Novel wood protection agent

A protective agent and wood technology, applied in the direction of wood impregnation, wood impregnation, wood processing appliances, etc., can solve the problems of increasing the power consumption of the device, covering a large area, and having a complex structure, reducing power consumption and achieving high linkage. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

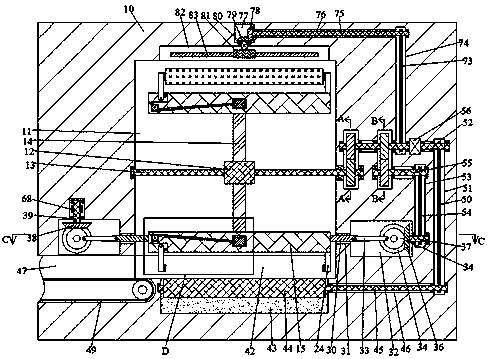

[0014] Combine below Figure 1-6 The present invention will be described in detail.

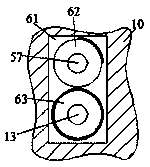

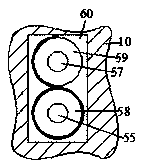

[0015] refer to Figure 1-6 , according to an embodiment of the present invention, a new type of wood protection agent, including a body 10, a rotating chamber 11 is provided in the body 10, a rotating wheel 12 is arranged in the rotating chamber 11, and the axis of the rotating wheel 12 is A rotating shaft 13 whose left end is rotatably connected to the left end wall of the rotating chamber 11 is fixedly provided, and the right side of the rotating chamber 11 communicates with a first transmission chamber 61, and the right end of the rotating shaft 13 extends into the transmission chamber 61 and A first gear 63 is fixed, and the upper end of the first gear 63 is meshed with a first irregular tooth 62 with a quarter tooth. The axis of the first irregular tooth 62 is fixed with a left end and the The first rotating shaft 57 connected to the left end wall of the first transmission chamber 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com