A road engineering pavement repair device

A pavement repair and road engineering technology, applied in the direction of road repair, roads, roads, etc., can solve the problems of restrictions, affect the safety of vehicles, uneven unevenness, improve service life, improve repair efficiency, and increase adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0047] As an embodiment of the present invention, an activated carbon layer 143 is provided on the inner wall of the filling chamber 14 . The asphalt concrete mixture has an unpleasant smell, which is harmful to the human body. By providing an activated carbon layer 143 in the filler chamber 14, the activated carbon layer 143 absorbs the odor in the asphalt concrete mixture, thereby preventing the odor from causing harm to the human body. hazards, thereby improving the efficiency of pavement repair.

[0048] As an embodiment of the present invention, the filler chambers 14 are distributed at both ends of the locomotive 1 . The two ends of the locomotive 1 are provided with filler chambers 14 to maintain the balance of the locomotive 1, thereby improving the safety of the locomotive 1 in operation.

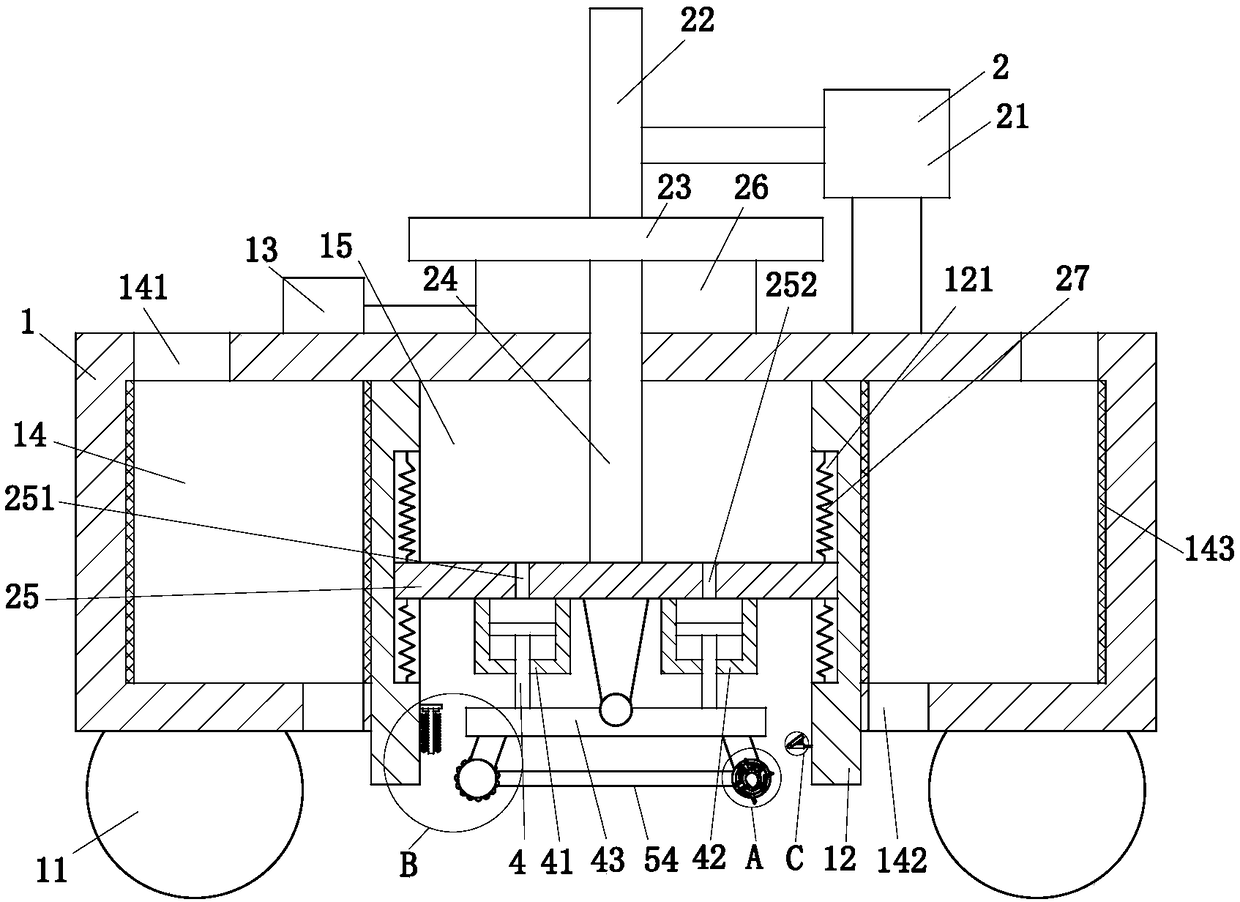

[0049] During work, the locomotive 1 is driven to the road surface that needs to be repaired, the drive motor 21 is driven, the cam 22 squeezes the No. 1 disk 23, and the No. 1 ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com