Method for measuring combination strength of investment casting shells

A bonding strength and investment casting technology, applied in the direction of applying stable shear force to test the strength of materials, preparation of test samples, etc., can solve the problem of high bonding force between shell layers, low normal temperature strength, and bonding strength Increase the difficulty and other issues to achieve the effect of lower requirements, simple test methods, and good inclusiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] Taking the determination of the interlayer bonding strength between the yttrium oxide surface layer and the bauxite transition layer of the shell commonly used in titanium alloy investment casting as an example.

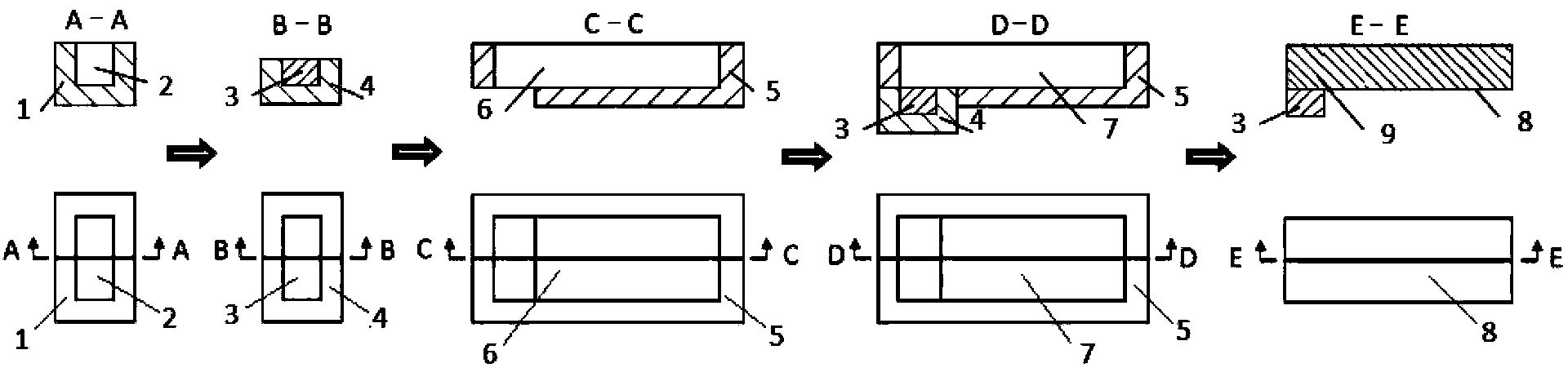

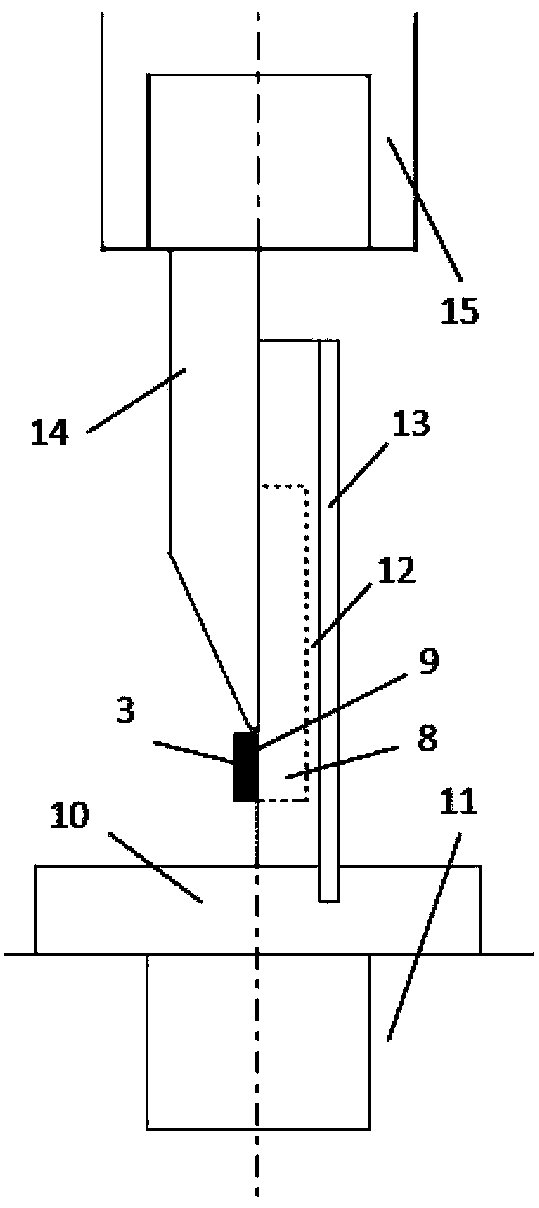

[0027] Such as figure 1 As shown, the yttrium oxide surface layer shell I3 is prepared layer by layer in the groove I2 of the wax mold I1 with a groove 2 of 20mm*10mm. The viscosity and sanding particle size of the slurry are consistent with the actual production situation, and the drying temperature is 20°C , drying time 24h. After preparing the three layers, the total thickness of the shell I3 is about 2.5 mm, and the part of the upper part of the groove that is not filled by the shell I3 is polished to form the polished wax mold I4 with the yttrium oxide shell, so that the polished belt The groove depth of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com