Pneumatic butterfly valve

A pneumatic butterfly valve and valve body technology, applied in the field of industrial valve actuators and pneumatic butterfly valves, can solve the problems of wasting energy, lax valve closing, affecting energy saving and environmental protection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

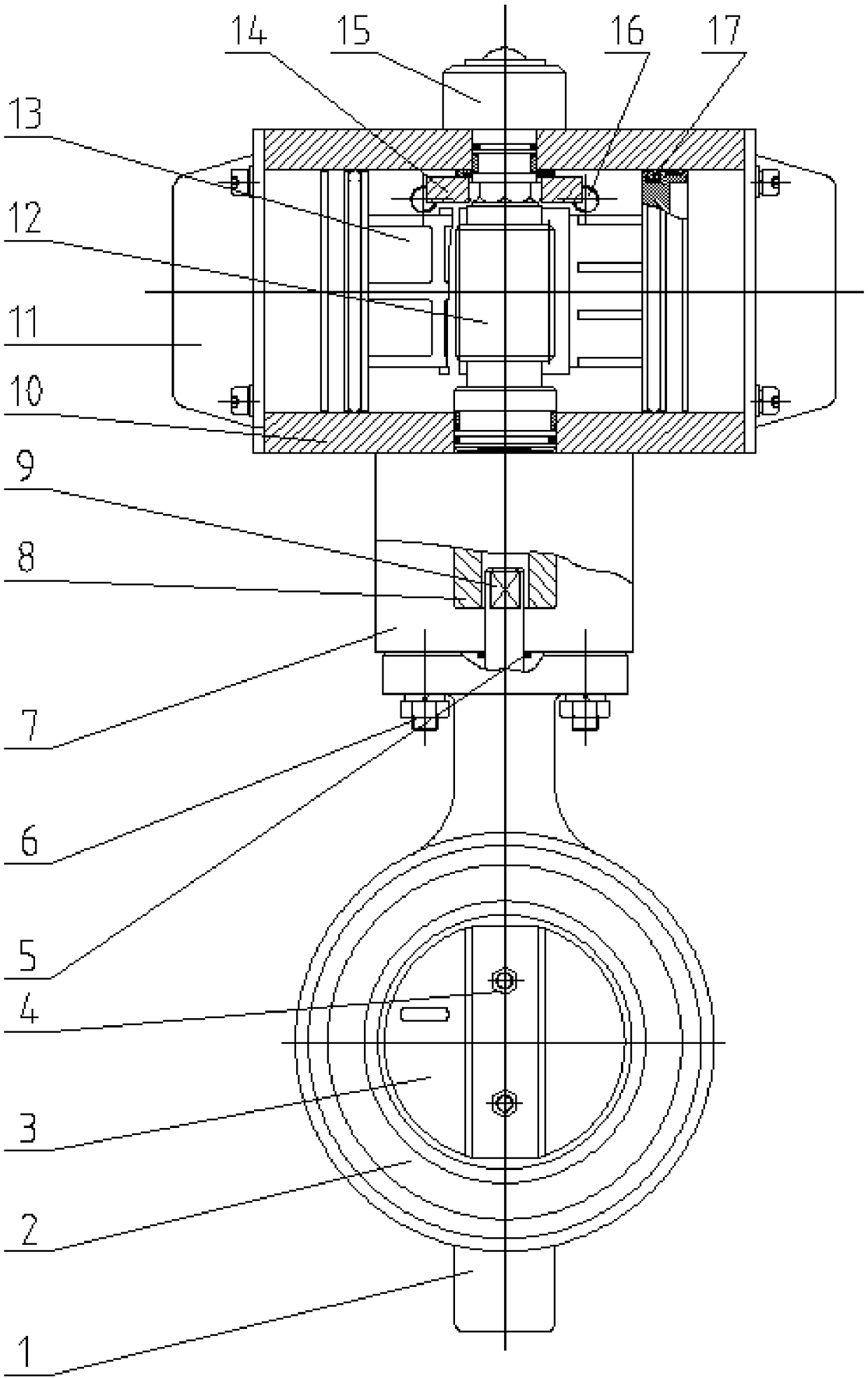

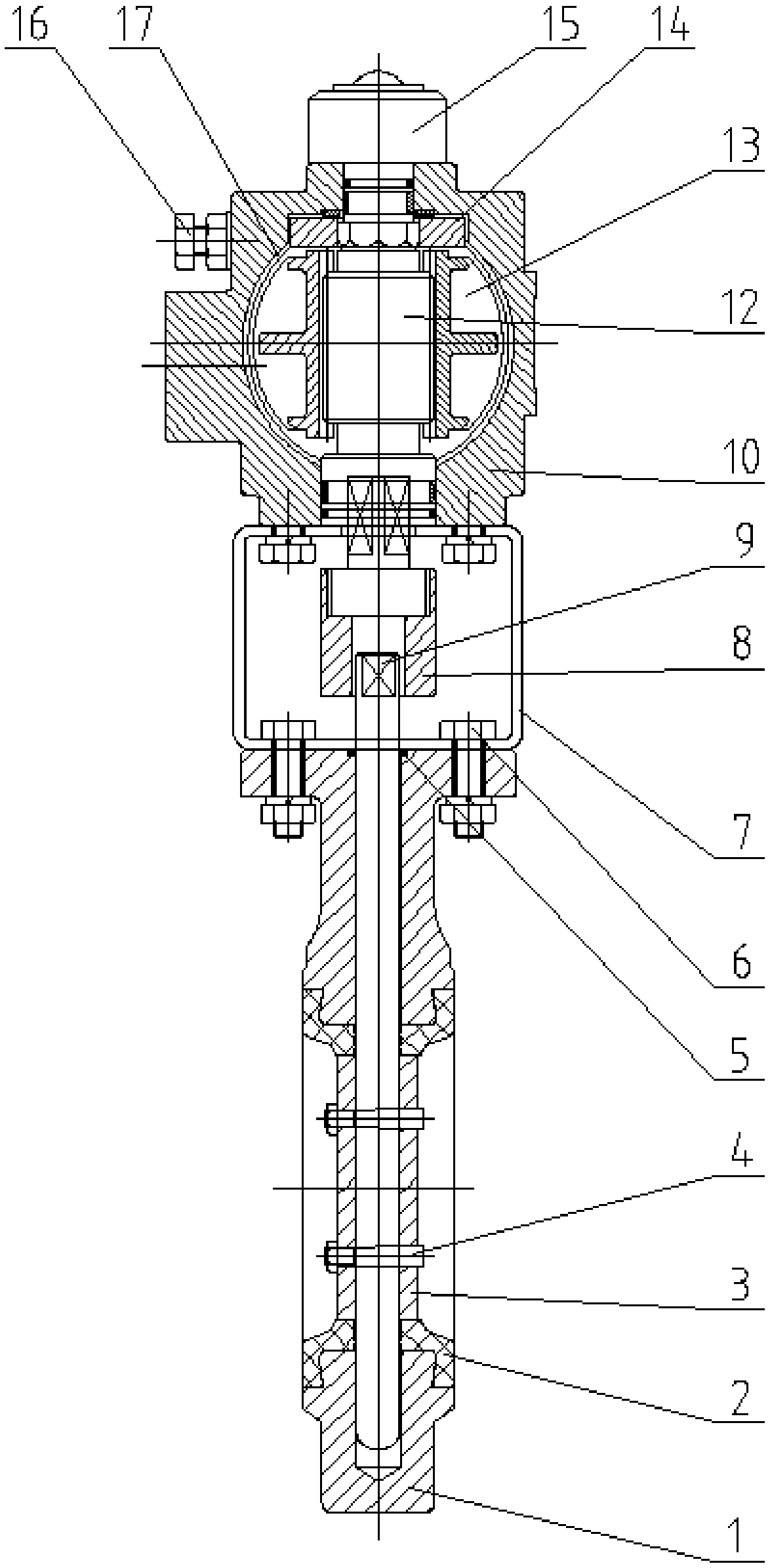

[0012] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0013] The invention is mainly composed of rotary valve sealing parts, valve body parts, cylinder driving actuators and other parts. The rotary valve is driven by the cylinder to drive the actuator to rotate and open and close, so as to open the fluid and block the flow of the fluid.

[0014] to combine figure 1 and figure 2 , the present invention is mainly composed of valve body 1, sealing ring 2, valve 3, valve stem 9, bracket 7, cylinder actuator and the like. The cylinder actuator is mainly composed of a cylinder block 10, an end cover 11, a rack piston 13, a gear output shaft 12, an indicator 15, an adjusting screw 16, a piston sealing ring 17, and the like.

[0015] The valve 3 is installed on the valve stem 9 through the positioning pin 4, and the two ends of the valve stem 9 are placed in the positioning shaft hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com