Configuration optimization method of shuttle-carrier warehousing system

A storage system, configuration optimization technology, applied in storage devices, conveyor control devices, conveyor objects, etc., can solve problems such as lack of flexibility, high equipment loss rate, lack of research, etc., to reduce risks, distribute evenly, and distribute Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] The present invention provides a configuration optimization method of a mother-child shuttle vehicle intensive storage system, the specific steps are as follows:

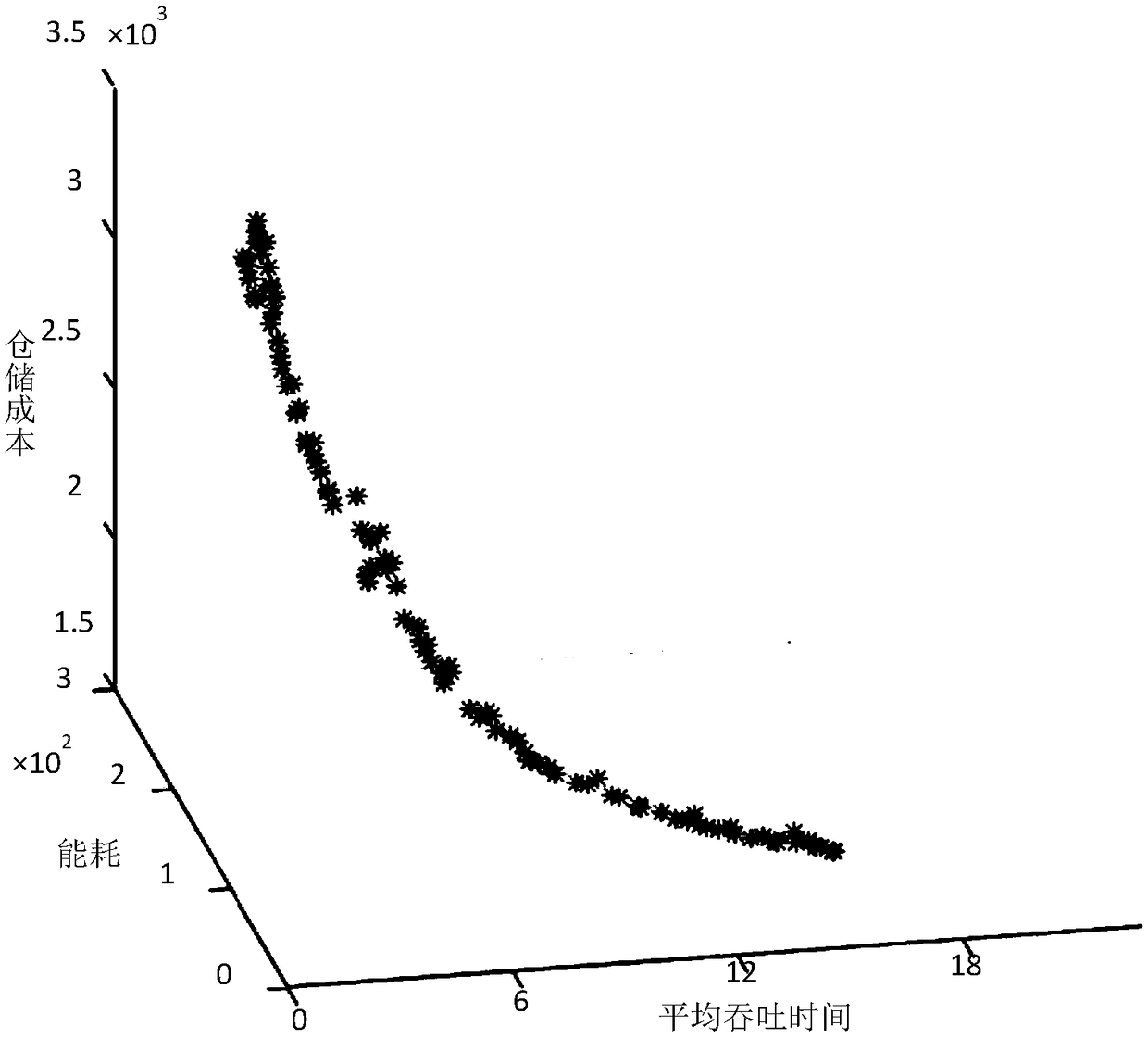

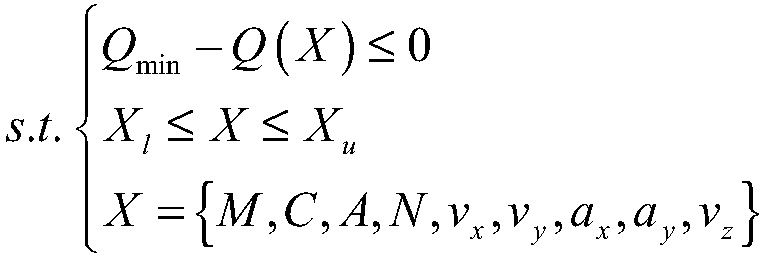

[0033] Step 1. Construct an optimization model for the configuration of the mother-child shuttle-type intensive storage system

[0034] 1.1 Carry out analysis and research on the mother-son-child shuttle-type intensive storage system, determine the decision variables and optimization goals.

