Luminescence-enhanced rare earth doped phosphate full-white fluorescent powder and preparation method thereof

A phosphor, based phosphate technology, applied in luminescent materials, chemical instruments and methods, sustainable architecture, etc., can solve the problems of long synthesis cycle, unfavorable commercial production, and reduced luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

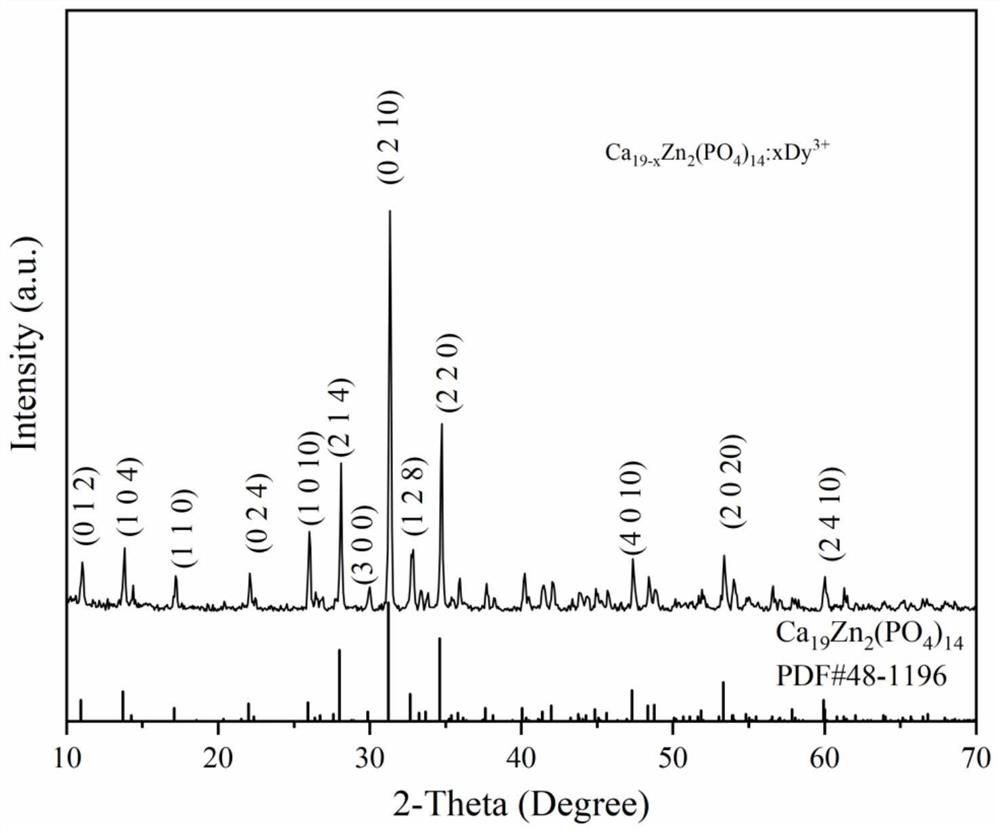

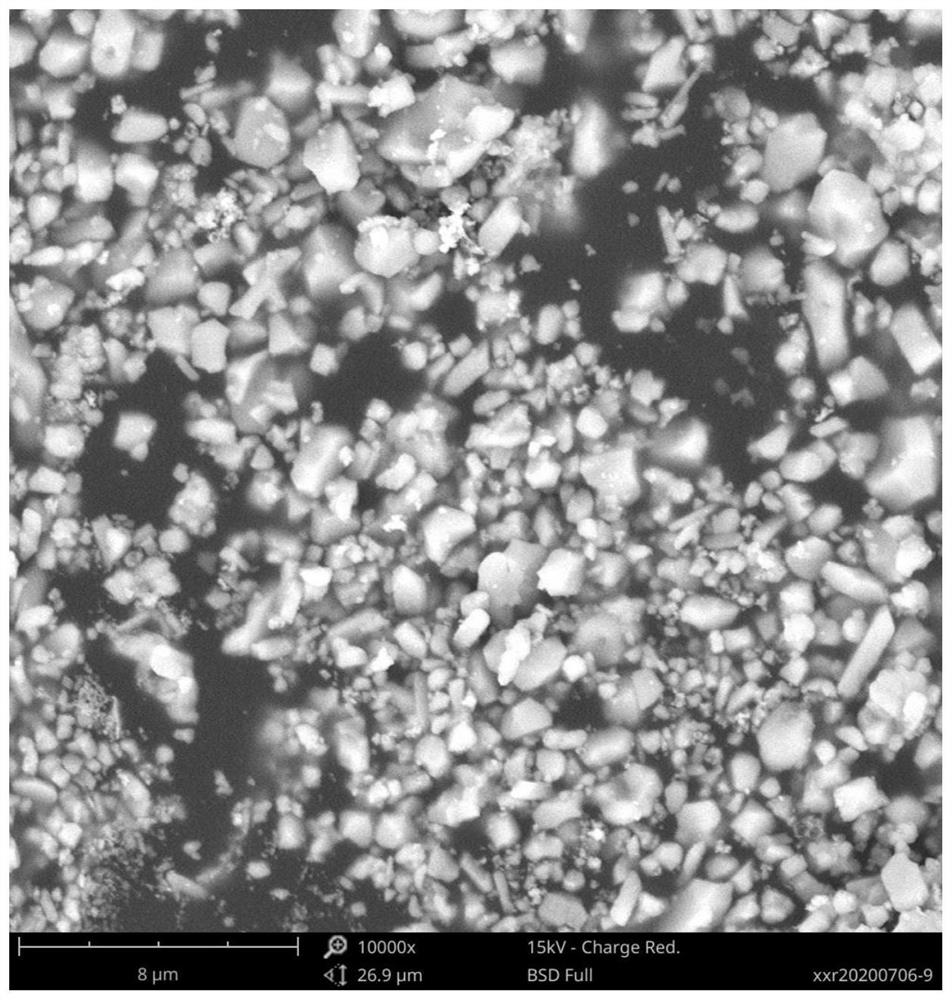

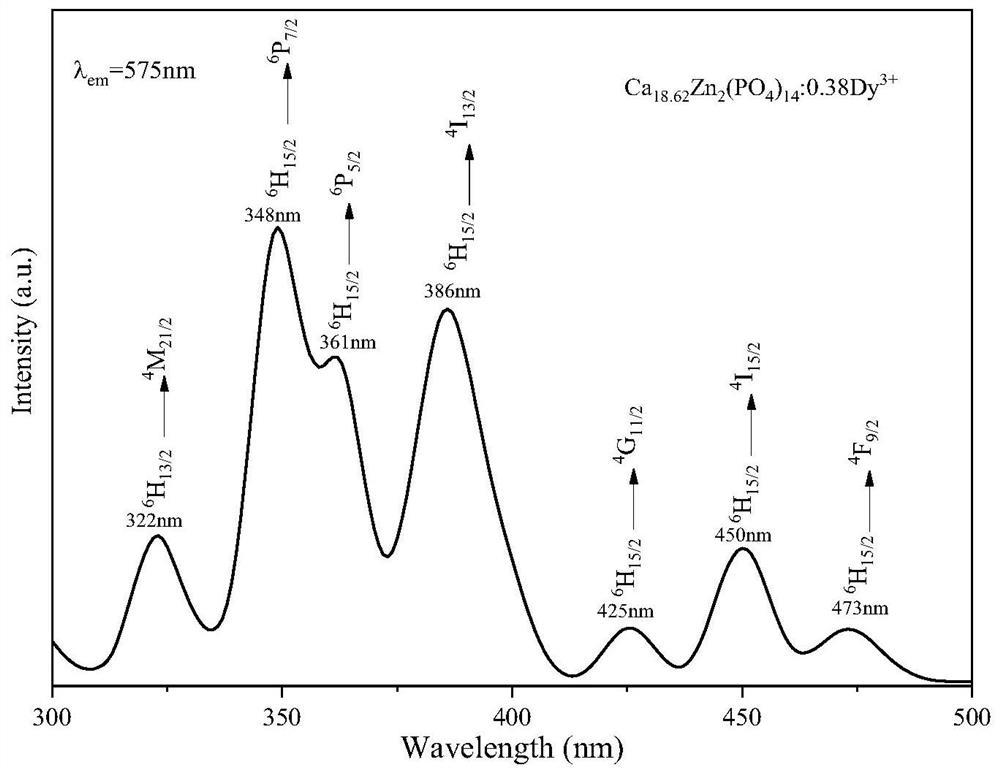

Embodiment 1

[0038] a) According to Ca 19-x Zn 2 (PO 4 ) 14-y (SiO 4 ) y :xDy 3+ (x=0.38, y=0) stoichiometric ratio weighs 4.3971g Ca (NO 3 ) 2 4H 2 O, 0.5949g Zn(NO 3 ) 2 ·6H 2 O, 0.1735g Dy(NO 3 ) 3 ·6H 2 O, 1.5759g NH 4 h 2 PO 4 and 8.0694g citric acid (C 6 h 8 o 7 ) was dissolved in deionized water and stirred until all raw materials were completely dissolved to form a solution, and the pH of the solution was adjusted to be 3;

[0039] b) heating the solution obtained in step a to 70° C., and continuously stirring at a speed of 800 rad / min until a sol is obtained;

