Dedusting device for production of microcrystalline waterproof agents

A technology of dust removal device and water repellent, which is applied in the directions of transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., which can solve the problems of inconvenient use of dust removal device, lack of dust recovery ability of microcrystalline water repellent agent, poor recovery effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

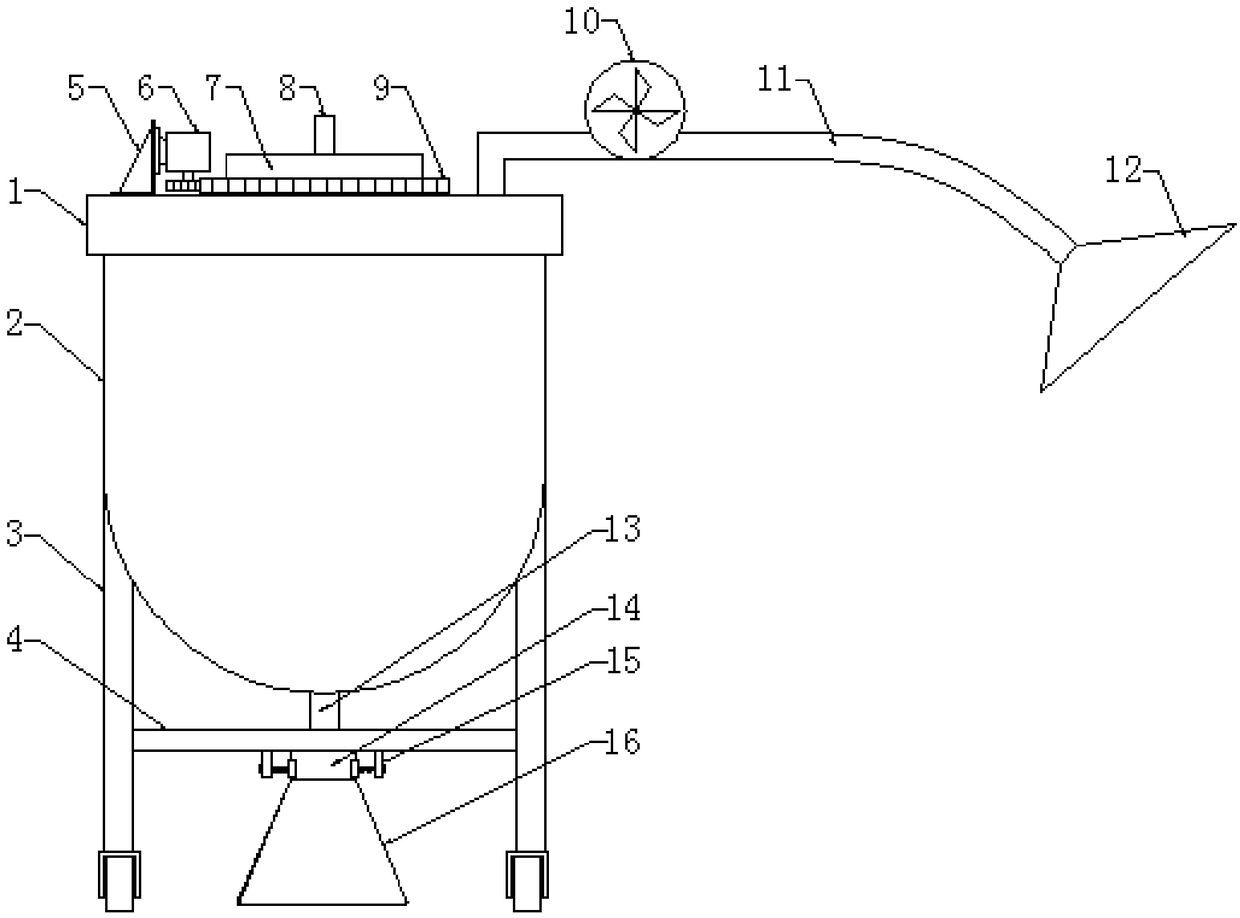

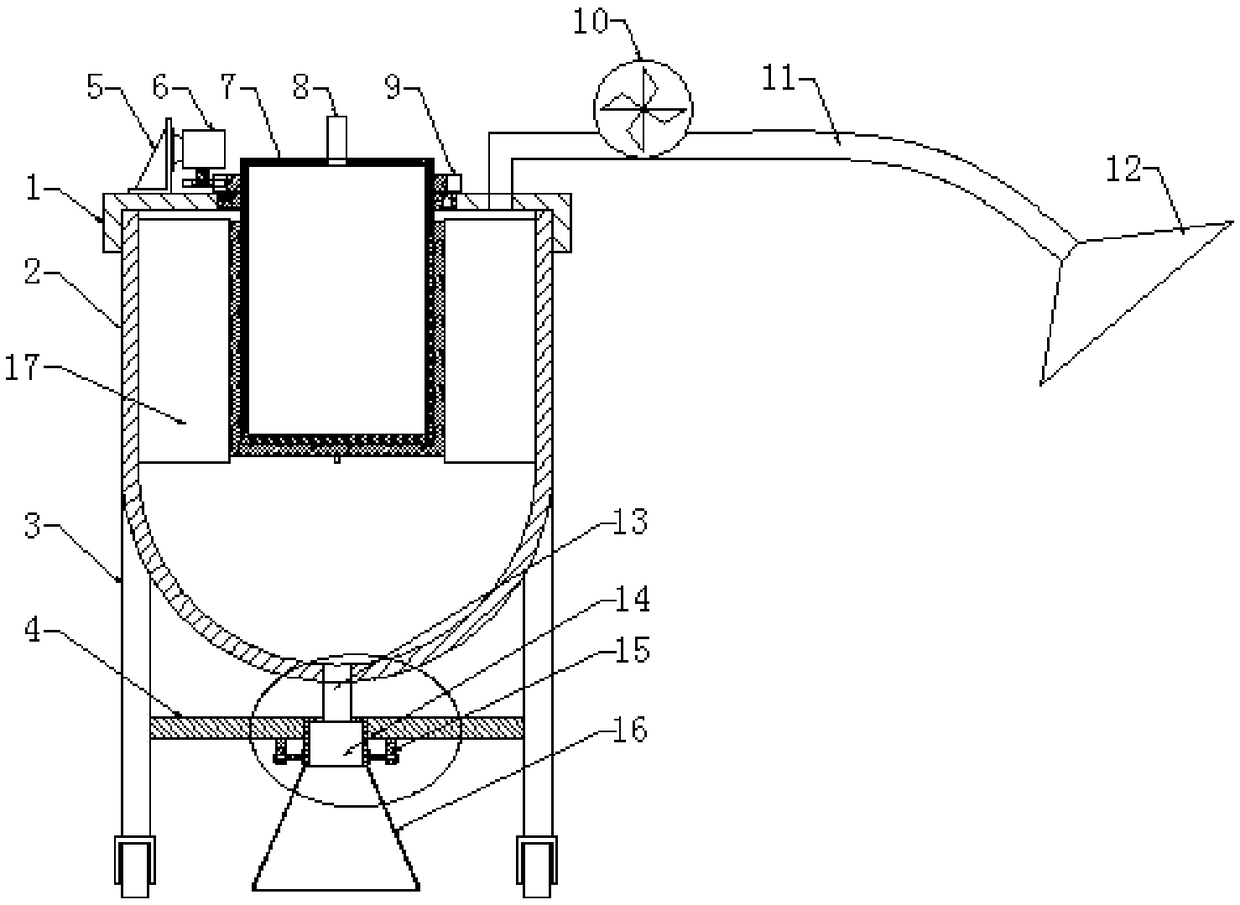

