A magnetic steel separation device and a separation method for a rotor of a permanent magnet motor

A permanent magnet motor and separation device technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as increased labor burden, increased cost, and component damage, so as to reduce labor burden, avoid damage, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

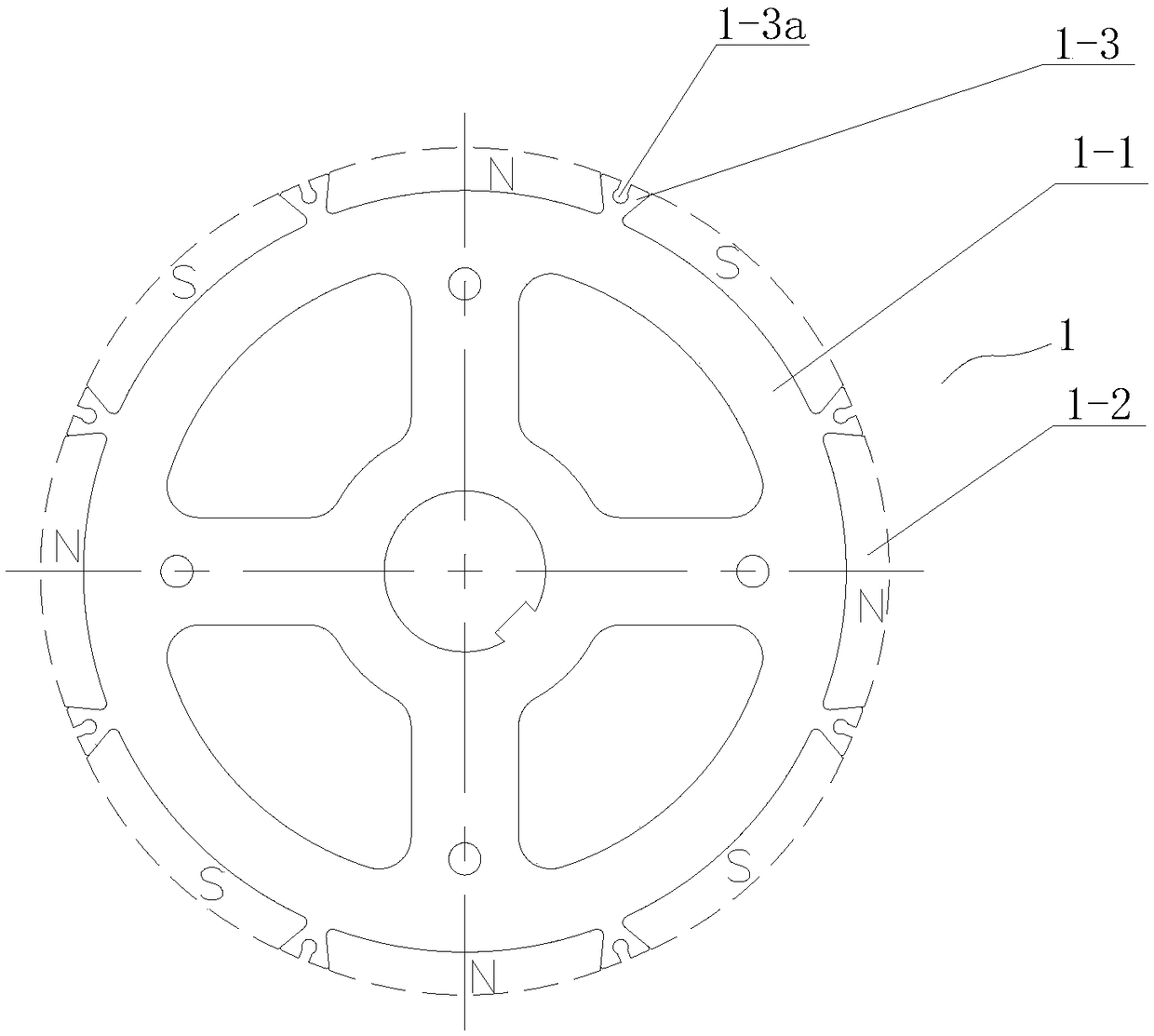

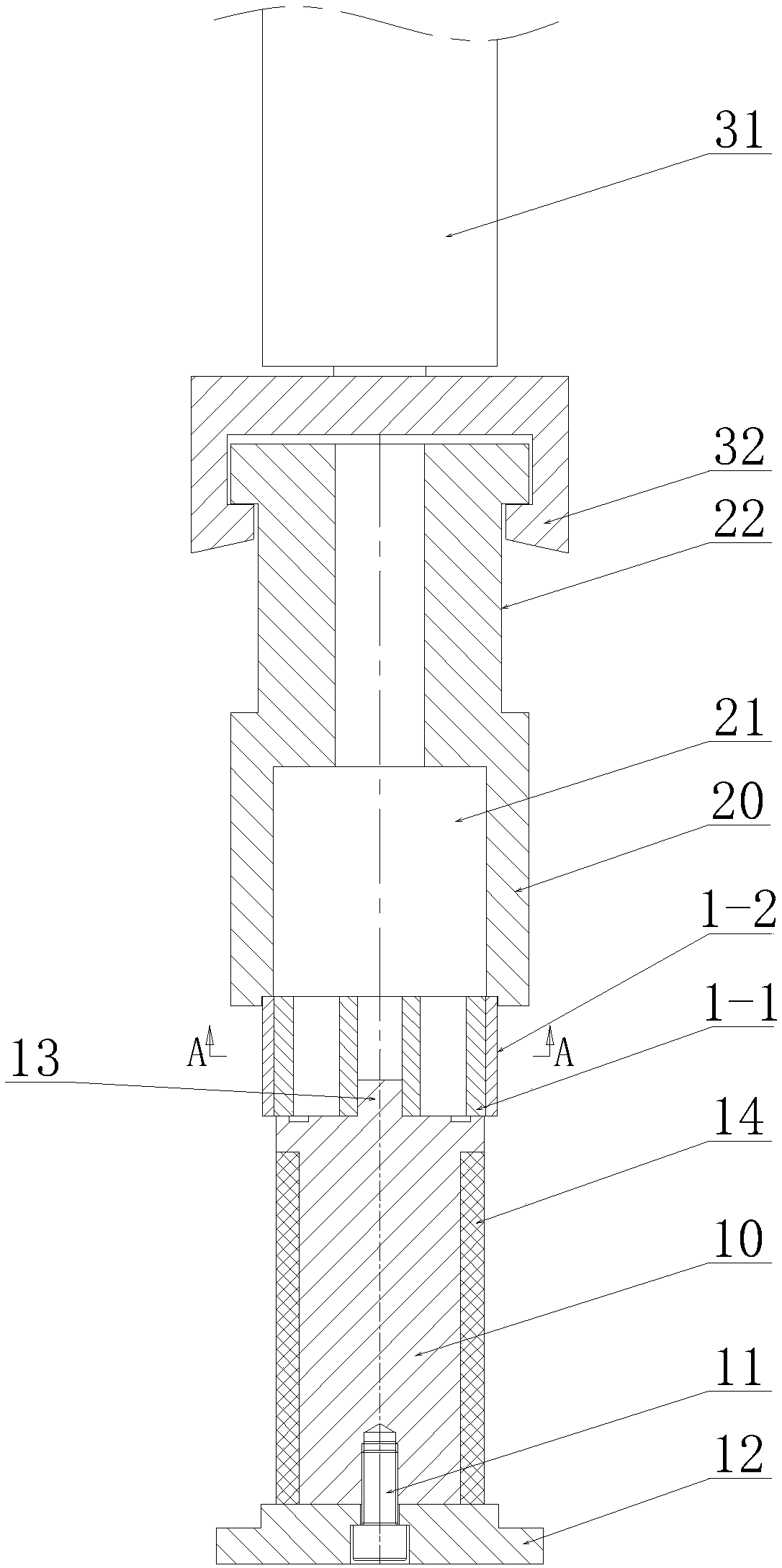

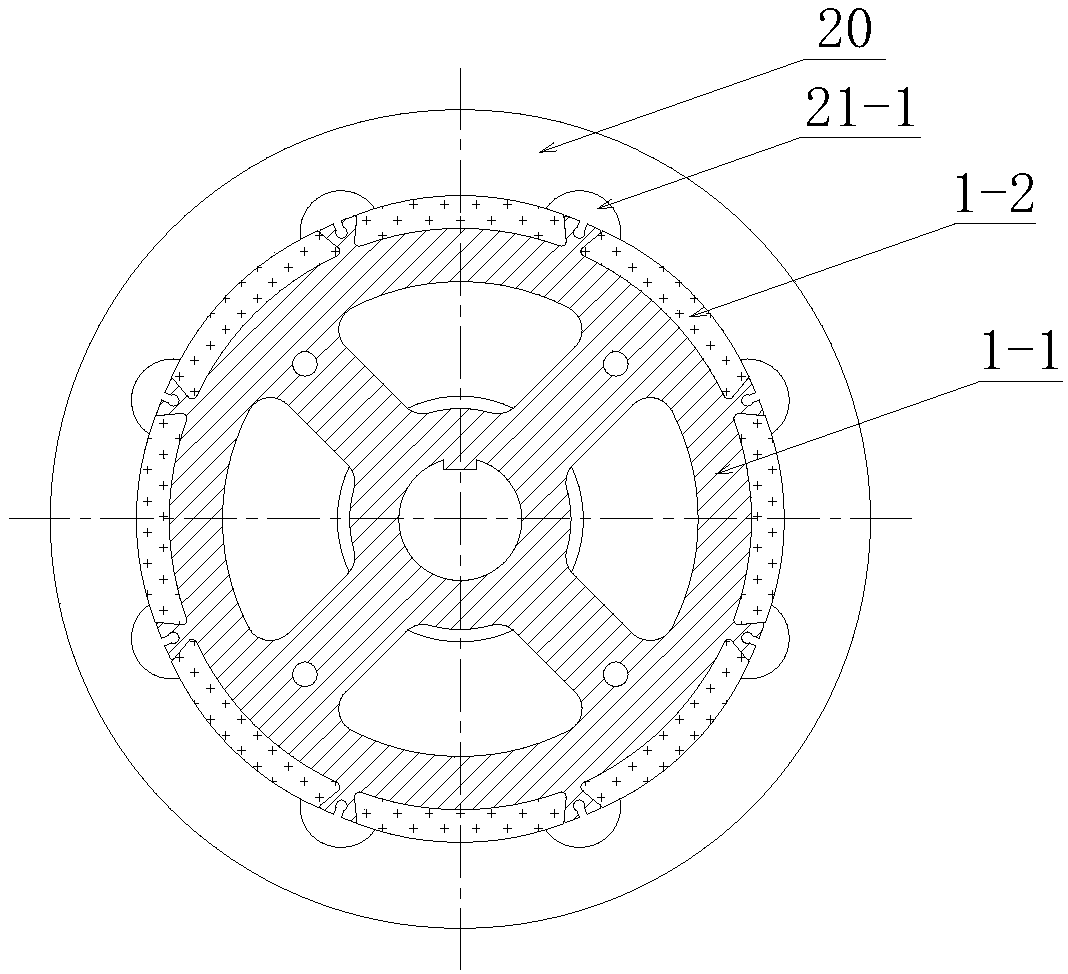

[0022] As shown in the figure, a permanent magnet motor rotor magnetic steel separation device includes a rotor positioning mold 10, the bottom of the rotor positioning mold 10 is installed on a fixed plate 12 through bolts 11, and the center of the upper end surface of the rotor positioning mold 10 is provided with Positioning boss 13; a lower pressing mold 20 is provided directly above the rotor positioning mold 10, and a cylindrical cavity 21 is provided at the lower part of the lower pressing mold 20 around the centerline, and the lower end opening of the cylindrical cavity 21 faces The upper end surface of the rotor positioning mold 10, and the center of the positioning boss 13 is located on the axis extension line of the cylindrical cavity 21, the diameter of the cylindrical cavity 21 is greater than or equal to the diameter of the rotary support body 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com