[0040] c) Transfer the sol obtained in step b to a corundum crucible and keep it in a muffle furnace at 200°C for 0.5h. In this state, the moisture in the sol will disappear quickly, and the metal nitrate and citric acid will react to generate a flame; The temperature of the muffle furnace was raised to 800°C again at 5°C / min and kept for 1h. After the sample is cooled to room temperature with the furn...

Embodiment 2

[0043] a) According to Ca 19-x Zn 2 (PO 4 ) 14-y (SiO 4 ) y :xDy 3+ (x=0.38, y=0.3) stoichiometric ratio weighs 4.3971g Ca (NO 3 ) 2 4H 2 O, 0.5949g Zn(NO 3 ) 2 ·6H 2 O, 0.1735g Dy(NO 3 ) 3 ·6H 2 O, 1.5759g NH 4 h 2 PO 4 and 8.0694g citric acid (C 6 h 8 o 7 ) was dissolved in deionized water and stirred until all the raw materials were completely dissolved to form solution 1; weighed 0.0625g tetraethyl orthosilicate (C 8 h 20 o 4 Si) was dissolved in an ethanol solution to form a solution 2, and the solution 2 was slowly dropped into the solution 1, stirred and mixed evenly, and the pH value of the mixed solution was adjusted to 3;

[0044] b) heating the mixed solution obtained in step a to 70° C., and continuously stirring at a speed of 800 rad / min until a sol is obtained;

