A preparation method of a high-performance high-speed permanent magnet synchronous motor iron core

A permanent magnet synchronous motor, high-performance technology, applied in the manufacture of stator/rotor bodies, etc., can solve the problems of increased production cost, waste, unreasonable material use, etc., and achieve the effect of reducing overall production cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

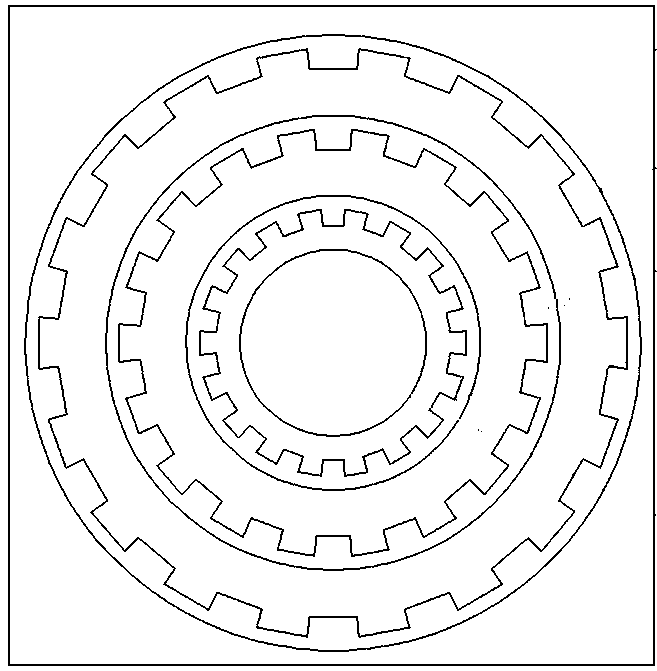

Image

Examples

Embodiment 1

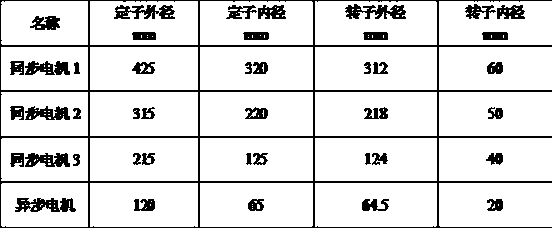

[0024] This embodiment includes three high-speed permanent magnet synchronous motors and an asynchronous motor, and the inner and outer diameters of its stator and rotor are as shown in Table 1;

[0025] surface Motor stator and rotor size

[0026]

[0027] Its preparation:

[0028] 1) Select material:

[0029] According to the model of the high-speed permanent magnet synchronous motor to be produced, the stator adopts a high magnetic induction silicon steel sheet with a magnetic induction of 1.66T, an iron loss of 1.95W / Kg, and a high frequency iron loss of P1.0 / 400 of 14.5W / Kg;

[0030] The rotor adopts a silicon steel sheet with a magnetic induction of 0.6T, a yield strength of 420MPa, and a tensile strength of 535MPa;

[0031] 2) Stamping into sheets: According to the specifications and models of each stator and rotor to be produced, the multiple stators on the selected material in step 1) are rationally arranged according to the size, and all the sheets are punche...

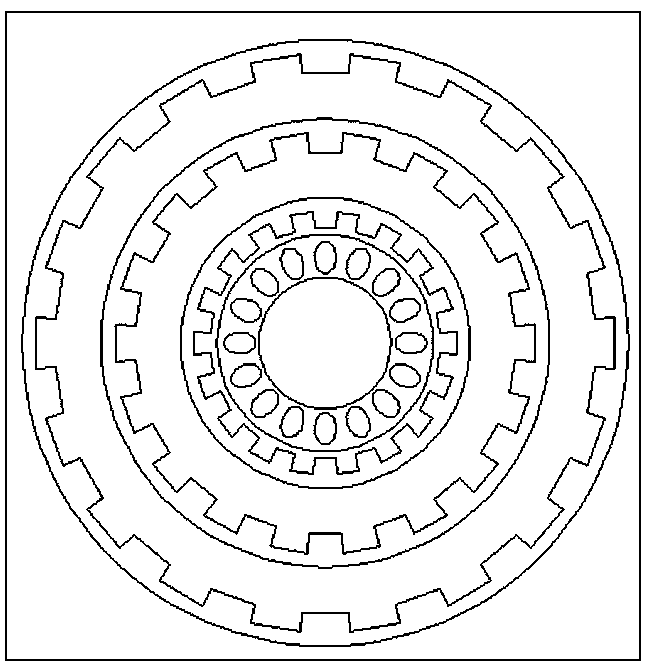

Embodiment 2

[0036] This embodiment includes three high-speed permanent magnet synchronous motors, and the inner and outer diameters of the stator and rotor are as shown in Table 2;

[0037] Table 2 Motor stator and rotor size

[0038]

[0039] Its preparation:

[0040] 1) Select material:

[0041] According to the model of the high-speed permanent magnet synchronous motor to be produced, the stator adopts a high magnetic induction silicon steel sheet with a magnetic induction of 1.69T, an iron loss of 1.91W / Kg, and a high frequency iron loss P1.0 / 400 of 14.2W / Kg;

[0042] The rotor adopts a silicon steel sheet with a magnetic induction of 0.9T, a yield strength of 445MPa and a tensile strength of 565MPa;

[0043] 2) Stamping into sheets: According to the specifications and models of each stator and rotor to be produced, the multiple stators on the selected material in step 1) are rationally arranged according to the size, and all the sheets are punched at one time; and then the multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic sense | aaaaa | aaaaa |

| Magnetic sense | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com