A kind of modified graphene/thermosetting resin composite material and preparation method thereof

A resin composite material and graphene technology, which is applied in the field of modified graphene/thermosetting resin composite materials and their preparation, can solve the problems of decreased processing performance and high dielectric constant of composite materials, and achieves improved dielectric constant and high dielectric constant. Electric constant, the effect of excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of hydrochloric acid-doped polyaniline-modified carbon nanotubes

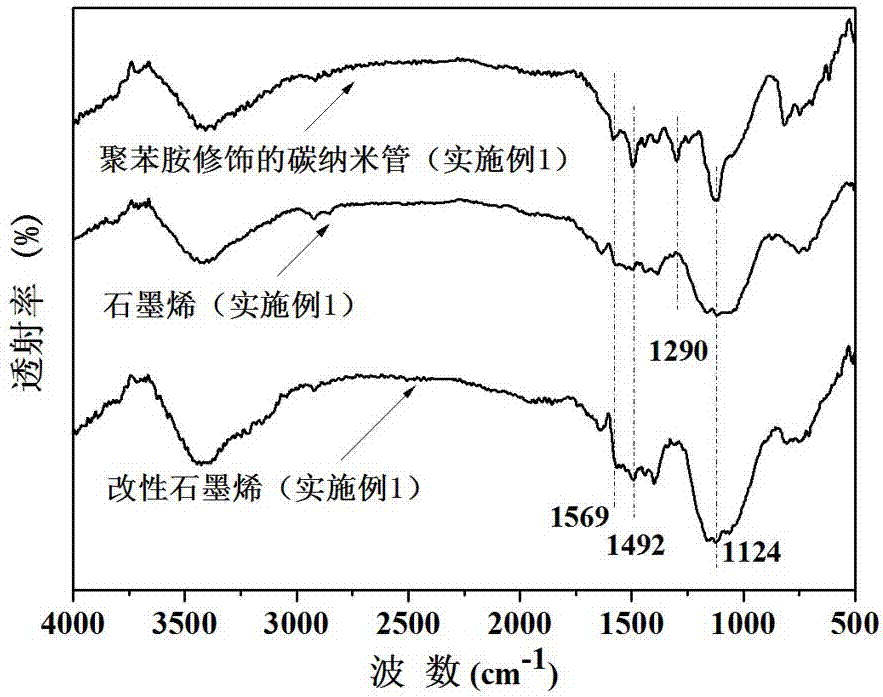

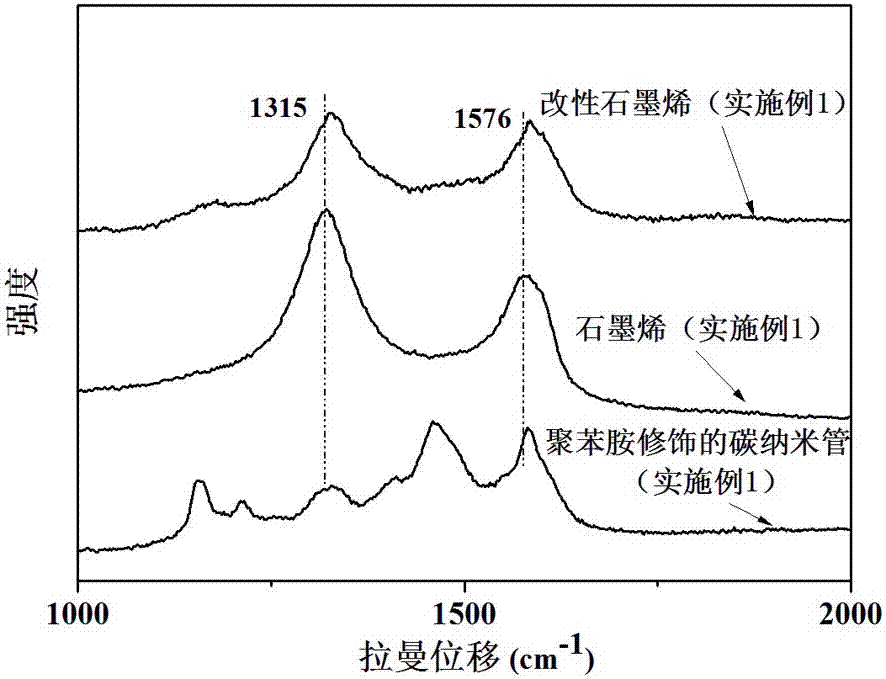

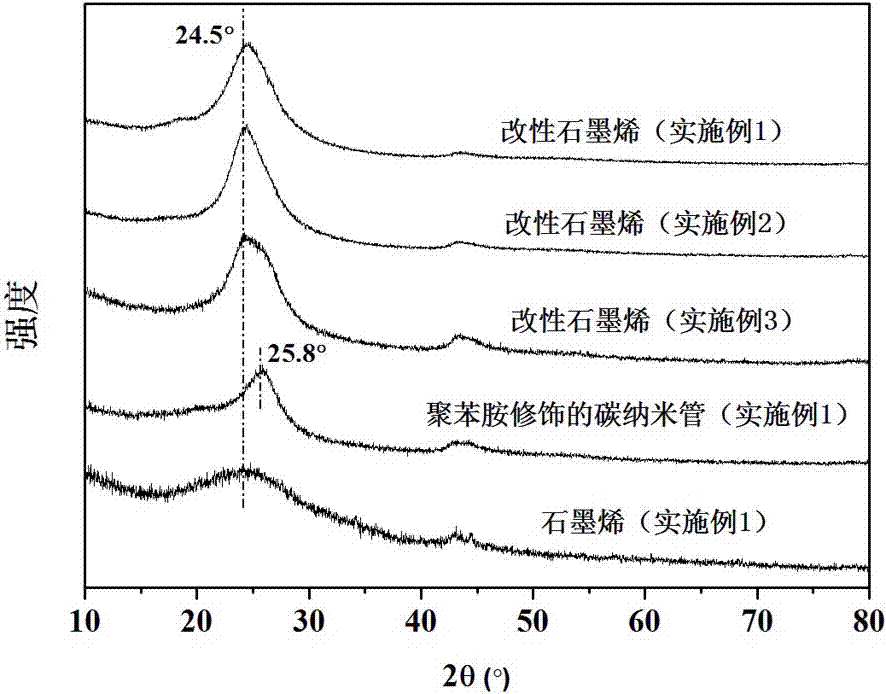

[0029] in N 2 Under protection, at 0-5°C, disperse 1g of multi-walled carbon nanotubes into 500mL of deionized water, add 0.99g of sodium dodecyl sulfate, and mix for 0.5h under stirring; then add 0.4g of aniline, and Add 100mL hydrochloric acid solution (0.043mol / L), and mix well under stirring conditions for 1h; slowly add 100mL ammonium persulfate solution (0.043mol / L) dropwise, after the dropwise addition, react for 6h, after the reaction, filter and wash , and dry to obtain polyaniline-modified carbon nanotubes. The infrared spectrogram, Raman spectrogram, X-ray diffraction pattern, scanning electron microscope pattern and electrical conductivity at 1 Hz of the prepared hydrochloric acid-doped polyaniline-modified carbon nanotubes are shown in the appendix respectively. figure 1 , 2 , 3, 4 and 5.

Embodiment 2

[0041] 1. Preparation of modified graphene

