High frequency heating device

A high-frequency heating device, surface wave technology, applied in the direction of electric heating device, microwave heating, electric/magnetic/electromagnetic heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0029]

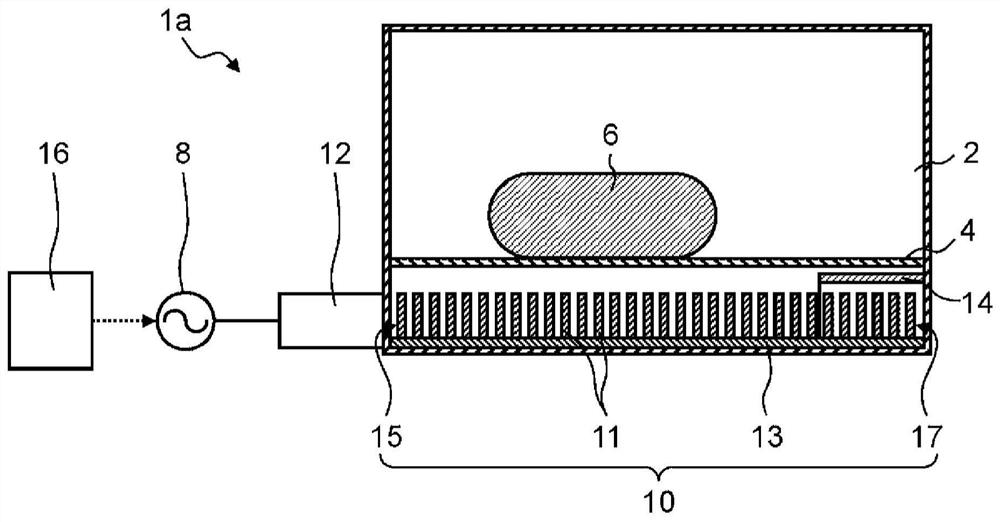

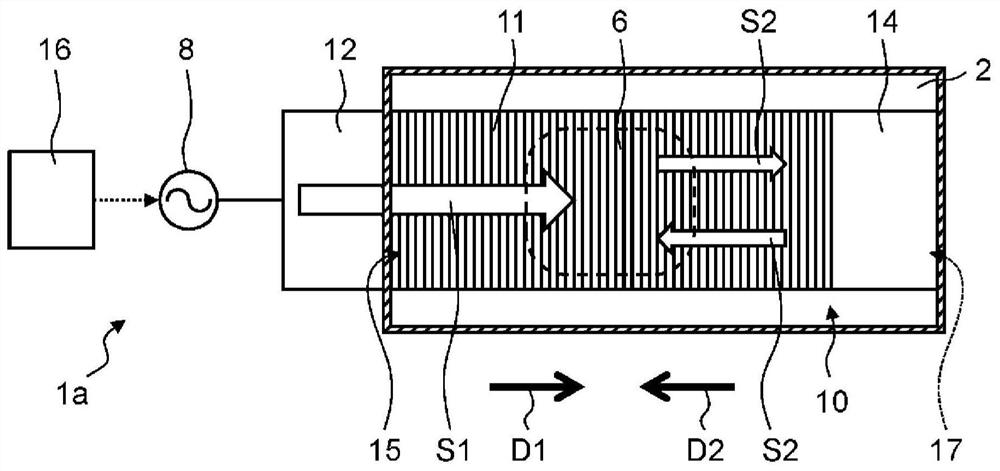

[0030] figure 1 , figure 2 It is a vertical cross-sectional view and a horizontal cross-sectional view schematically showing the structure of the high-frequency heating device 1 a according to Embodiment 1 of the present invention, respectively.

[0031] Such as figure 1 , figure 2 As shown, the high-frequency heating device 1 a has a heating chamber 2 , a generation unit 8 , a surface wave excitation body 10 , a coupling unit 12 , a reflection unit 14 , and a control unit 16 . The high-frequency heating device 1 a is configured to heat the object to be heated 6 placed on the mounting table 4 with microwaves propagating in the surface wave mode on the surface of the surface wave exciter 10 .

