A filter device for pipeline transportation in water conservancy projects

A technology for water conservancy projects and filtration devices, applied in filtration and separation, membrane filters, fixed filter element filters, etc., can solve the problems of time-consuming, labor-intensive, poor filtration effect, and high maintenance costs, and achieve convenient and fast operation, improve service life, Reduce the effect of direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

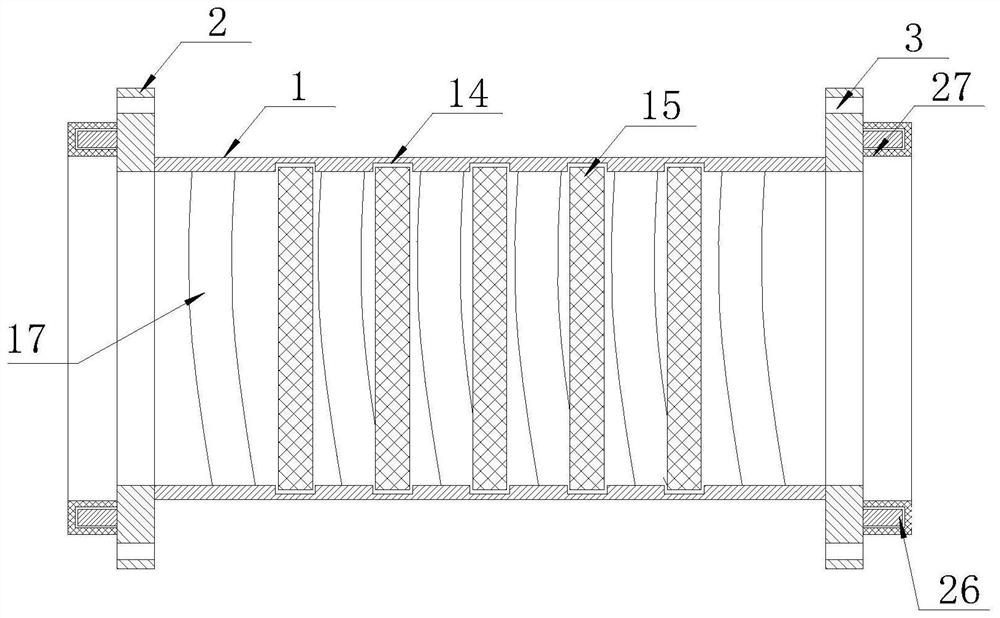

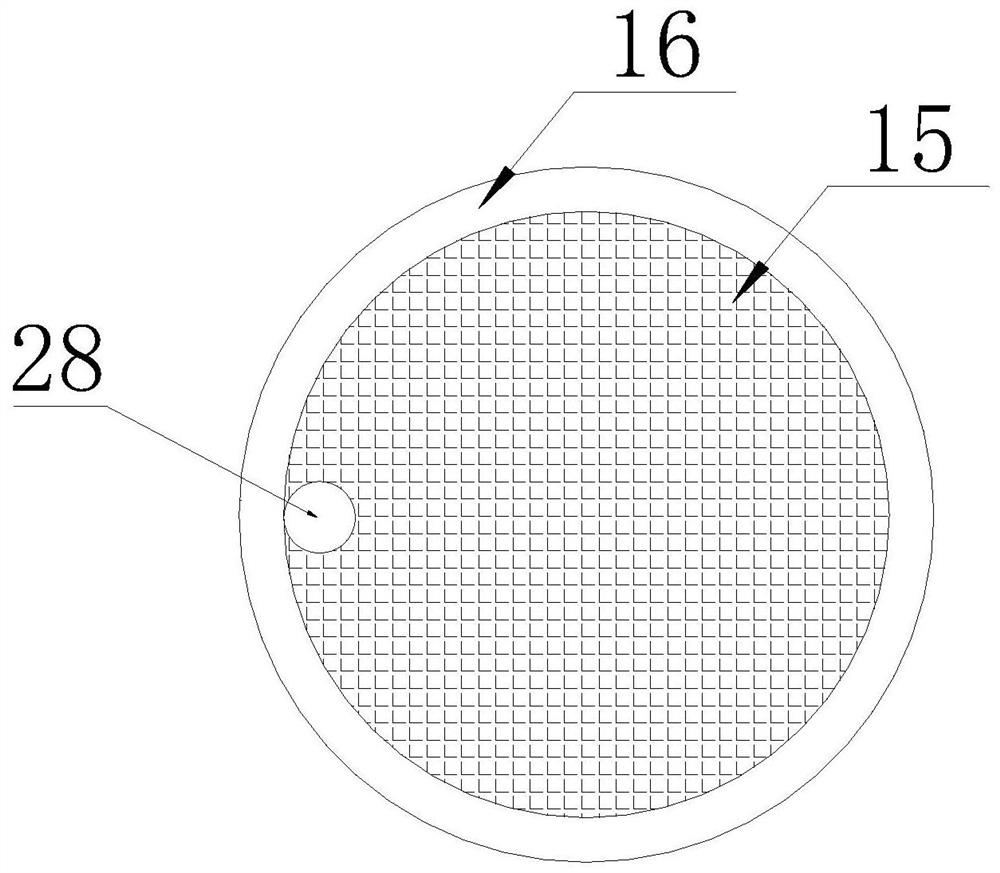

[0032] The present invention provides a filter device for pipeline transportation in water conservancy projects, comprising a filter cavity 1, connecting flanges 2 are arranged at both ends of the filter cavity 1, and positioning Connecting pin holes 3, the filter cavity 1 includes a top cover 101 and a bottom cover 102, both ends of the top cover 101 are fitted with the inner side walls of the connecting flange 2 on the corresponding side, and the two ends of the bottom cover 102 All are fixedly connected with the inner side wall of the connecting flange 2 on the corresponding side, and the inside of the filter chamber 1 is provided with an annular fitting groove 14, and a filter plate 15 is fitted in the annular fitting groove 14, and the edge of the