[0042] Weigh 1 g of graphite oxide (provided in Example 1) and disperse it in 500 mL of deionized water, stir and sonicate for 1 hour to obtain a graphene oxide dispersion, add 0.50 g of hydrochloric acid doped polyaniline-modified carbon nanotubes (provided in Example 1) Put it into the graphene oxide dispersion, stir it ultrasonically, react at 60°C for 12h, then add 10g of L-ascorbic acid, raise the temperature of the reaction liquid to 80°C and react for 24h, soak in 500mL of 1mol / L ammonia water for 1h, After suction filtration, washing, and drying, a graphene-hydrochloric acid-doped polyaniline-modified carbon nanotube composite is obtained, wherein the mass of the hydrochloric acid-doped polyaniline-modified carbon nanotube is twice the mass of graphene. The X-ray diffraction figure of prepared graphene-modified graphene, the electrical conductivity under the scanning electron microscope picture, 1Hz are shown in the attached...

Embodiment 3

[0046] 1. Preparation of modified graphene

[0047] Weigh 1 g of graphite oxide (provided in Example 1) and disperse it in 500 mL of deionized water, stir and sonicate for 1 h to obtain a graphene oxide dispersion, add 1.0 g of hydrochloric acid-doped polyaniline-modified carbon nanotubes (Example 1) to In the graphene oxide dispersion, ultrasonically stirred, reacted at 60°C for 12h, then added 10g of L-ascorbic acid, raised the temperature of the reaction liquid to 80°C and reacted for 24h, soaked in 500mL of 1mol / L ammonia water for 1h, pumped After filtering, washing and drying, the modified graphene is obtained, wherein the quality of the hydrochloric acid-doped polyaniline-modified carbon nanotubes is twice that of the graphene. The X-ray diffraction pattern of prepared modified graphene, the scanning electron microscope pattern, the electrical conductivity under 1Hz are respectively shown in the appendix image 3 , 4 and 5.

[0048] 2. Preparation of modified graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com