[0032] in addition, figure 2 Schematically shows the situation in which microwaves in the surface wave mode propagate on the surface wave excitation body 10, and the heating object 6 is placed on the mounting table 4 (in the figure 2 not shown in the figure).

[0033...

Embodiment approach 2

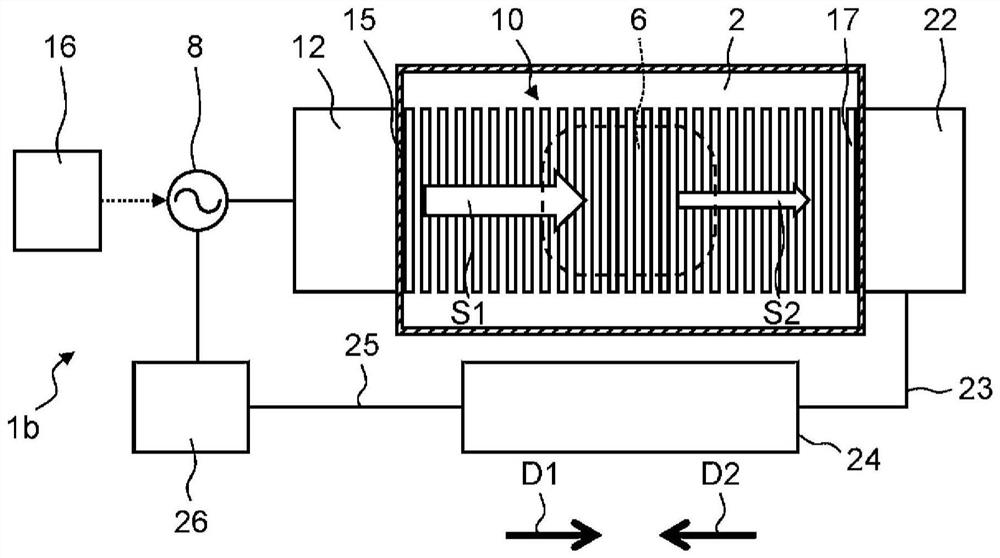

[0056] Regarding the high-frequency heating device 1b according to Embodiment 2 of the present invention, the differences from Embodiment 1 will be mainly described. image 3 It is a cross-sectional view schematically showing the structure of the high-frequency heating device 1b. image 3 Schematically shows the situation in which microwaves in the surface wave mode propagate on the surface wave excitation body 10, and the heating object 6 is placed on the mounting table 4 (in the image 3 not shown in the figure).

[0057] In Embodiment 1, microwaves are reused by reflecting the surface wave S2 that has reached the end side 17 of the surface wave excitation body 10 . On the other hand, in Embodiment 2, microwaves are reused by converting microwaves in the surface wave mode into microwaves in another mode by impedance matching.

[0058] Such as image 3 As shown, the high-frequency heating device 1 b has a matching unit 22 and a converting unit 24 instead of the reflecting ...

Embodiment approach 3

[0070] Regarding the high-frequency heating device 1 c according to Embodiment 3 of the present invention, the difference from Embodiment 2 will be mainly described. Figure 4 It is a cross-sectional view schematically showing the structure of the high-frequency heating device 1c. Figure 4 Schematically shows the microwave propagation of the surface wave mode on the surface wave excitation body 20, and the heating target object 6 on the mounting table 4 (on Figure 4 not shown in the figure).

[0071] Such as Figure 4 As shown, the high-frequency heating device 1 c does not have the conversion unit 24 and the power storage unit 26 , but has a coupling unit 32 instead. The high-frequency heating device 1 c has a surface wave exciter 20 instead of the surface wave exciter 10 . The surface wave exciter 20 has a structure different from that of the surface wave exciter 10 according to the second embodiment. The coupling part 32 corresponds to the second coupling part.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com