Wire of 3D printing polylactic acid/conductive filler electromagnetic shielding composite material, preparation method and application

A conductive filler and 3D printing technology, applied in the fields of magnetic field/electric field shielding, conductive/antistatic filament manufacturing, single-component polyester artificial filament, etc., can solve poor electromagnetic shielding performance, poor electromagnetic shielding performance, carbon Uniform dispersion of nanotubes and other issues to achieve the effect of ensuring electromagnetic shielding performance and solving poor electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

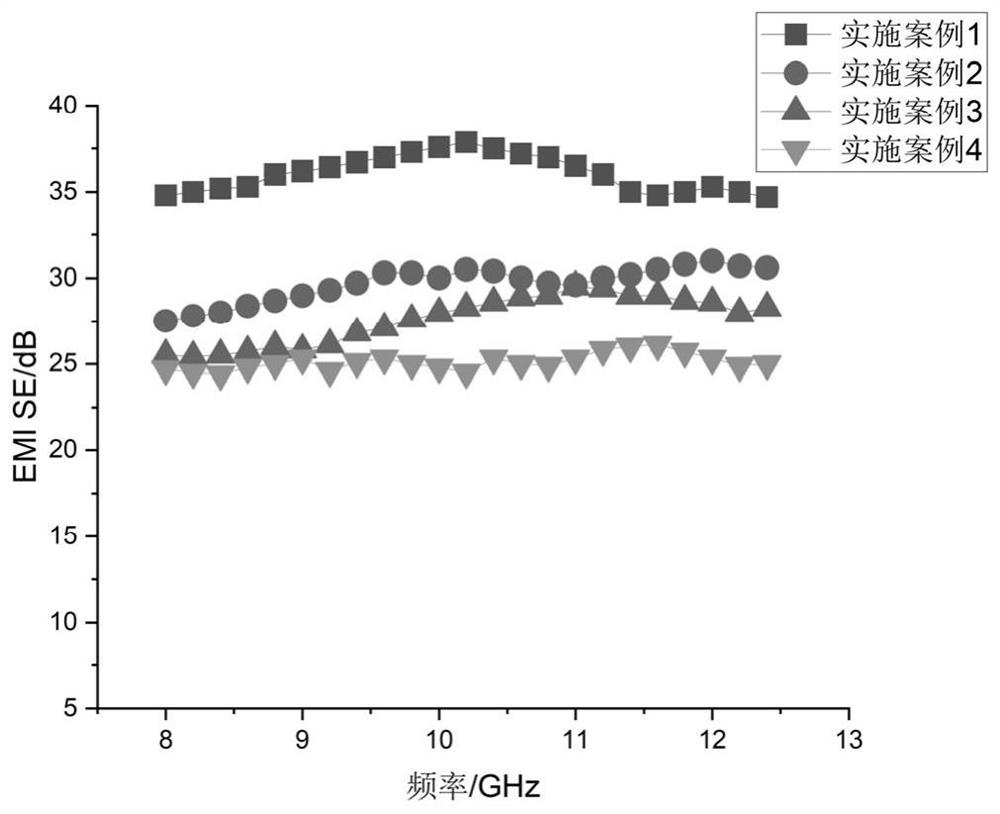

Embodiment example 1

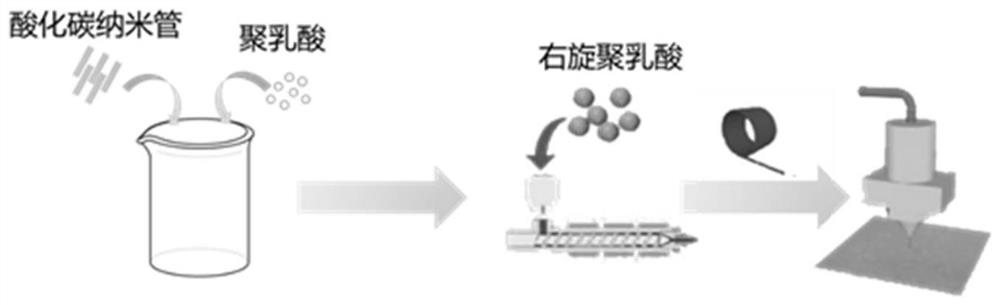

[0033] Example 1: Preparation of 3D printed polylactic acid / conductive filler electromagnetic shielding composites

[0034] The electromagnetic shielding composite material is made from the following raw materials by weight: 0.5 parts of carbon nanotubes, 300 parts of a mixture of concentrated sulfuric acid and concentrated nitric acid (the mass of concentrated sulfuric acid and concentrated nitric acid is 3:1), 80 parts of polylactic acid, and dextrorotatory polylactic acid. 20 servings of lactic acid.

[0035] The specific implementation steps are as follows:

[0036] Step 1: take carbon nanotubes, add a mixture of concentrated sulfuric acid and concentrated nitric acid for activation, and prepare acidified carbon nanotubes, which are for subsequent use, wherein the carbon nanotubes are 0.5 parts by weight, and the mixture of concentrated sulfuric acid and concentrated nitric acid is 300 parts by weight. (The mass ratio is 3:1), the activation temperature of the acidified c...

Embodiment example 2

[0043] Implementation Case 2: Preparation of 3D Printing Polylactic Acid / Conductive Filler Electromagnetic Shielding Composites

[0044] The specific preparation method is as in Embodiment 1; the parts by weight of the mixture of concentrated sulfuric acid and concentrated nitric acid in Step 1 of Example 1 are changed to 350 parts, and the mass ratio thereof is changed to 3:2, and the remaining steps are unchanged to obtain Embodiment 2.

Embodiment example 3

[0045] Implementation Case 3: Preparation of 3D Printing Polylactic Acid / Conductive Filler Electromagnetic Shielding Composites

[0046] The specific implementation method is as in Embodiment 1; the parts by weight of polylactic acid in step 3 are changed to 120 parts, and the remaining steps remain unchanged to obtain Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com