Systems, methods, and computer program products for identifying defects in manufactured components using locally adaptive thresholds

A technology of computers and computer processors, which is applied in the field of detecting defects in manufacturing components, and can solve problems such as limiting the sensitivity of inspection algorithms, not having enough representativeness, and complex design patterns in logic areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

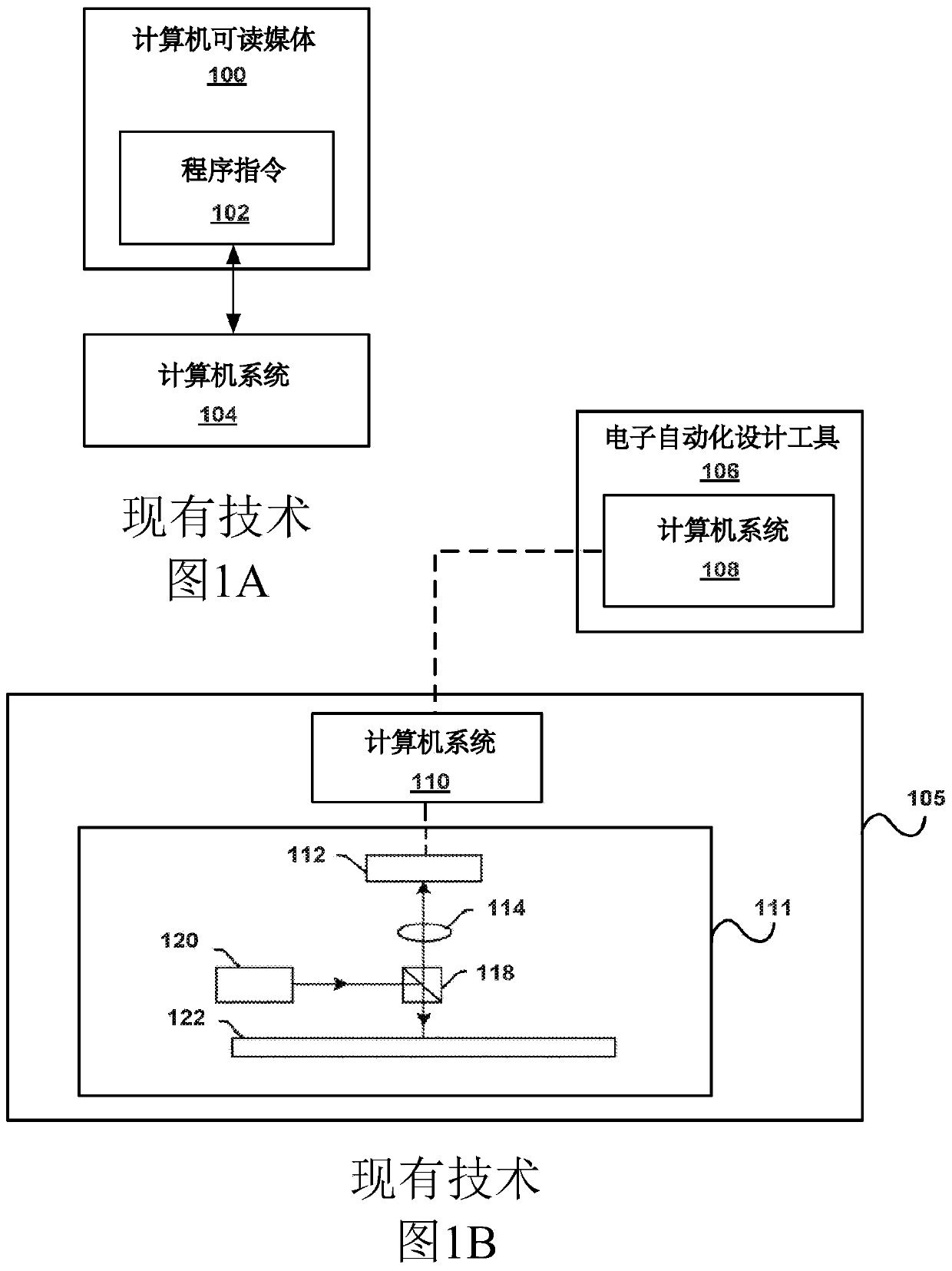

[0016] The following description discloses systems, methods, and computer program products provided for identifying manufacturing component defects using locally adaptive thresholds. It should be noted that any integrated and / or separate computer and inspection system (e.g., wafer inspection, master reticle inspection, laser scanning inspection system, etc.) (e.g., Figure 1A This system, method and computer program product are implemented in the context of the inspection system described in B), including the various embodiments described below.

[0017] Additional embodiments relate to a non-transitory computer-readable medium storing program instructions executable on a computer system to perform a computer-implemented method for identifying manufacturing component defects using locally adaptive thresholds. Figure 1A An example of this is shown in . Specifically, as Figure 1A Shown in , computer readable medium 100 embodies program instructions 102 executable on computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com