Radioactive waste solidification base material and preparation method of solidified glass

A technology for radioactive waste and basic materials, applied in the field of radioactive waste treatment and disposal, can solve problems that have not been reported in the literature, and achieve the effects of low crushing value, strong corrosion resistance, and stable chemical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

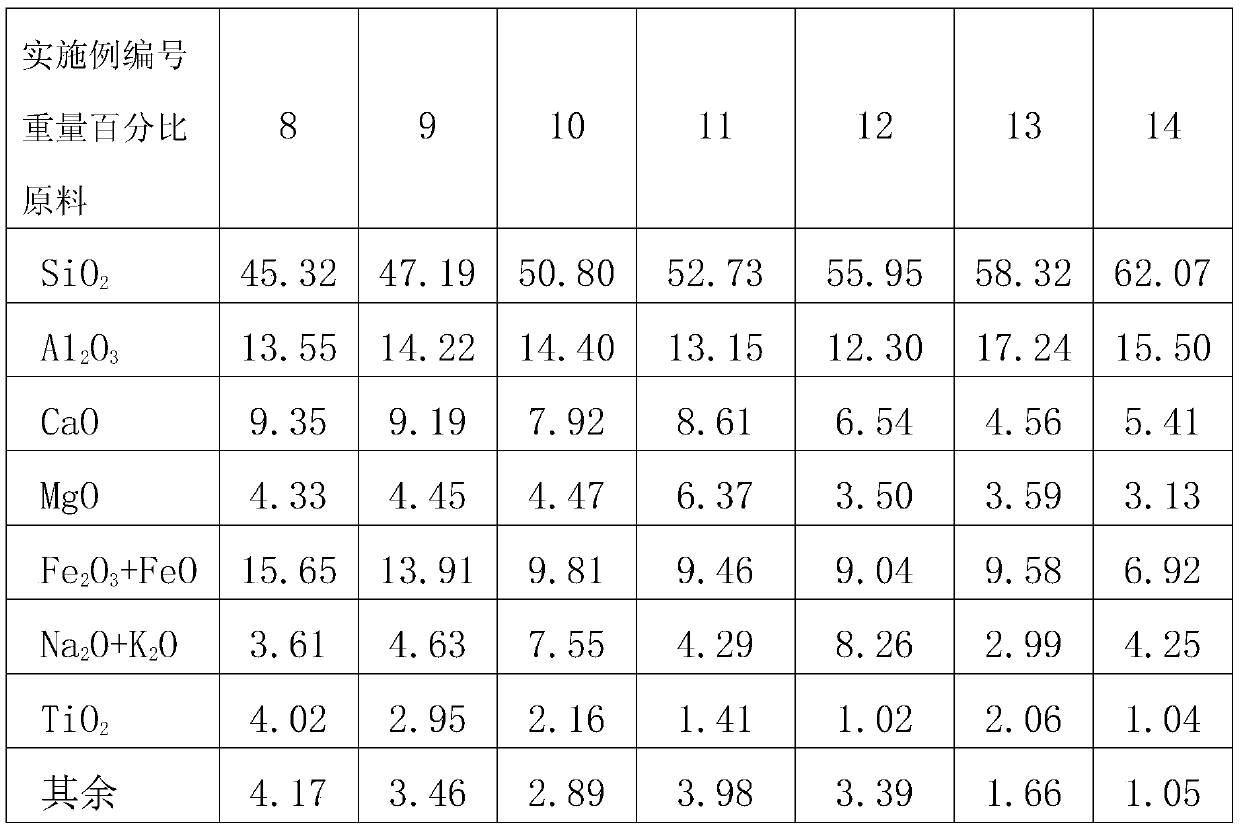

Examples

Embodiment 1

[0030]A radioactive waste solidification base material, the radioactive waste solidification base material is natural magmatic rock, the main chemical composition and weight percentage of the natural magmatic rock are: SiO 2 46.47%, A1 2 o 3 14.40%, CaO 8.81%, MgO 3.87%, Fe 2 o 3 +FeO 13.58%, Na 2 O 2.54%, K 2 O 1.75%, TiO 2 3.78%, the remaining 4.8% (can be a small amount of MnO, P 2 o 5 , SO 3 , BaO, SrO, ZrO 2 , CuO, ZnO, Nb 2 o 5 , Rb 2 O, Y 2 o 3 five or more compounds in the same group).

Embodiment 2

[0032] A method for preparing radioactive waste solidified base material, the steps are: crushing the natural basalt described in Example 1 with a jaw crusher, and then grinding it with a ball mill to obtain a radioactive waste solidified base material, the obtained radioactive waste The particle size of waste solidification base material is less than 200 mesh.

Embodiment 3

[0034] A glass solidified body (ZrO 2 A preparation method for simulating radioactive waste vitrified body), comprising the following steps:

[0035] a. Batching: radioactive waste immobilized base material obtained in Example 2, simulated radioactive waste ZrO 2 As a raw material, 26.4g of base materials, ZrO 2 The mass ratio of 3.6g is taken from each raw material;

[0036] b. Mixing: put each raw material into a ball mill and grind and mix evenly to obtain a mixed material;

[0037] c. Melting: melting the mixed material (which can be put into a crucible) at a temperature of 1450°C for 3 hours to obtain a melt;

[0038] d. Forming: pouring the melt into a copper mold preheated to a temperature of 800°C to form a molded object;

[0039] e. Annealing: heat the molding at 600°C for 1 hour, and then cool it to room temperature at a rate of 1°C / min to obtain the product-the glass solidified body of radioactive waste solidified base material (ie, ZrO 2 Simulated radioactive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com