Self-propelled multifunctional concrete spreader

A multi-functional, distributing machine technology, applied in cranes, construction materials processing, construction, etc., can solve the problems of no supplementary effect, lack of on-site use experience, and inability to fill gaps, etc., to achieve compact structure design and compact structure , The effect of flexible lifting methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the purpose, technical features and technical effects of the technical solution of the present invention more clear, the exemplary solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings of specific embodiments of the present invention.

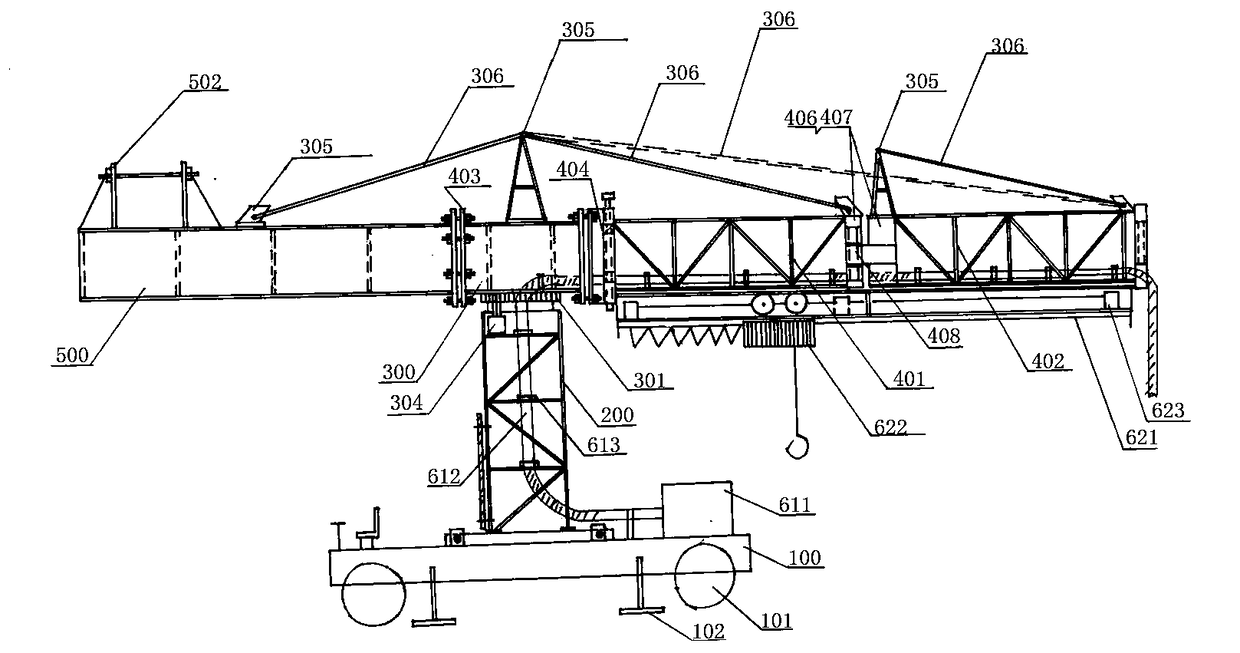

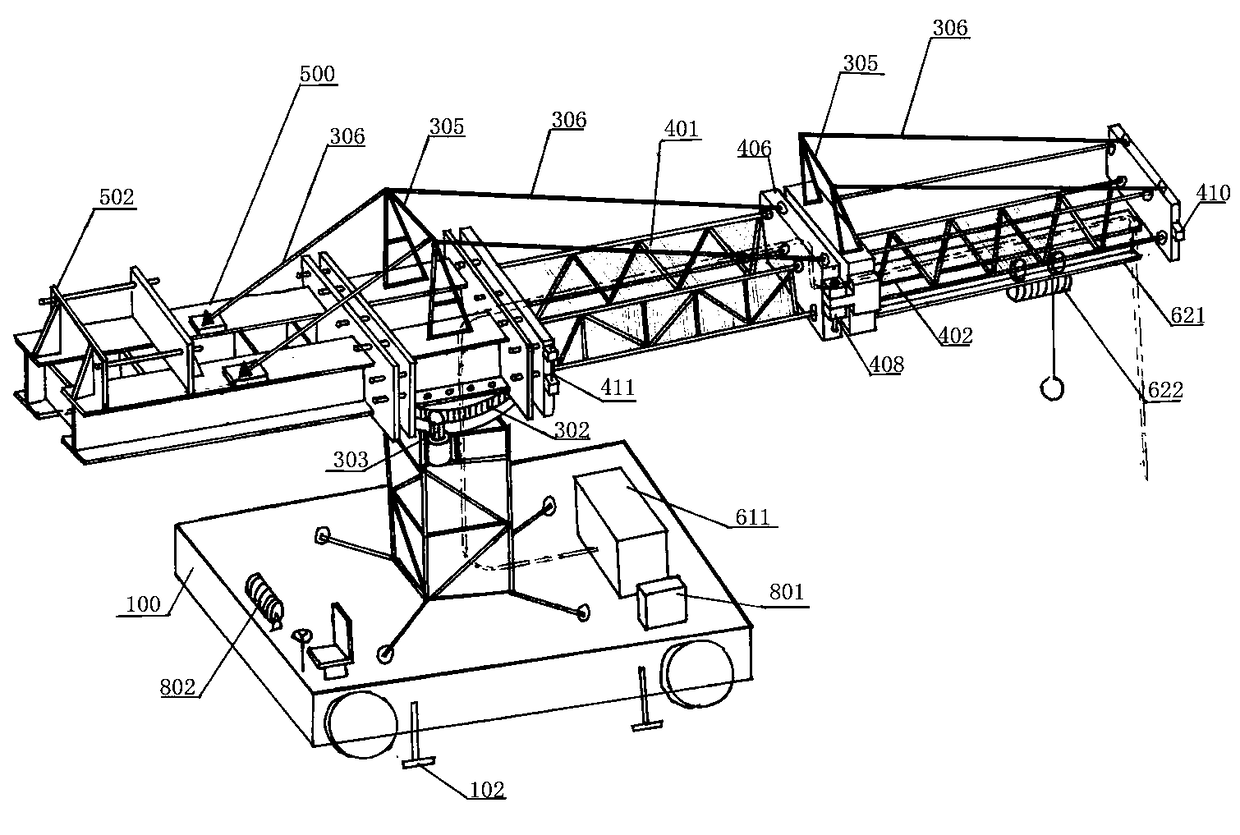