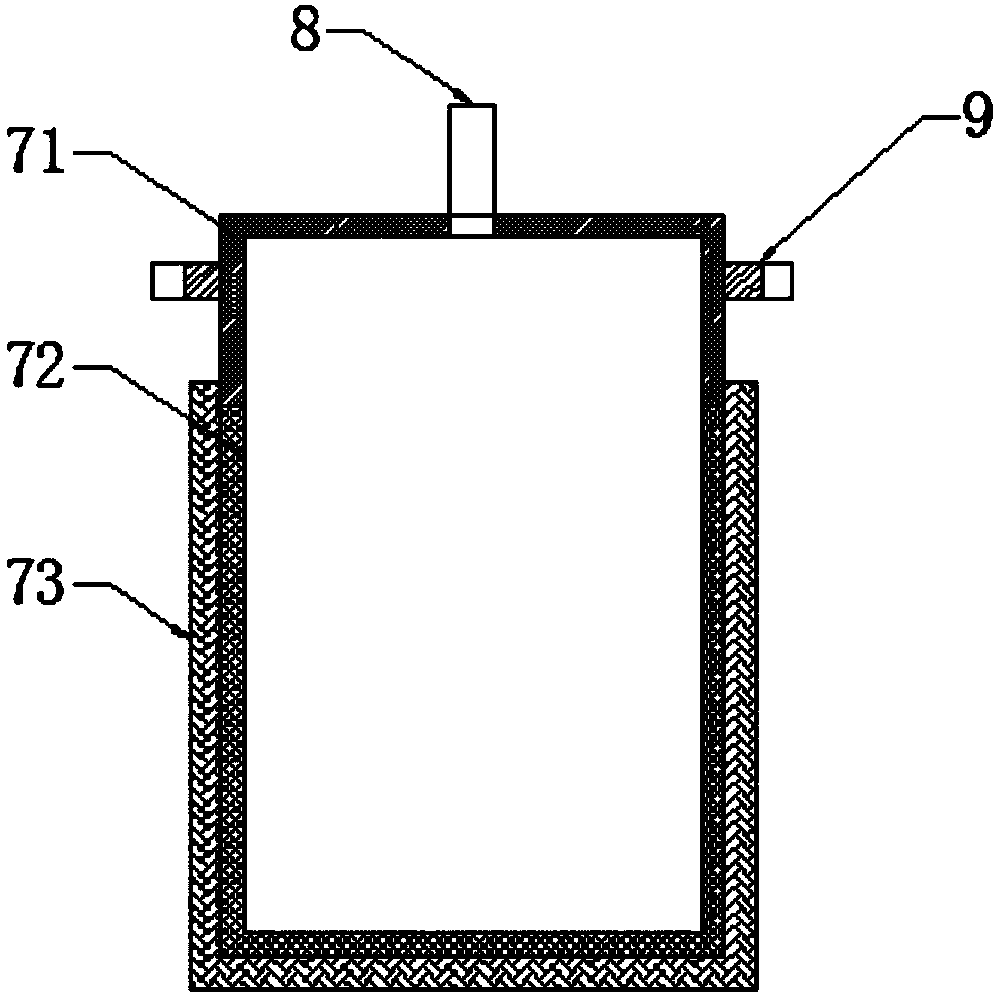

[0029] Embodiment 1, with reference to figure 1 , figure 2 , image 3 with Figure 4As shown, a dust removal device for microcrystalline waterproofing agent production includes a dust collection tank 2, a suction hood 12 and a collection bag 16. The lower end of the dust collection tank 2 is set in a hemispherical shape to facilitate dust concentration, and the dust collection tank 2 is made of stainless steel. The material is made of good rust resistance, the upper mask of the dust collection tank 2 is provided with a tank cover 1 to cover the dust collection tank 2, and the inner center of the dust collection tank 2 is provided with a filter cartridge 7 pairs to enter the dust collection The gas in the tank 2 is filtered, and the upper end of the filter cylinder 7 is set as a reinforcement cylinder 71 to strengthen the filter cylinder 7, and the ring gear 9 is fixedly sleeved on the outside of the reinforcement cylinder 71, and the lower end of the reinforcement cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com