Forced cooling gas steel pipeline pressure repair welding method

A technology of forced cooling and welding methods, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of residents' production, life inconvenience, gas supply interruption, etc., achieve convenient maintenance, reduce possibility, and avoid losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

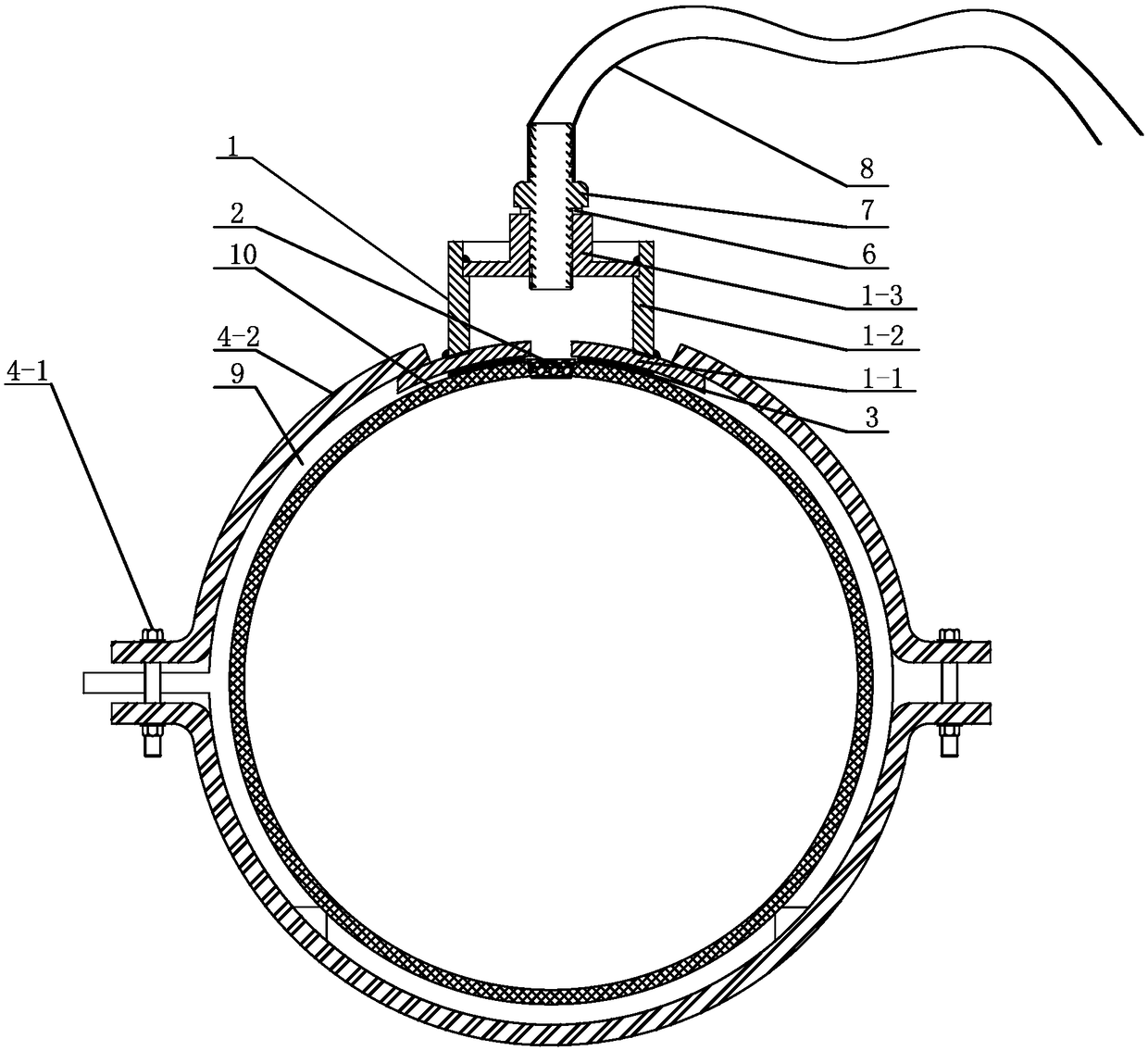

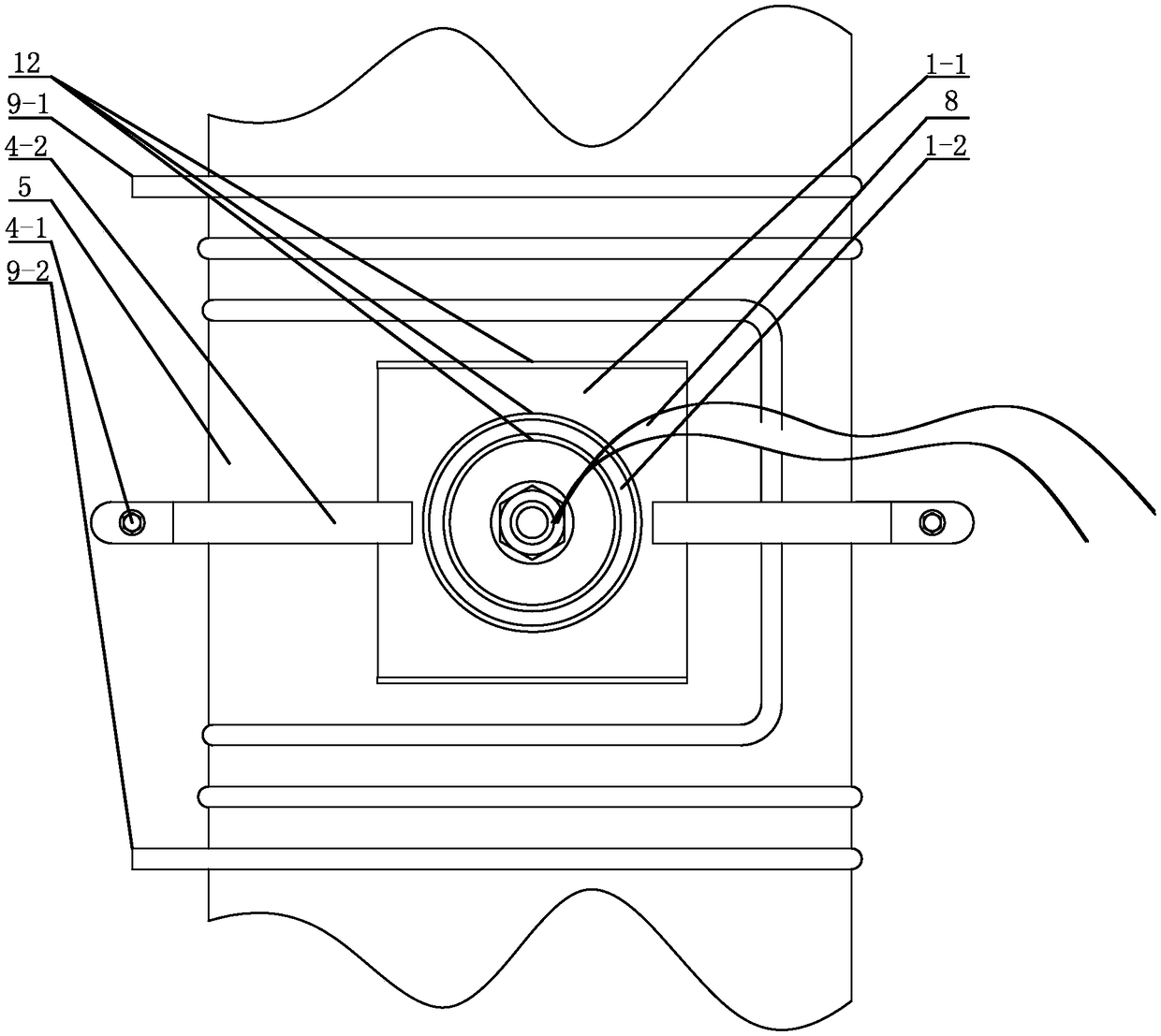

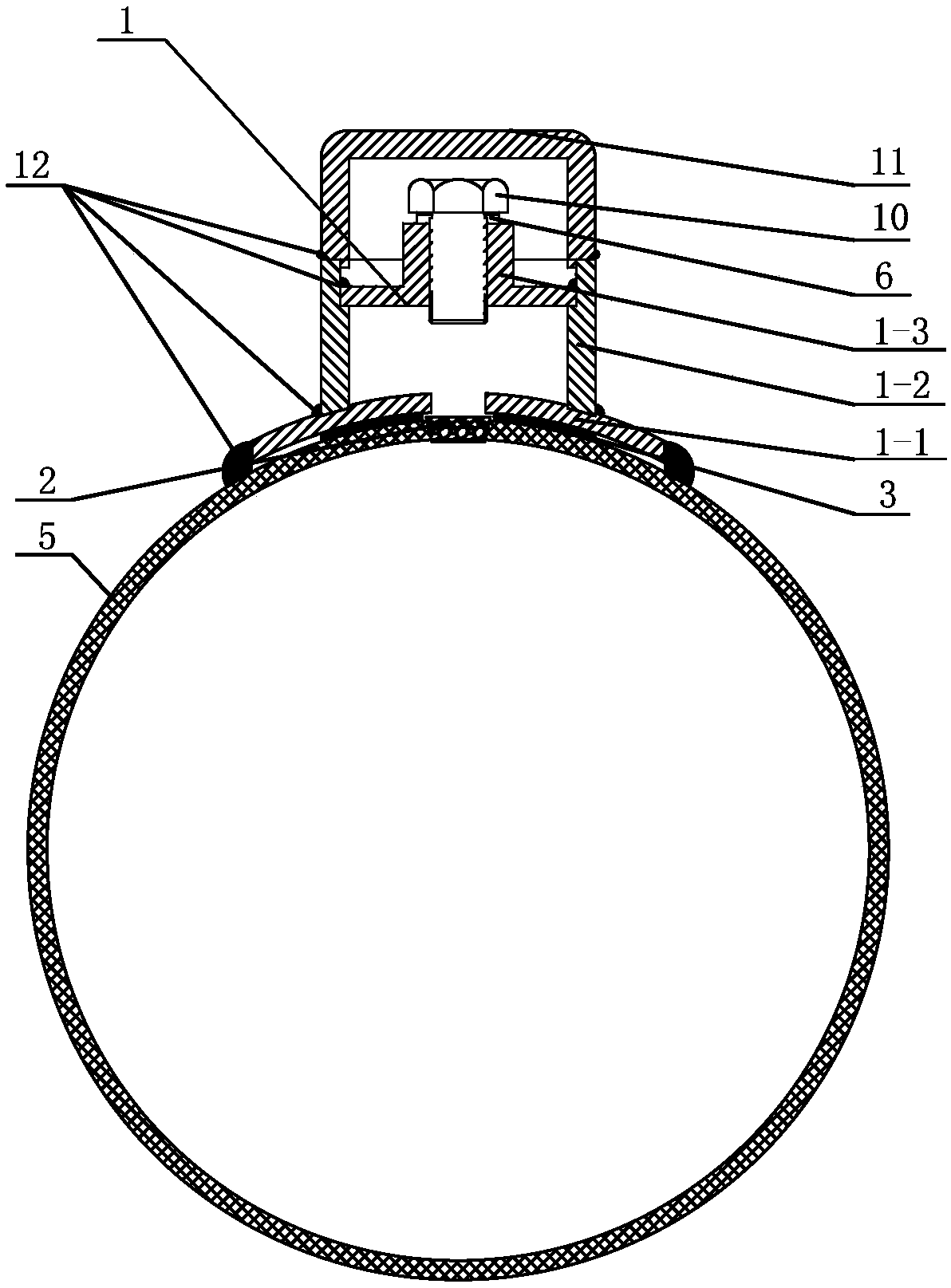

[0022] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, a forced cooling gas steel pipeline repair welding method under pressure in this embodiment, the forced cooling steel gas pipeline repair welding method under pressure is realized according to the following steps:

