Method for preparing light-cured electromagnetic shielding composite material based on multi-arm carbon nanotube

A technology of multi-arm carbon nanotubes and electromagnetic shielding, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of poor electromagnetic shielding performance, achieve strong absorption capacity, strong attenuation of electromagnetic wave energy, and reduce skin depth effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Embodiments of the present invention provide a method for preparing a light-cured electromagnetic shielding composite material based on multi-armed carbon nanotubes, including:

[0031] Uniformly disperse carbon nanotubes in tetrahydrofuran;

[0032] Add methyl vinyl silicone resin and silicone resin curing agent to the dispersed carbon nanotubes, and then stir at a speed of 800-1000 rpm until the methyl vinyl silicone resin is completely dissolved in tetrahydrofuran to obtain a mixed solution;

[0033] Ultrasonic vibration is performed on the mixed solution, and then evaporated at a temperature of 65-75°C until the tetrahydrofuran is completely evaporated to obtain a precipitate;

[0034] Dry the sediment;

[0035] The dried precipitate is molded and vulcanized for 30-40 minutes under a pressure of 11-13 MPa and a temperature of 140-160° C. to finally obtain a light-cured electromagnetic shielding composite material.

[0036] The light-cured electromagnetic shielding...

Embodiment 1

[0039] A method for preparing a light-cured electromagnetic shielding composite material based on multi-armed carbon nanotubes, comprising:

[0040] Under the ultrasonic power of 350-400W, the carbon nanotubes are uniformly dispersed in tetrahydrofuran by means of ultrasonic vibration, wherein the outer diameter of the multi-walled carbon nanotubes is 17-20nm;

[0041] Add methyl vinyl silicone resin and silicone resin curing agent to the dispersed carbon nanotubes, wherein the molecular weight of the methyl vinyl silicone resin is 450000-550000 g / mol, and the silicone resin curing agent is 2,3 , 5-two (t-butyl peroxide)-2,5-dimethylhexane, the weight of the silicone resin curing agent is 2.5% of the weight of the methyl vinyl silicone resin, and ensure that the carbon The addition amount of nanotubes is 6wt.% of the total weight of the carbon nanotubes, the methyl vinyl silicone resin, and the silicone resin curing agent, and then stir at a speed of 900rpm until the methyl vi...

Embodiment 2

[0047] A method for preparing a light-cured electromagnetic shielding composite material based on multi-armed carbon nanotubes, comprising:

[0048] Under the ultrasonic power of 350-390W, the carbon nanotubes are uniformly dispersed in tetrahydrofuran by means of ultrasonic oscillation, wherein the outer diameter of the multi-walled carbon nanotubes is 15-22nm;

[0049] Add methyl vinyl silicone resin and silicone resin curing agent to the dispersed carbon nanotubes, wherein the molecular weight of the methyl vinyl silicone resin is 480,000 to 600,000 g / mol, and the silicone resin curing agent is 2,3 , 5-two (t-butyl peroxide)-2,5-dimethylhexane, the weight of the silicone resin curing agent is 2% of the weight of the methyl vinyl silicone resin, and ensure that the carbon The addition of nanotubes is 5wt.% of the total weight of the carbon nanotubes, the methyl vinyl silicone resin, and the silicone resin curing agent, and then stir at a speed of 800 rpm until the methyl vin...

PUM

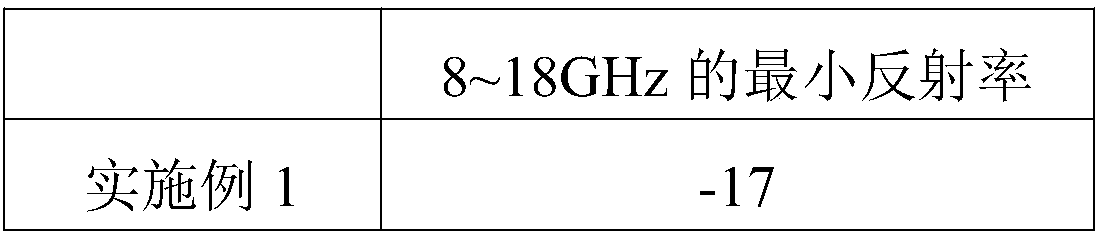

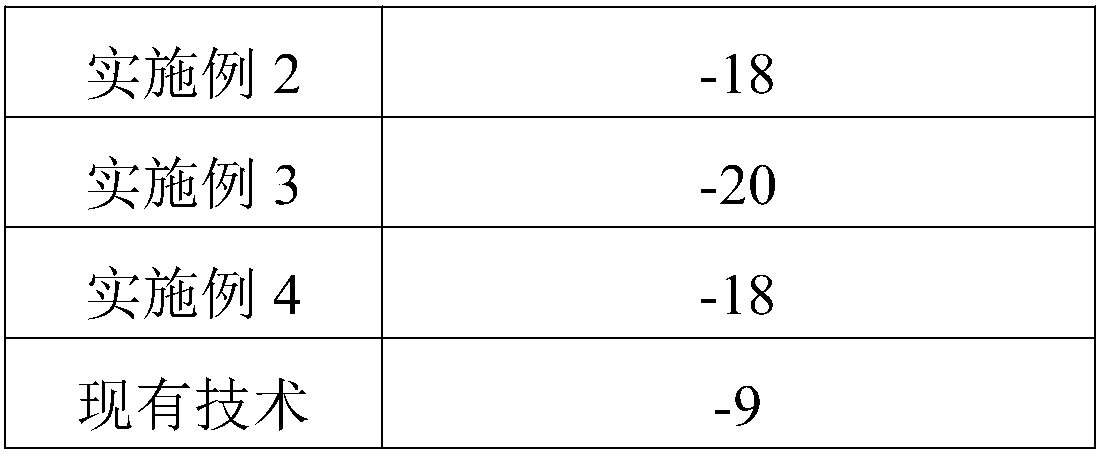

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com