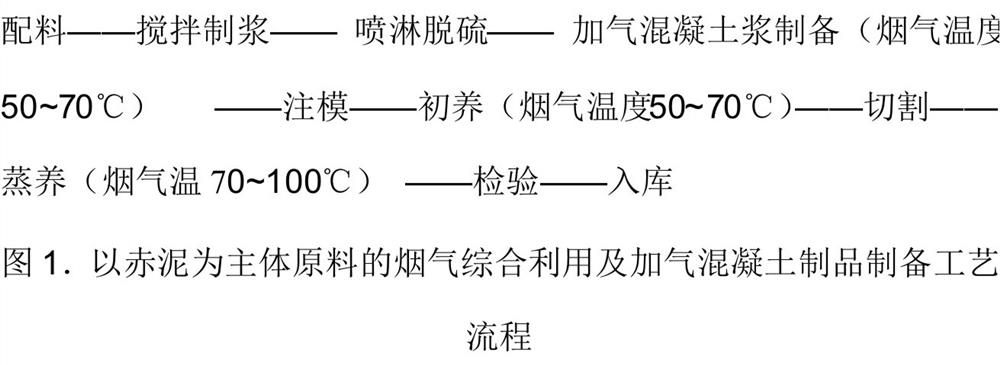

Flue gas comprehensive utilization and aerated concrete product preparation process taking red mud as main raw material

A technology of air-entrained concrete, preparation process, applied in the direction of ceramic products, applications, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] Example 1. With red mud powder as the main raw material, with fly ash powder, quicklime, 52.5 ordinary Portland cement, polished brick waste residue, water glass, cellulose sodium, cement water reducer, air entraining agent, foam stabilizer, Comprehensive utilization technology of ceramic kiln flue gas and aerated concrete products with water as raw material. Comprehensive utilization includes kiln waste heat utilization, desulfurization, dust removal, and alumina industrial red mud, polishing waste, fly ash, and renewable aerated concrete products.

[0017] During production, 60% of red mud powder, 10% of fly ash, 10% of quicklime powder, 10% of 52.5 ordinary Portland cement, 10% of polished brick waste, 0.5-2% of water glass, and 0.1-0.3% of sodium cellulose , Cement superplasticizer 0.1~0.5%, and water with a material-to-water ratio of 0.60~0.7 are added to the continuous mixing mixer according to a certain formula component ratio to prepare a certain concentration o...

example 2

[0024] Example 2. With red mud powder as the main raw material, zeolite powder, quicklime, 52.5 ordinary Portland cement, polished brick waste residue, water glass, cellulose sodium, cement water reducer, air entraining agent, foam stabilizer, water, etc. Ceramic kiln flue gas comprehensive utilization technology and aerated concrete products as raw materials. Comprehensive utilization includes kiln waste heat utilization, desulfurization, dust removal, and alumina industrial red mud, polishing waste, fly ash, and renewable reinforced concrete products.

[0025] During production, 70% of red mud powder, 10% of zeolite powder, 8% of quicklime powder, 6% of 52.5 ordinary Portland cement, 6% of polished brick waste residue, 0.5-2% of water glass, 0.1-0.3% of cellulose sodium, Cement superplasticizer 0.1~0.5%, and water with a material-to-water ratio of 0.60~0.65 are added to the continuous mixing mixer according to a certain formula component ratio to prepare a certain concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com