Dispersion-filled composite functional metal thermal-insulation layer

A composite function, thermal insulation layer technology, used in thermal insulation, nuclear power generation, pipeline protection, etc., can solve the problems of poor high temperature resistance and short service life, achieve stable chemical and physical properties, reduce radiation heat transfer and metal contact heat conduction The effect of heat transfer and improvement of thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

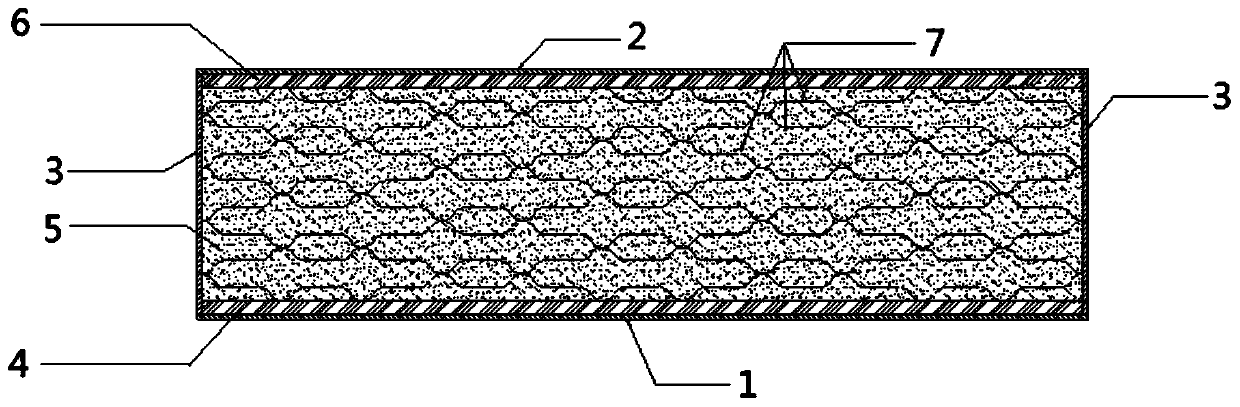

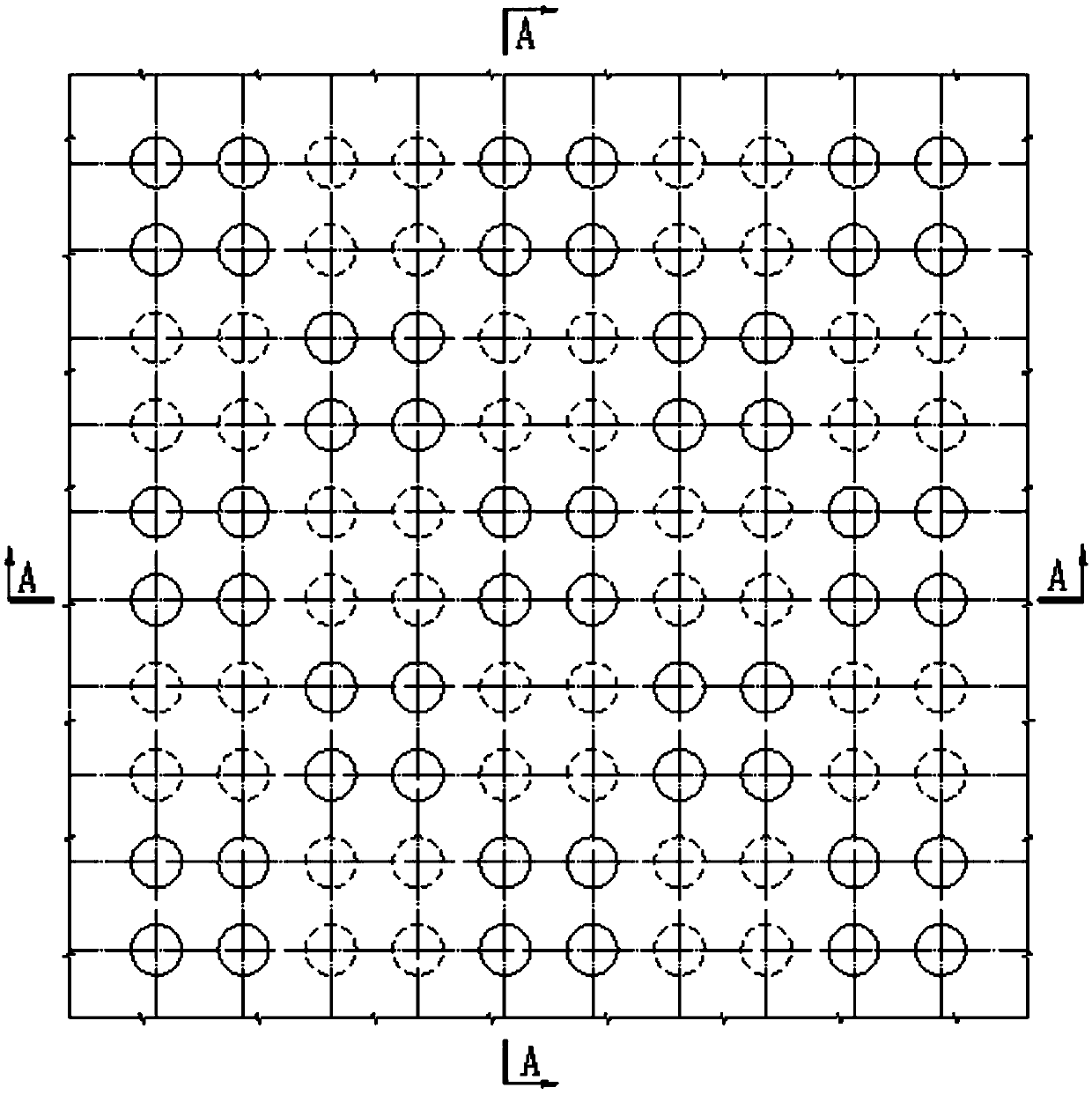

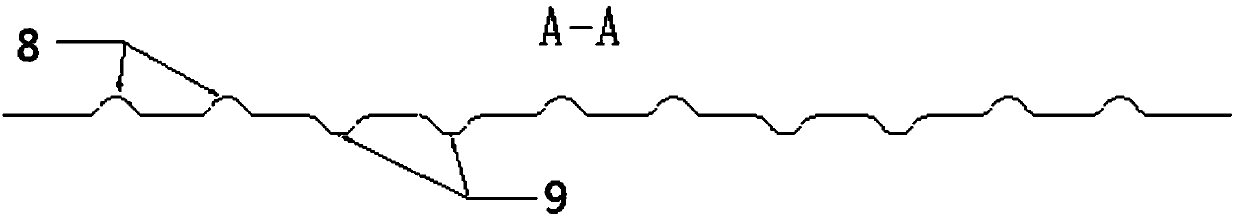

[0023] Such as figure 1 As shown, the composite metal insulation layer of the present invention is composed of an insulation outer box and an inner gamma shielding layer 4, an outer gamma shielding layer 6, boron carbide powder 5 and a metal reflective foil 7 packed inside the insulation outer box, The filling order of each part on the thickness section is as follows: the inner shell plate of the thermal insulation outer box 1, the inner gamma shielding layer 4, the multi-layer metal reflective foil 7, the boron carbide powder 5, the outer gamma shielding layer 6, the outer insulation layer The shell plate 2 of the box, wherein the boron carbide powder 5 is evenly dispersed in the cavity between two adjacent layers of metal reflective foils 7 . The overall shape of this kind of composite metal insulation layer with shielding function can be made into flat plate, circular tube, spherical shape according to the shape of the equipment surface. The high temperature range of its us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com