A transport device which is convenient to limit the stamping parts of automobiles

A technology for automobile stamping parts and transportation devices, which is used in transportation and packaging, trolley accessories, trolleys, etc., can solve the problems of stamping parts colliding with each other, surface accuracy damage of stamping parts, and single function, so as to avoid conflicting wear and improve functionality. , to ensure the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

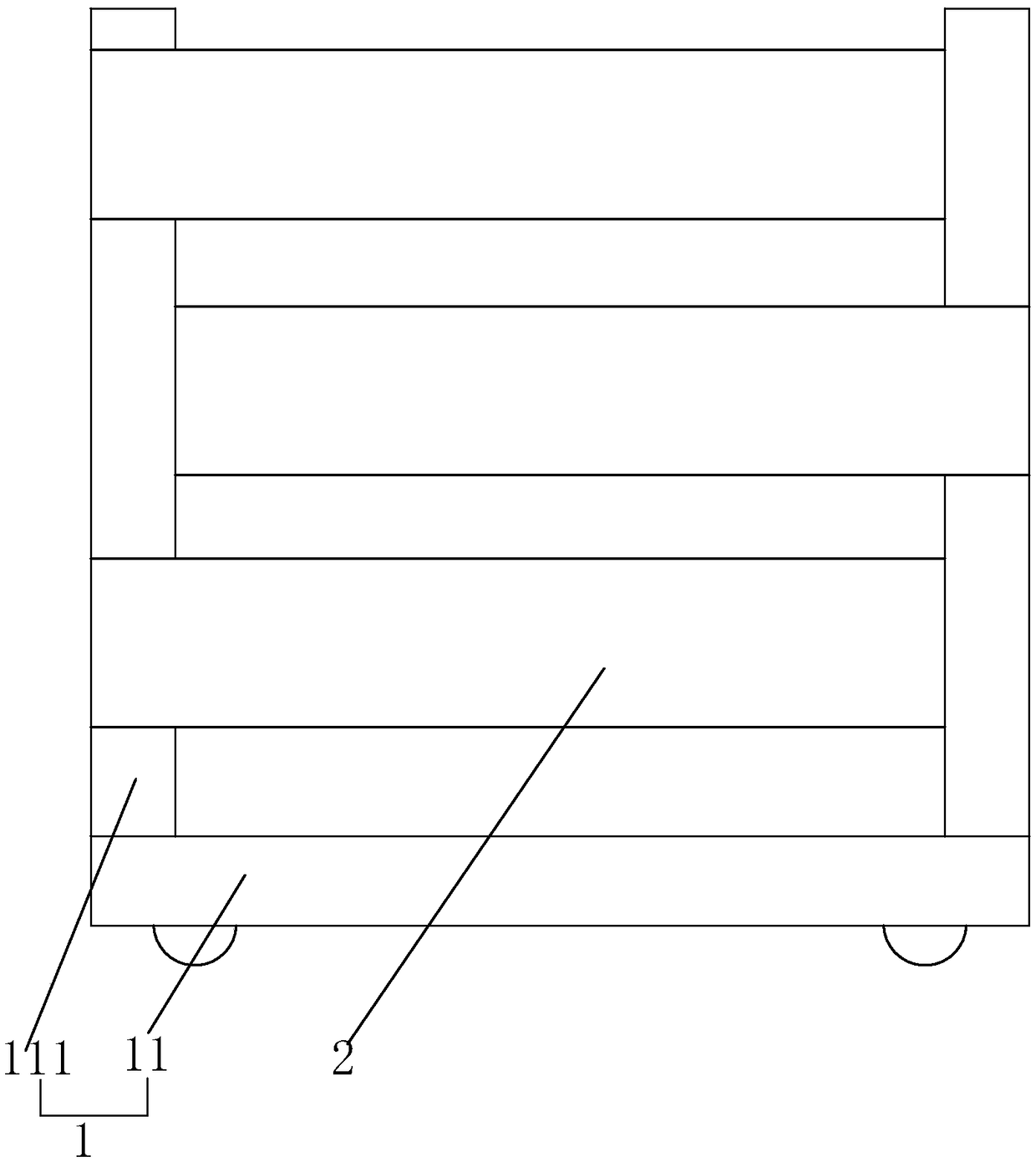

[0022] Embodiment 1: A transportation device that facilitates the positioning of automobile stamping parts, such as figure 1 As shown, a transport vehicle 1 is included, and the transport vehicle 1 includes a vehicle frame 11. The vehicle frame 11 includes two parallel support rods 111, and the vehicle frame 11 is provided with a multi-layer storage frame 2, that is, the storage frames 2 are staggered and rotated respectively. On the support rod 111 , it is possible to rotate a plurality of storage frames 2 to mutually staggered positions, without causing mutual space obstruction, and it is convenient for the staff to transport and store the stamping parts 8 in the storage frame 2 conveniently.

