Auxiliary tooling for construction of indoor distribution box and construction method thereof

A technology for indoor power distribution and auxiliary tooling, which is applied in the installation of cables, cable installation devices, electrical components, etc., and can solve the problems of limited operation space for the connection between distribution boxes and conduits, inconvenient installation and operation, and poor levelness. , to achieve the effect of convenient and fast adjustment and fixing process, neat and smooth arrangement, and increased adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

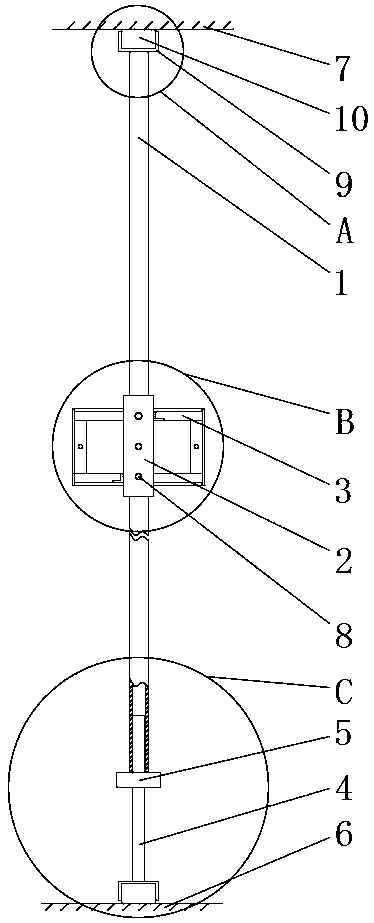

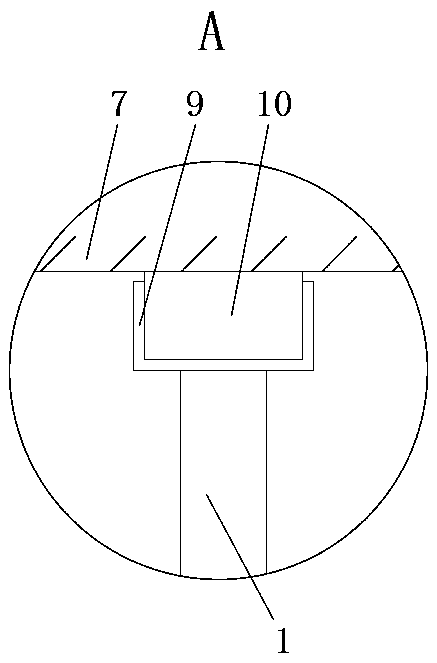

[0035] Such as Figures 1 to 4 As shown in , 6, the auxiliary tooling for indoor distribution box construction includes vertical steel pipe 1, adjusting sleeve 2, jacking mechanism and installation frame 3, and the jacking mechanism includes threaded rod 4 and adjusting seat with internal thread 5. The adjusting seat 5 is threadedly connected with the threaded rod 4, and the adjusting seat 5 has two adjusting ears 11;

[0036] The threaded rod 4 is inserted from the bottom of the steel pipe 1, the top surface of the adjustment seat 5 contacts and supports the bottom of the steel pipe 1, the ground foundation 6 forms a support for the bottom of the threaded rod 4, the top of the steel pipe 1 is used to tighten the indoor roof 7, and the steel pipe 1. It is tightened between the indoor ground foundation 6 and the indoor top 7 through the jacking mechanism, and the vertical position of the steel pipe 1 can be adjusted through the adjustment seat 5. During the vertical adjustment ...

Embodiment 2

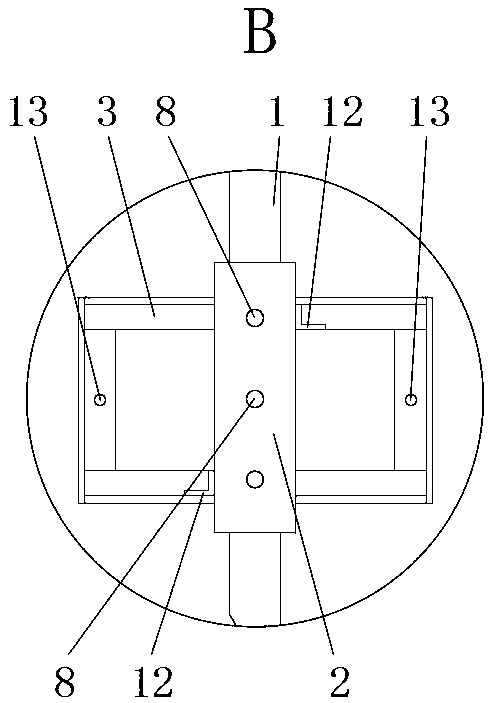

[0040] Such as image 3 with 5 As shown, on the basis of Embodiment 1, the installation frame 3 is composed of four angle steels, and the four angle steels are welded to form a rectangular frame. The horizontal angle steels 12 are located on the left and right sides of the adjusting sleeve 2 respectively, and the two horizontal angle steels 12 are respectively welded and fixed to the upper angle steel and the lower angle steel of the rectangular frame.

Embodiment 3

[0042] Such as image 3 As shown, on the basis of Embodiment 2, a through hole 13 is opened on the angle steel of the installation frame 3, and the position of the through hole 13 matches the position of the installation hole (not shown in the figure) on the distribution box. The quantity and position are set according to the number and specific positions of the installation holes on the distribution box, and the fixed connection between the distribution box and the installation frame 3 is realized by passing through the through holes 13 and the installation holes with screws (not shown in the figure).

[0043] In the construction method of the above-mentioned auxiliary tooling for the construction of the indoor distribution box, the distribution box is fixedly installed on the installation frame 3, and then the projection position of the distribution box is determined on the ground foundation 6 according to the specific installation position of the distribution box. Move the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com