S-shape throwing and withdrawing control method of hydroelectric unit servomotor locking device

A technology of hydroelectric unit and locking device, applied in safety devices, hydroelectric power generation, machines/engines, etc., can solve the problems of overtime of single-step process of starting and stopping, failure of automatic starting and stopping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

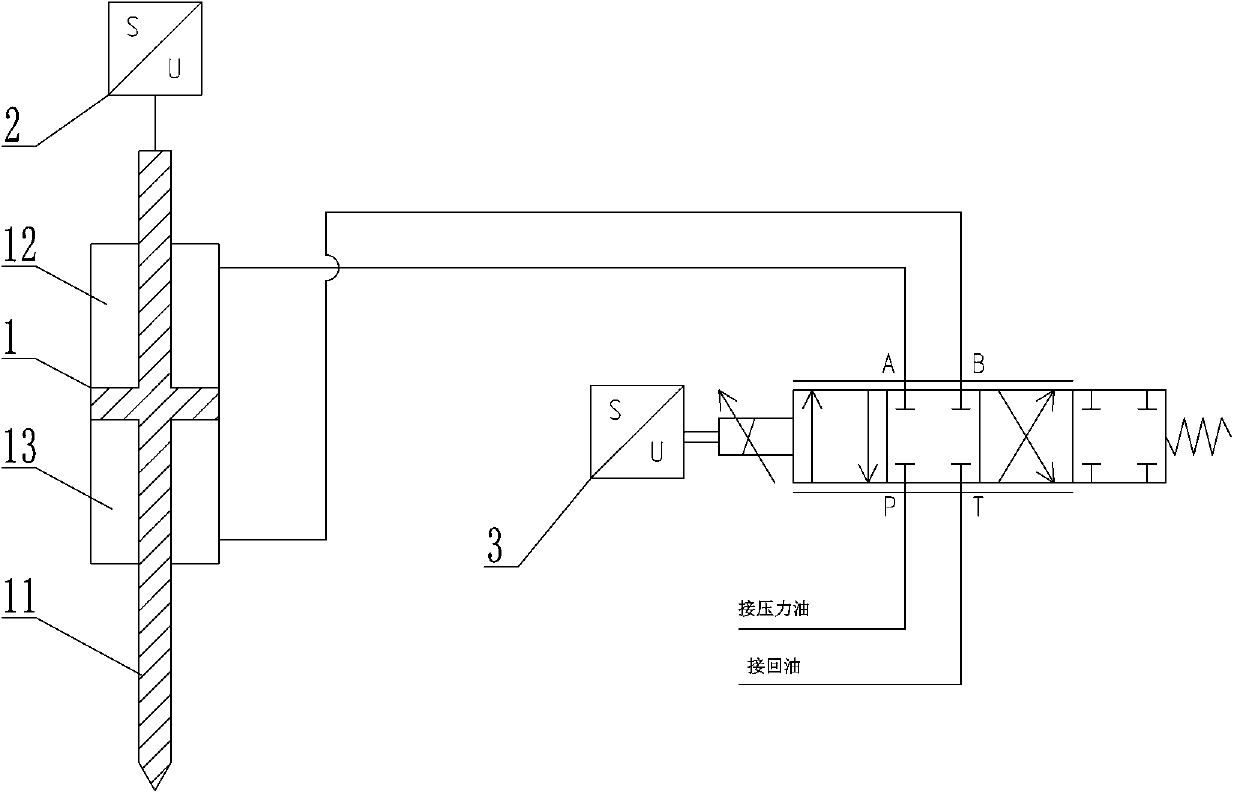

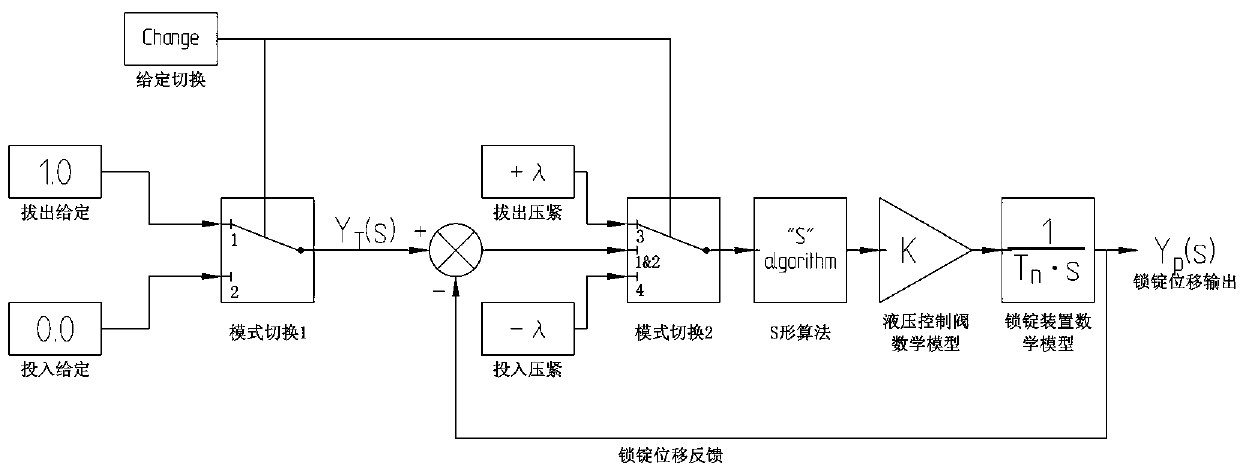

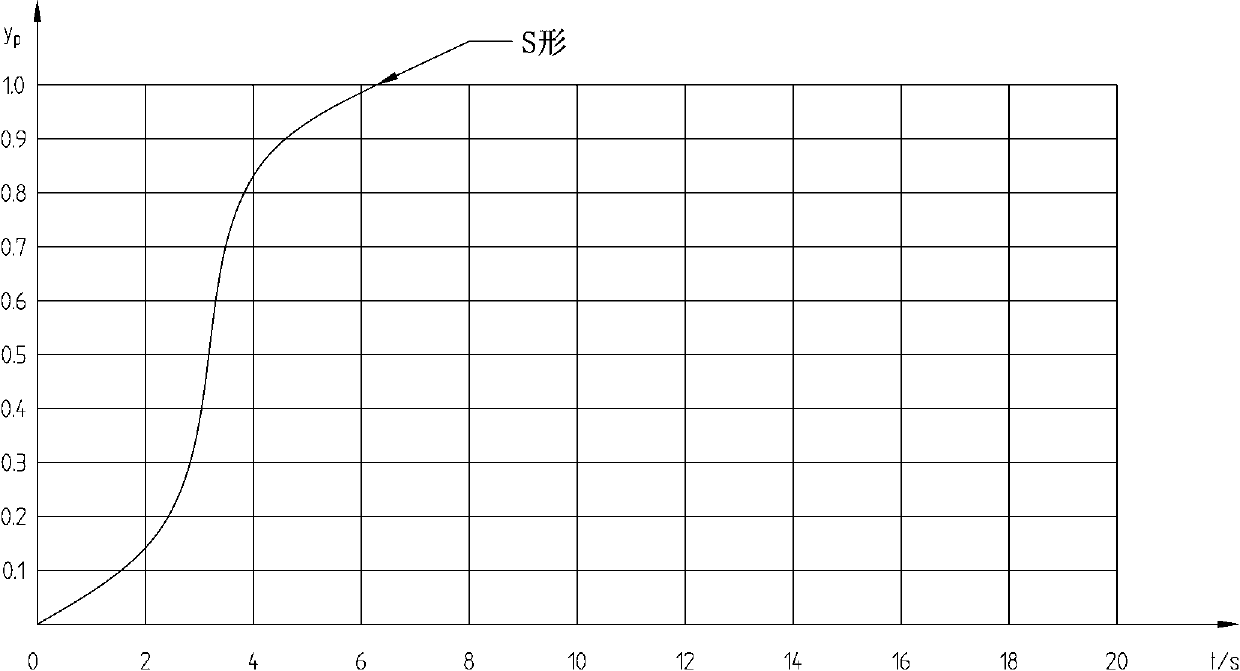

[0024] like Figure 1~Figure 6 Among them, an S-shaped throwing and withdrawing control method of a hydroelectric unit servomotor locking device, which includes a locking servomotor 1, a displacement sensor 2 located at the rear of a locking lever 11, and a hydraulic control valve connected to the input chamber 12 and the withdrawal chamber 13 respectively 3. When the locking rod 11 of the locking servomotor 1 is cast and withdrawn, the starting position moves slowly and accelerates, the middle position moves quickly, and the end position moves slowly and decelerates. The curve of the displacement of the locking rod 11 versus time is "S" shape. Realize that the spindle locking device has good cushioning performance whether it is at the starting position or the end position of the throwing and retreating control, and also takes into account the rapidity of throwing and retreating control, and the position of the spindle locking device will not be changed by mistake when the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com