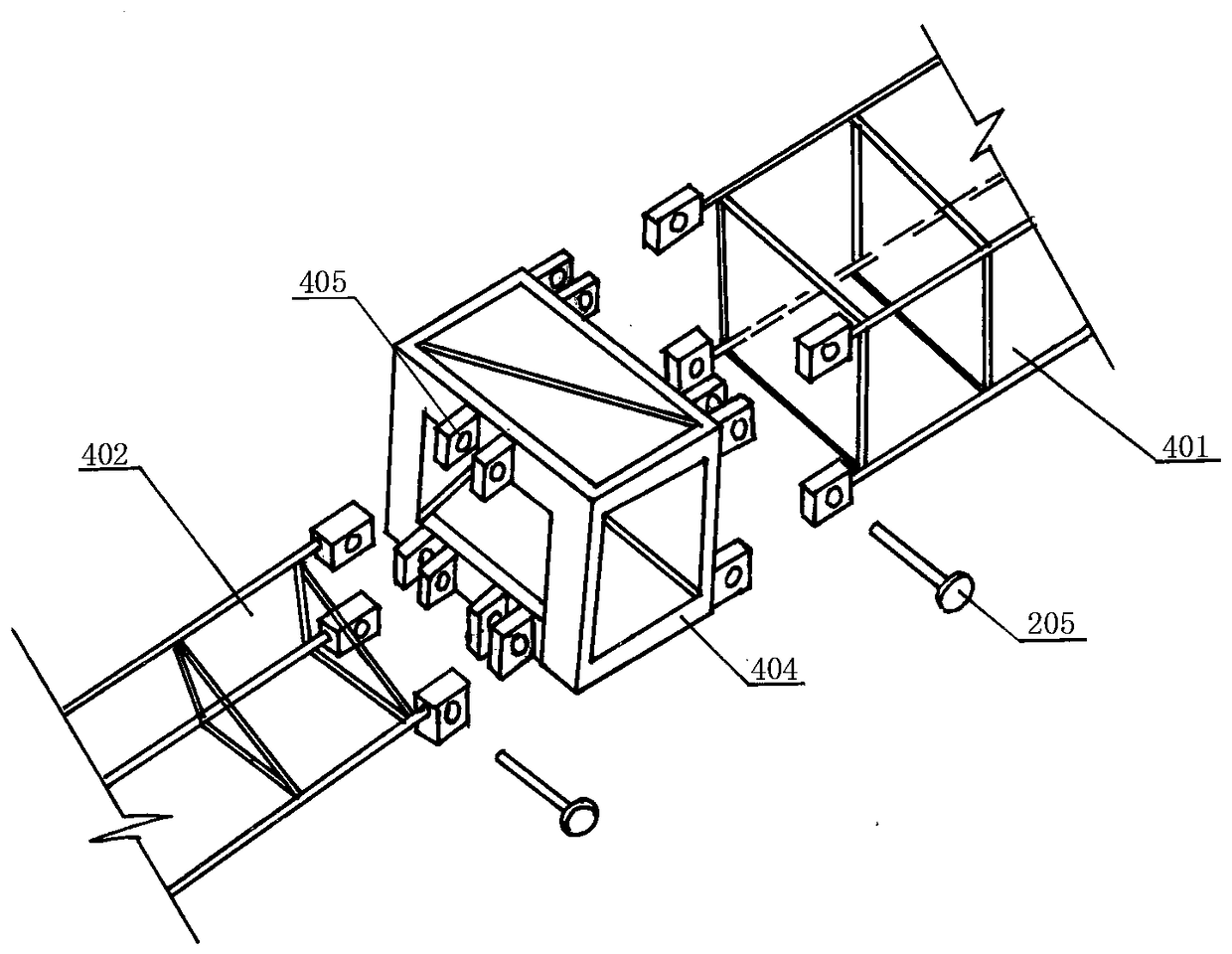

[0048] Referring to the accompanying drawings, the present application discloses a self-propelled multifunctional distribution machine, including a bracket 200, a support arm 300, and a main arm 400 and a balance arm 500 arranged on both sides corresponding to the support arm 300. The support arm 300 passes through the rotary assembly The rotation is arranged on the top of the support 200, and the support arm 300 is driven to rotate relative to the support 200 through the rotation drive assembly; construction components are arranged on the main arm 400.

[0049] Wherein the rotary assembly in this embodiment includes two correspondingly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com