A kind of optical fiber lead-out method for photonic chip

A technology of photonic chips and optical fibers, applied in the field of optical fiber devices, to achieve the effect of active connection, suitable for mass production, and improve the efficiency of light extraction and coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

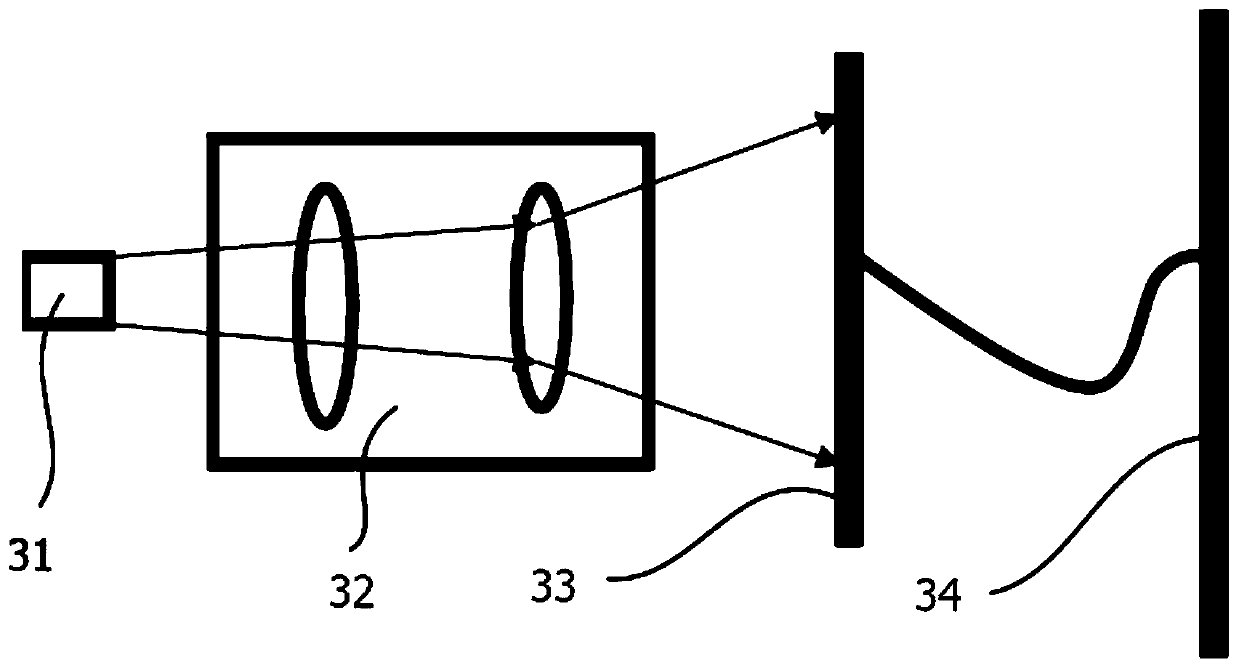

[0040] Such as image 3 As shown, a camera display system is provided, including: an optical magnification system 32, a camera target surface 33, an image processing system and a display 34;

[0041] Measure the position of the camera target surface 33 in advance, and mark a straight line parallel to the camera target surface 33 on the six-dimensional adjustment frame;

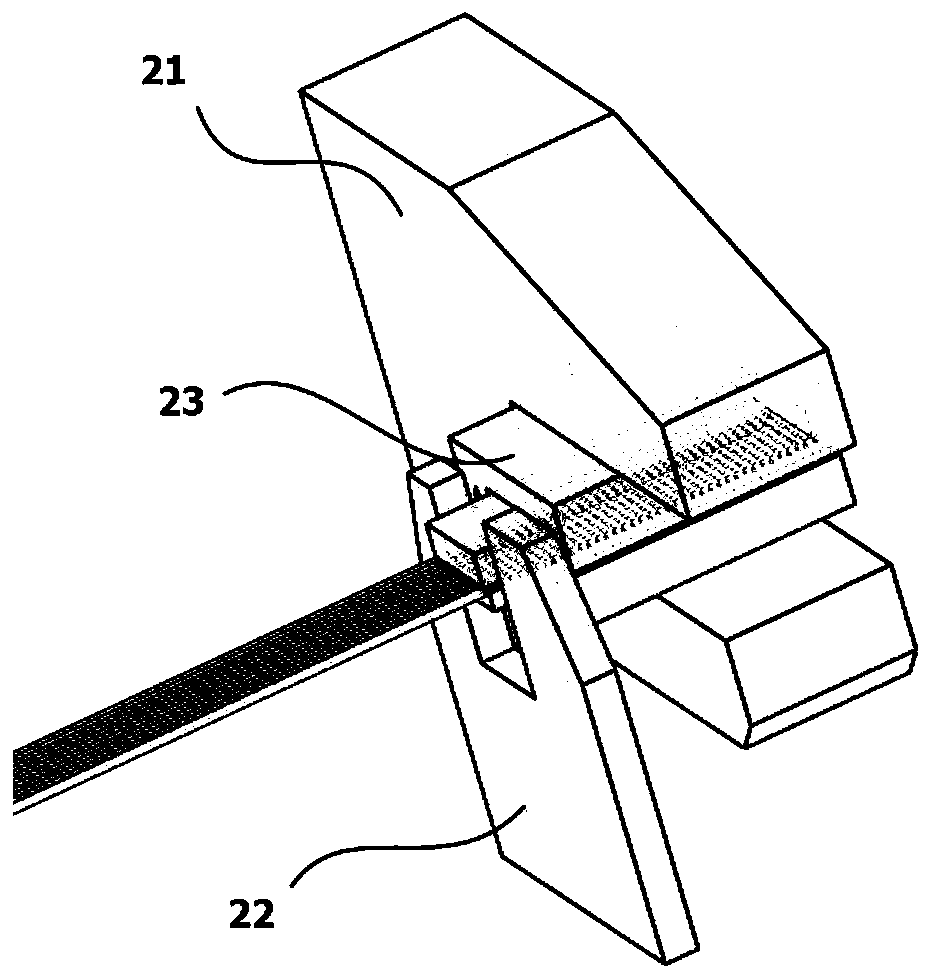

[0042] Further, a standard multi-core connector 23 with guide pin holes, such as figure 2 As shown, the photonic chip 51 is clamped by the fixture 41 and installed on the six-dimensional adjustment frame, and an optical amplification system 32 and a camera are placed, so that the end face of the multi-core connector 23 with guide pin holes can be photographed;

[0043] Further, adjust the six-dimensional adjustment frame to adjust the six degrees of freedom of left and right, front and rear, up and down, rotation, pitch, and swing respectively, so that the multi-core connector 23 with guide pin holes is para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com