[0023] Step 1. Prefabricate the plugging base 1 according to the size of the leakage port of the main pipeline 5, and the plugging base 1 includes an arc patch 1-1, a lower plugging cap 1-2 and a drainage flange 1-3, The center of the arc patch 1-1 is provided with a leakage hole, the lower surface of the arc patch 1-1 fits the outer wall of the main pipeline 5 to be repaired, and the leakage hole at the center of the arc patch 1-1 is in contact with the parent pipeline. 5 Corresponding to the leakage port, the lower sealing cap 1-2 is welded and sealed with the upper end surface of the arc patch plate 1-1, and the upper inner side wall of the lower sealing cap 1-2 is weld...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination figure 1 , figure 2 and Figure 4 Describe this embodiment, a kind of forced cooling gas steel pipeline pressure repair welding method of this embodiment, in step 1, the size of the leakage hole in the center of the arc repair plate 1-1 is based on the size of the leakage point of the main pipeline 5 Depends, the edge distance band of the edge 5-10mm of the leakage point of the parent pipeline 5 to be repaired is the edge of the leakage hole at the center of the circular arc repair plate 1-1. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination figure 1 , figure 2 and Figure 4 This embodiment will be described, which is a pressure repair welding method for a forced cooling gas steel pipeline in this embodiment. In step 1, the drainage flange 1-3 is a standard component, the outer diameter of the drainage flange 1-3 is 70-100mm, and the drainage flange 1-3 is provided with an internal threaded hole with a diameter of 15mm. The drainage method The diameter of the blue 1-3 is the same as that of the lower plug cap 1-2. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com