filter plate 15 The position is covered with a sealing rubber ring 16, the inner wall of the filter cavity 1 is provided with a diversion groove 17, the inner side of one end of the bottom cover 102 is provided with a groove 18 a...

Embodiment 2

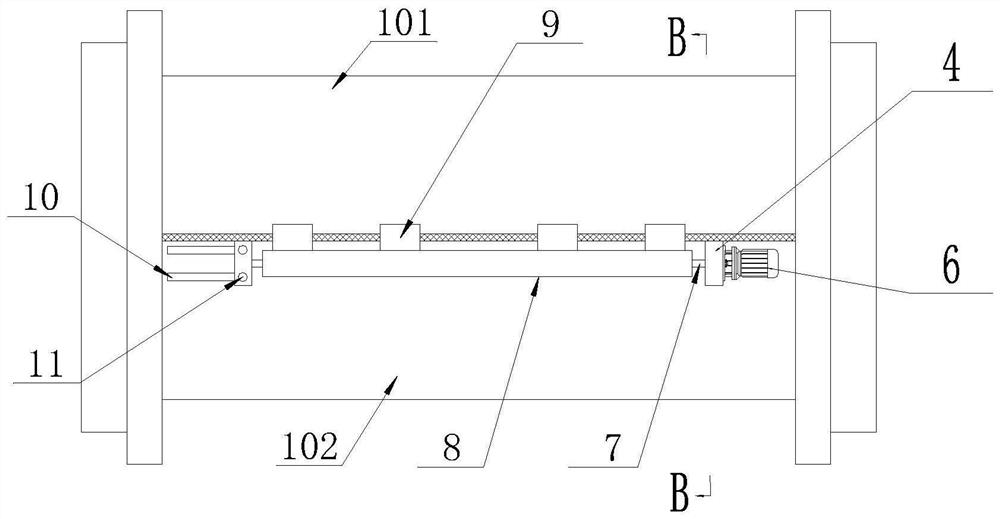

[0038] Further, in the technical solution of Example 1, a slide groove 10 is provided on one end surface of the bottom cover 102, and a threaded hole is provided at the bottom end of the slide groove 10, and the bottom end of one of the first fixing blocks 4 is arranged on In the chute 10, and movably connected with the chute 10, the top of one of the first fixed blocks 4 is provided with a first locking screw hole 11, and the first locking screw hole 11 matches the threaded hole , the outer fixed sleeve of the rotating shaft 7 is provided with a transmission gear 12, the inner wall of the sleeve 8 is equipped with gear teeth 13, the transmission gear 12 is meshed with the gear teeth 13, and both ends of the sleeve 8 are connected to the opposite side. The inner wall of the first fixed block 4 of the filter cavity 1 is attached to the inner wall. When the top cover 101 or the bottom cover 102 of the filter chamber 1 is partially damaged, the connecting flange 2 on the side away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com