Method for operating a piezoelectric actuator as a sensor and a motor vehicle

A piezoelectric actuator and sensor technology, applied in the direction of machines/engines, engine components, combustion engines, etc., can solve the problems of low signal-to-noise ratio, loss, etc., to increase the signal-to-noise ratio, improve the ability, and reduce the defective rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

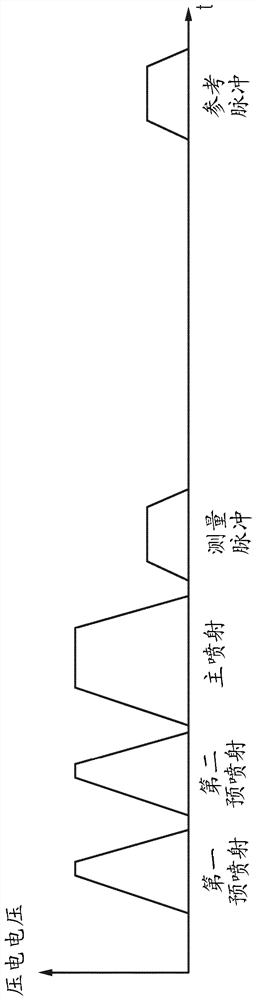

[0033] figure 1 A graph showing a typical injection pattern with a measurement pulse and a reference pulse. In this context, a first pilot injection, a second pilot injection and a main injection are assumed. Measurement pulses are generated at locations where the usable signal to be measured is expected. Then, a reference pulse corresponding to the measurement pulse is generated.

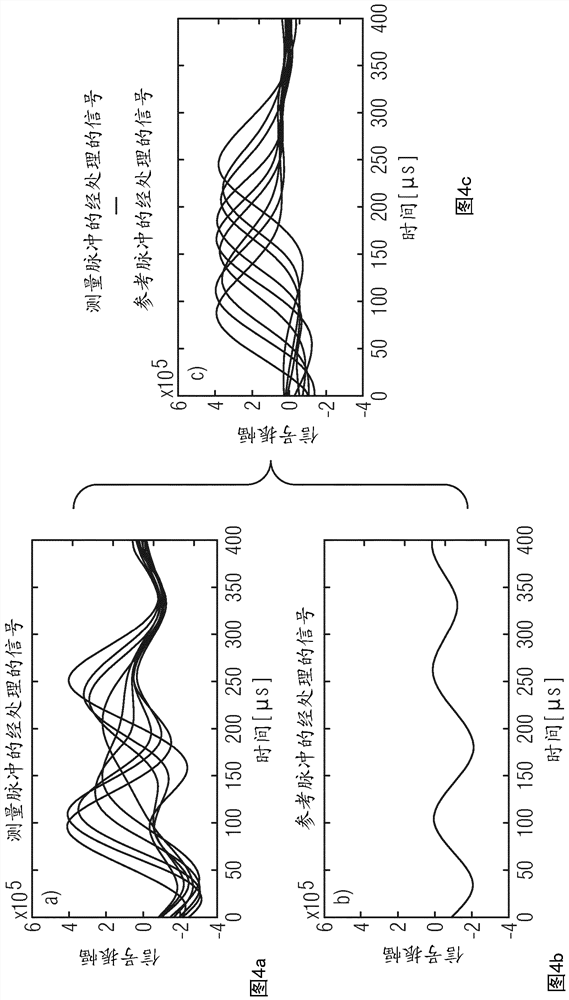

[0034] figure 2 The change in the position of the measurement pulse is shown in the corresponding figure.

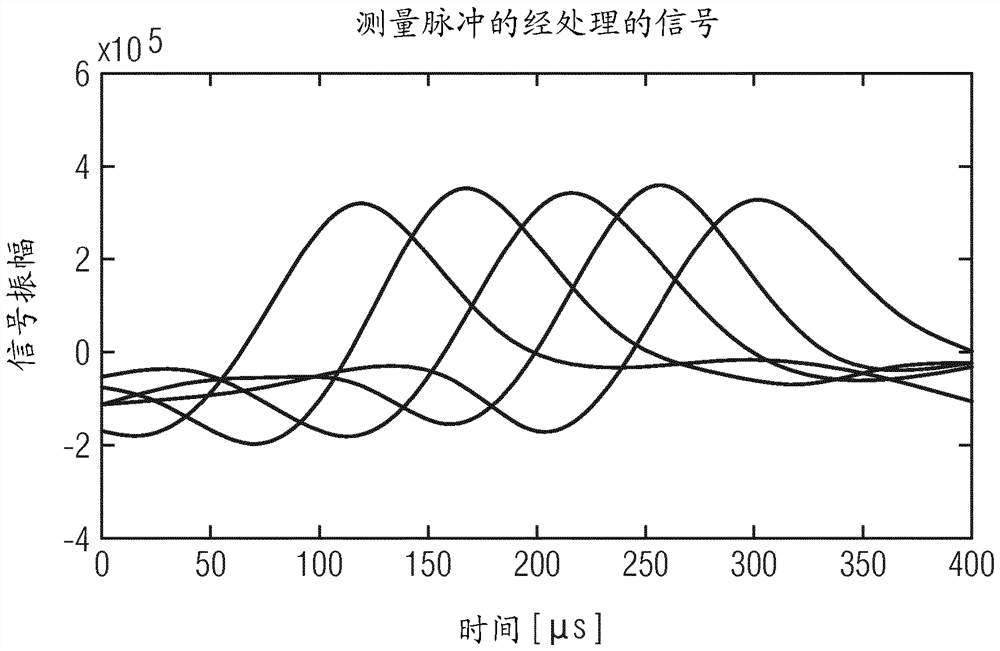

[0035] image 3 The processed signal of a measurement pulse of an injector with a high signal-to-noise ratio is shown. The different curves relate to different positions of the measurement pulses (see also figure 2 ).

[0036] This is an injector whose signal has only very little noise due to charging of the piezoelectric actuator. This can be recognized from the fact that when the relative position of the measurement pulse changes (the phase relationship between the closing of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com