[0045] c) Transfer the sol obtained in step b to a corundum crucible and keep it in a muffle furnace at 200°C for 0.5h. In this state, the moisture in the sol will disappear quickl...

Embodiment 3

[0048] a) According to Ca 19-x Zn 2 (PO 4 ) 14-y (SiO 4 ) y :xDy 3+ (x=0.5, y=0.1) stoichiometric ratio weighs 4.3687gCa(NO 3 ) 2 4H 2 O, 0.5949g Zn(NO 3 ) 2 ·6H 2 O, 0.2283g Dy(NO 3 ) 3 ·6H 2 O, 1.5989g NH 4 h 2 PO 4 and 4.0347g citric acid solution (C 6 h 8 o 7 ) in deionized water until all raw materials are completely dissolved to form a solution 1; weigh 0.0208g tetraethyl orthosilicate (C 8 h 20 o 4 Si) was dissolved in an ethanol solution to form a solution 2, and the solution 2 was slowly dropped into the solution 1, stirred and mixed evenly, and the pH value of the mixed solution was adjusted to 5;

[0049] b) heating the mixed solution obtained in step a to 80° C., and continuously stirring at a speed of 500 rad / min until a sol is obtained;

[0050] c) Transfer the sol obtained in step b into a corundum crucible and keep it in a muffle furnace at 200°C for 0.5h. In this state, the moisture in the sol will disappear quickly, and the metal nitrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com