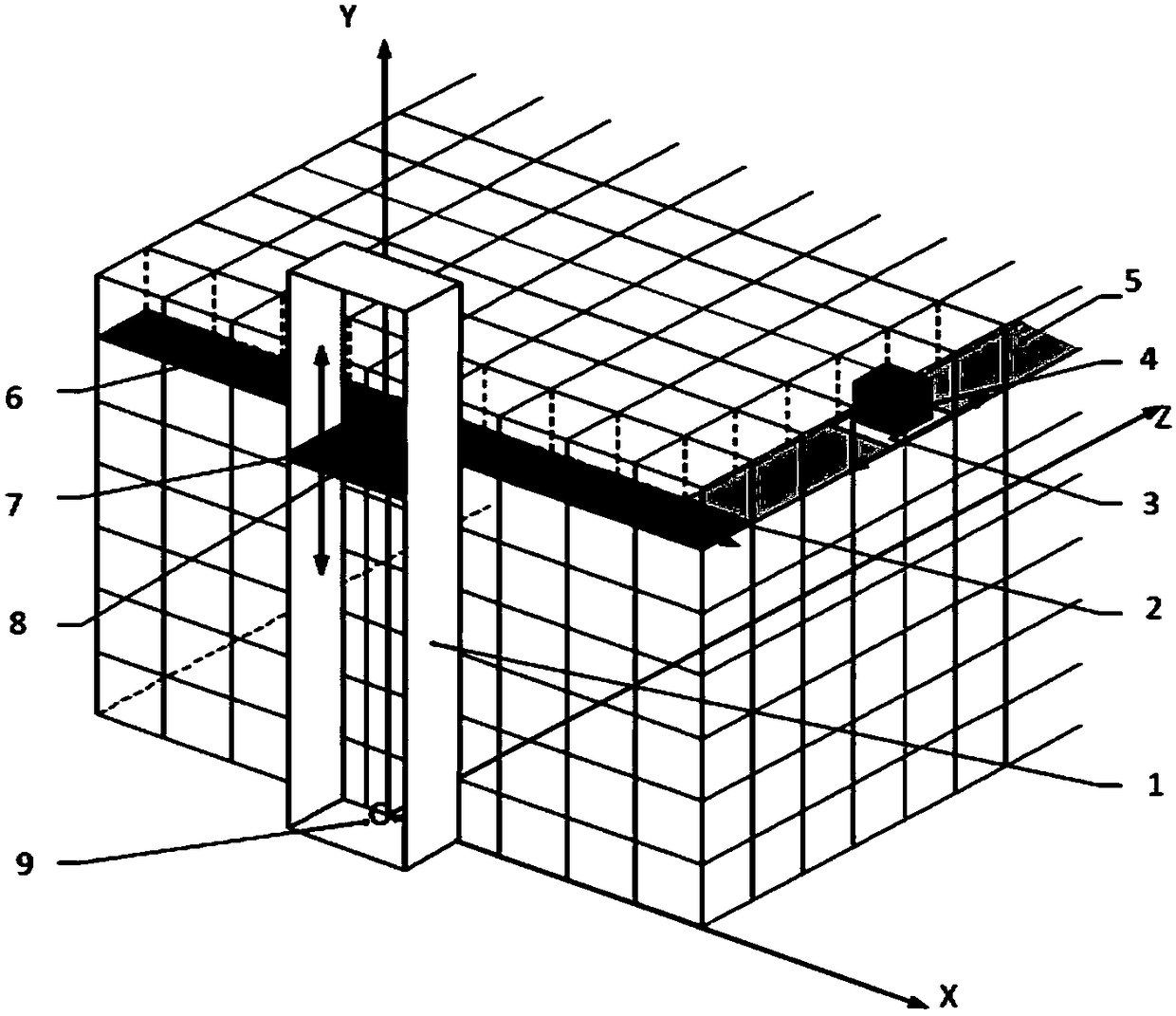

[0035] see figure 1 , the intensive storage system of the mother-child shuttle vehicle is transformed into a model under the OXYZ coordinate system. The dense storage system of the mother-child shuttle vehicle includes a plurality of unit shelves that can perform out / in warehouse operations at the same time, and the unit shelf system based on the unit shelf Including several layers of shelves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com