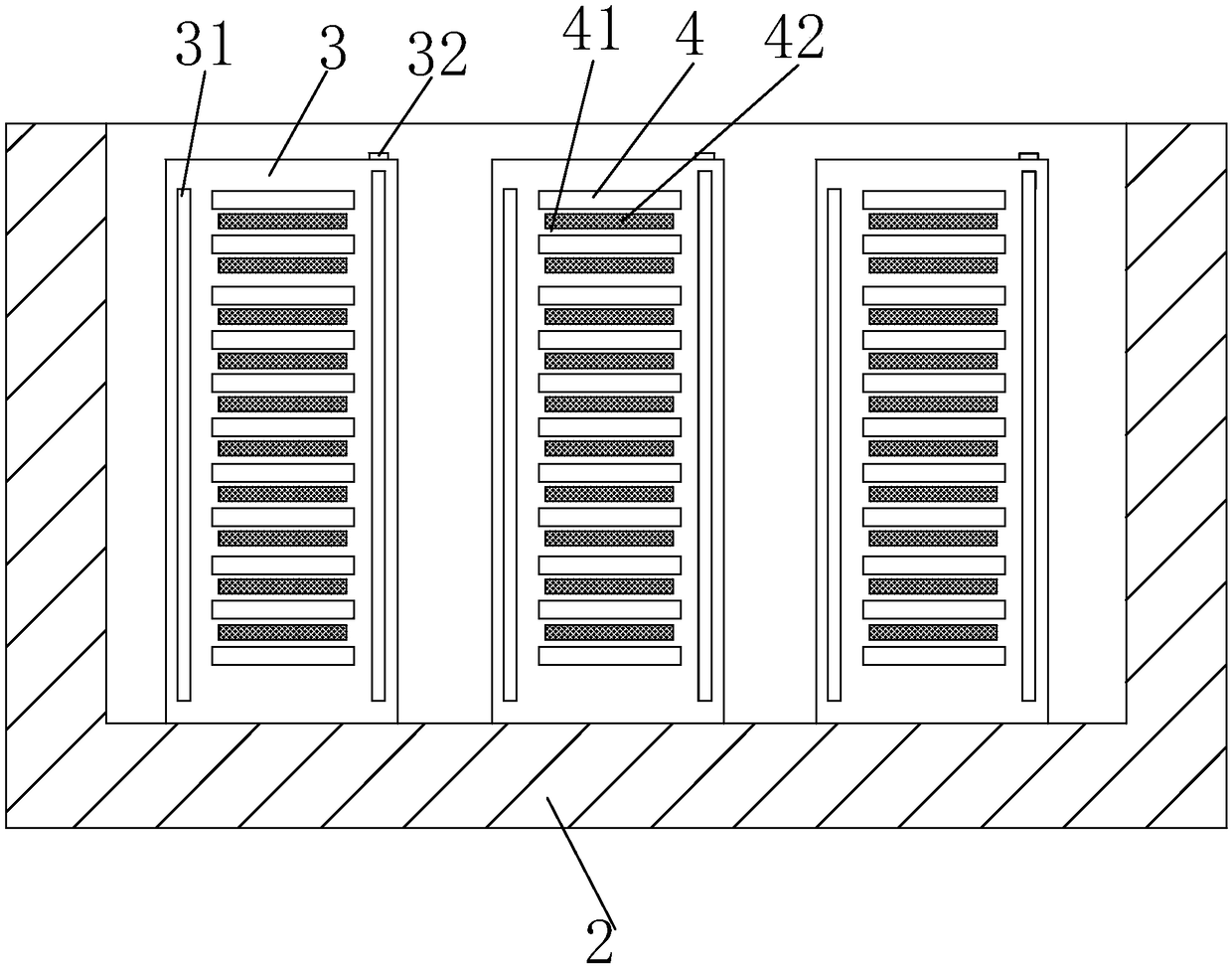

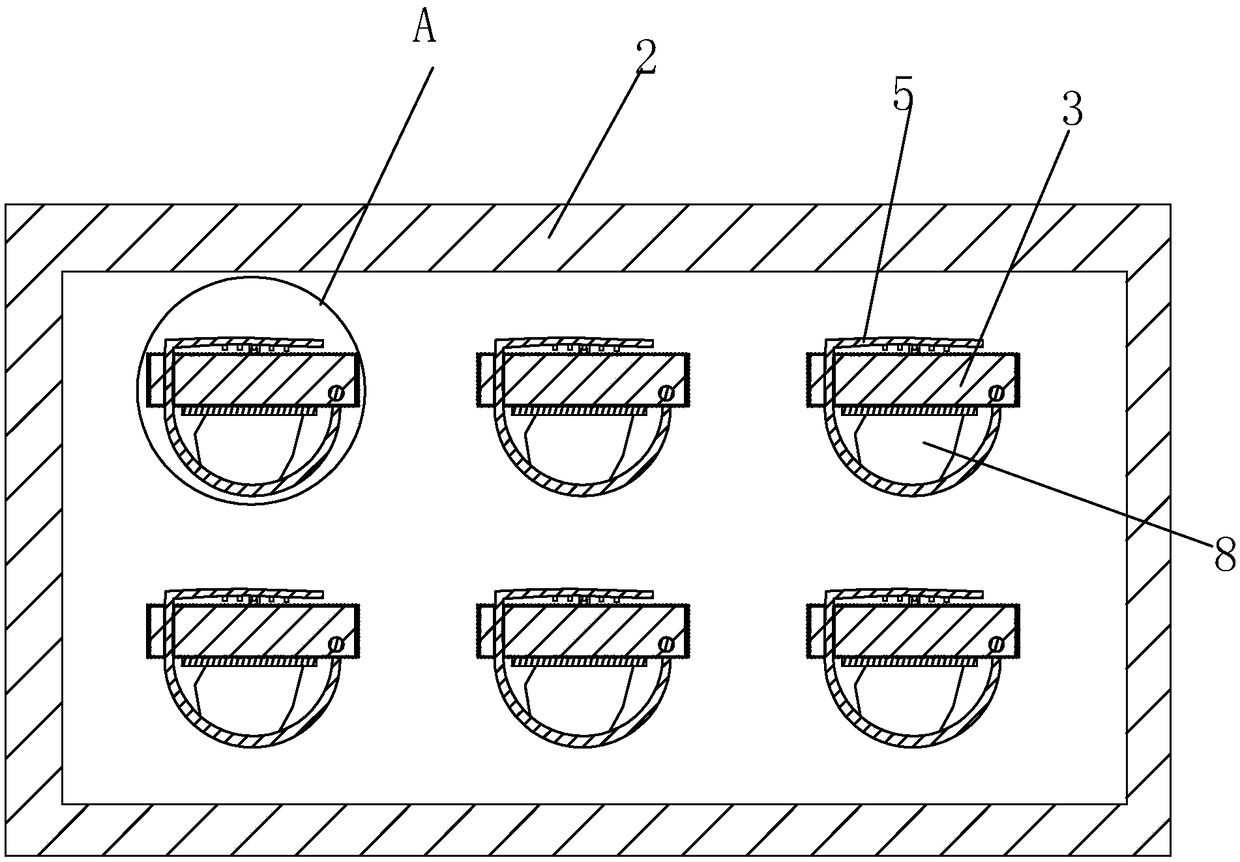

[0023] Such as figure 2 and 3 As shown, at this time, a plurality of support plates 3 are arrayed on the storage frame 2, and a plurality of limit support blocks 4 are arrayed on the side wall of the support plate 3 along its thickness and along its height direction. A limit groove...

Embodiment 2

[0028] Embodiment 2: A transportation device that facilitates the positioning of automobile stamping parts. The difference from Embodiment 1 is that, as Figure 4 As shown, at this time, the outer surface of the support plate 3 is coated with an insect repellent coating 97, and the surface of the insect repellent coating 97 is also coated with a distinguishing pigment layer, and the outer surfaces of different support plates 3 are coated with different colors. Pigment layer; insect repellent coating 7 can effectively prevent mosquitoes from approaching, and is convenient for long-term storage of stamping parts 8 in this transportation device; The storage in the device allows quick record differentiation, which further improves the functionality of the present and transport device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com