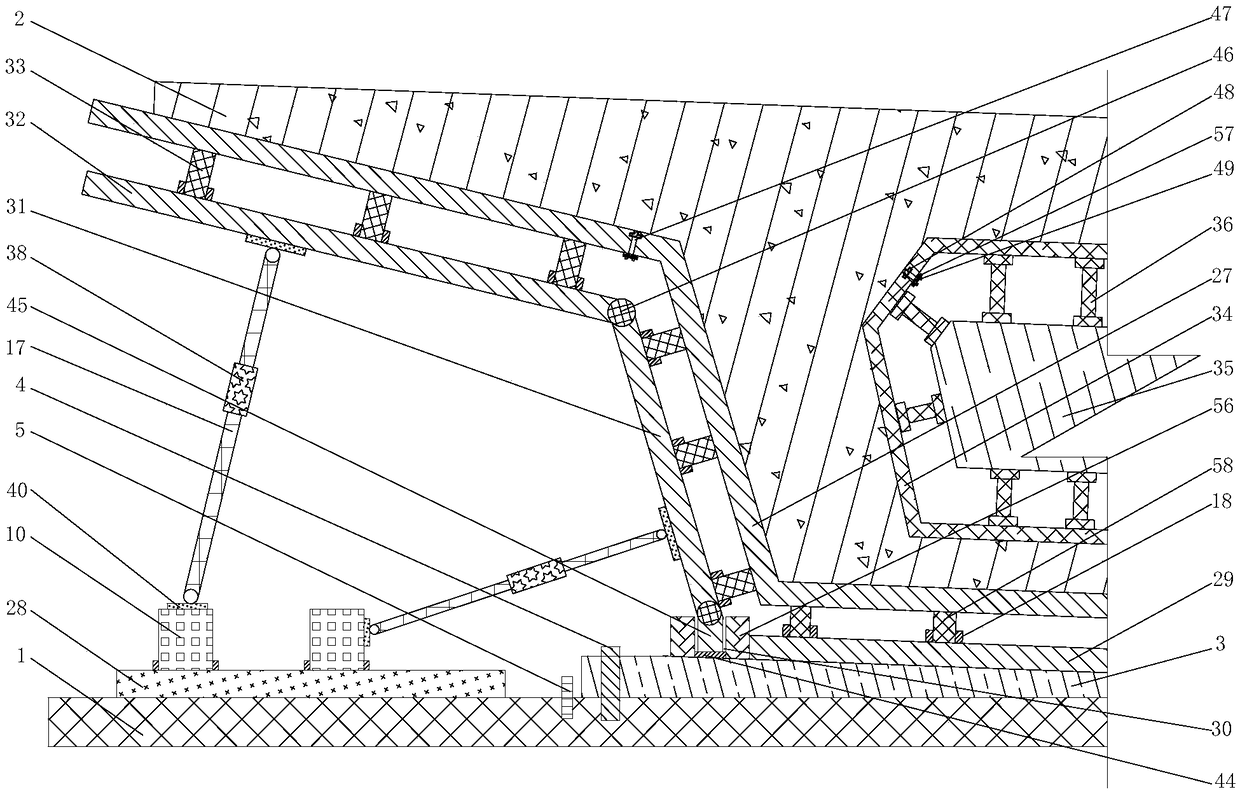

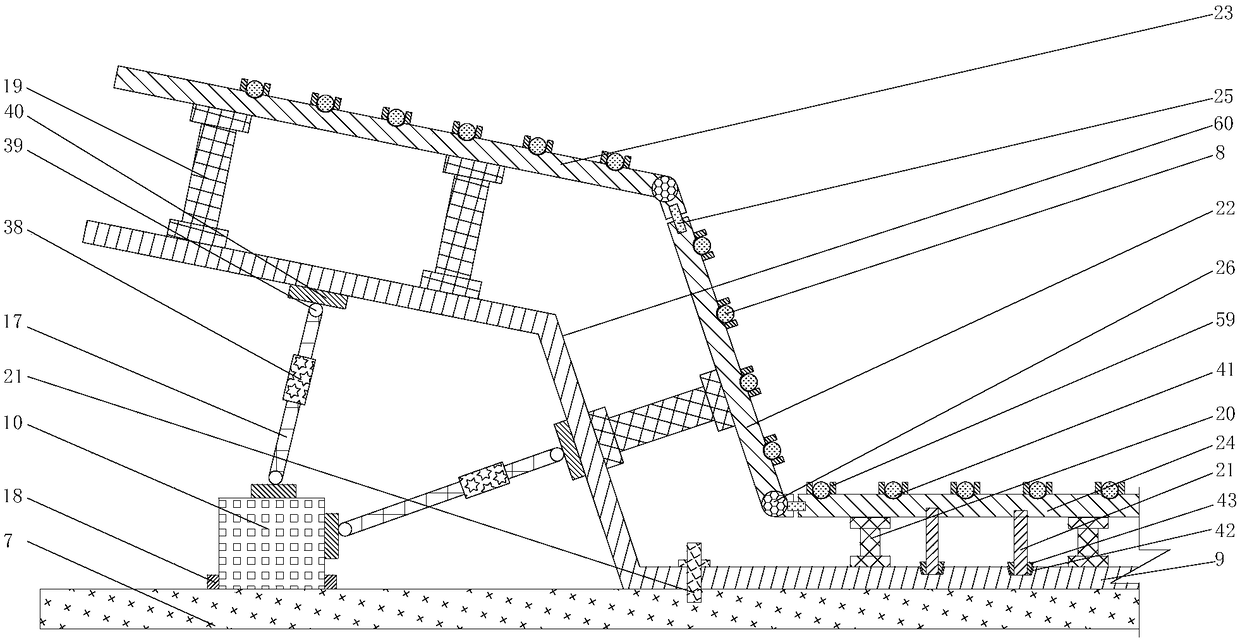

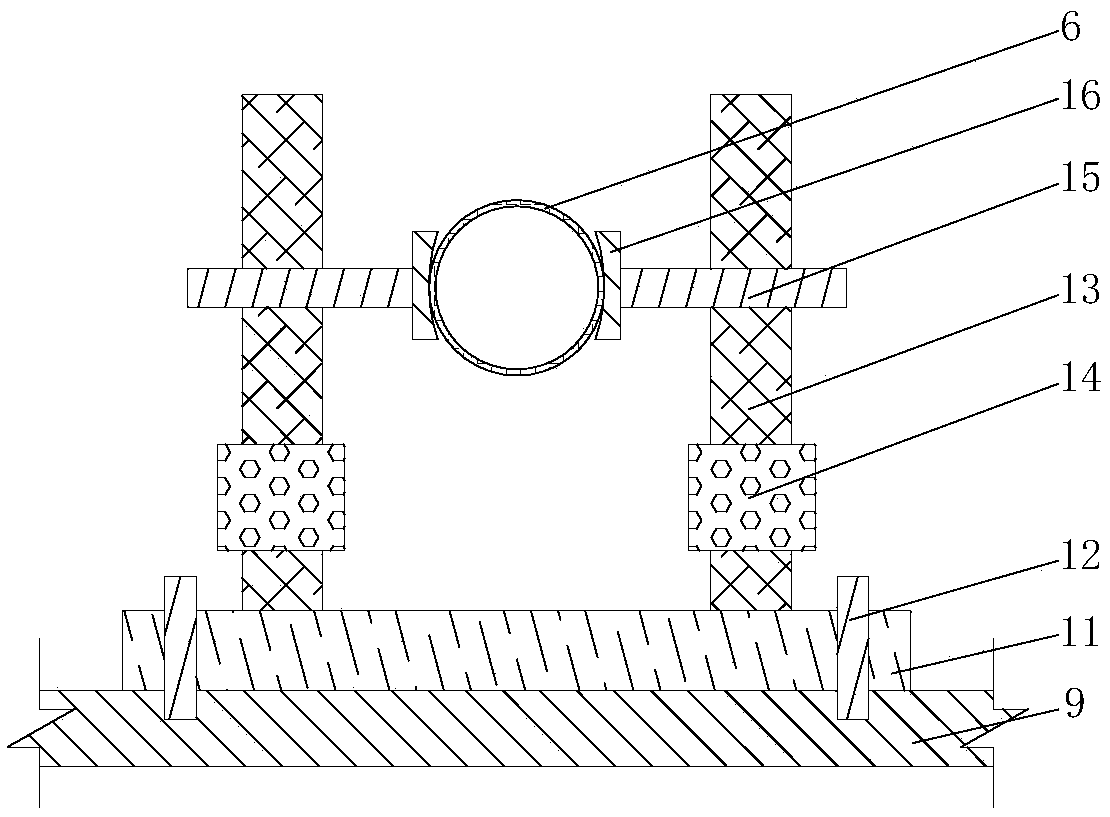

[0035] figure 1 It is a schematic diagram of the pouring structure of the cast-in-place box girder based on the variable curvature of the adjustable formwork of the present invention; figure 2 It is a schematic cross-sectional view of the steel bar positioning tire frame structure of the present invention; image 3 It is a schematic cross-sectional view of the pre-embedded pipe fitting positioning structure of the present invention; Figure 4 It is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com