Diesel engine fuel filter and processing technique thereof

A technology of fuel filter and processing technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc. It can solve the problems of filter paper deformation, poor integrity, and unstable connection and fixation, so as to achieve convenient disassembly and installation and improve the structure Strength, fixed and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

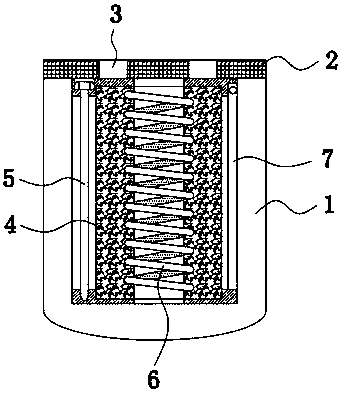

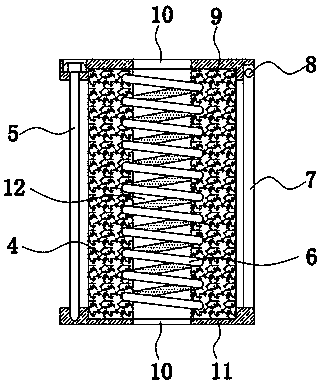

[0023] The present invention provides such Figure 1-2 A fuel filter for diesel engines, including a protective shell 1, a filter body is provided in the middle of the inner cavity of the protective shell 1, and a sealing end cap 2 is installed on the top of the upper end of the protective shell 1, and the sealing end cap 2 is provided with an oil inlet hole 3, and the filter body includes an upper end cover 9, a lower end cover 11 and a filter paper 4, and the filter paper 4 is fixed between the upper end cover 9 and the lower end cover 11, and the lower end cover 11 The right side of the upper end is provided with a vertical plate 7, the upper part of the vertical plate 7 is movably connected to the right end of the upper end cover 9 through a pin shaft 8, and the left end of the upper end cover 9 is connected to the left side of the upper end of the lower end cover 11 through a countersunk head screw 5 , The interior of the filter paper 4 is provided with spiral reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com