Chemical sewage filtering device

A technology for filtering device and chemical sewage, applied in the fields of filtration and separation, filtration loop, chemical instruments and methods, etc., can solve problems such as equipment not working normally, sewage pipe blockage, water pollution, etc., so as to improve the filtration performance of filter element and ensure normal Use, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

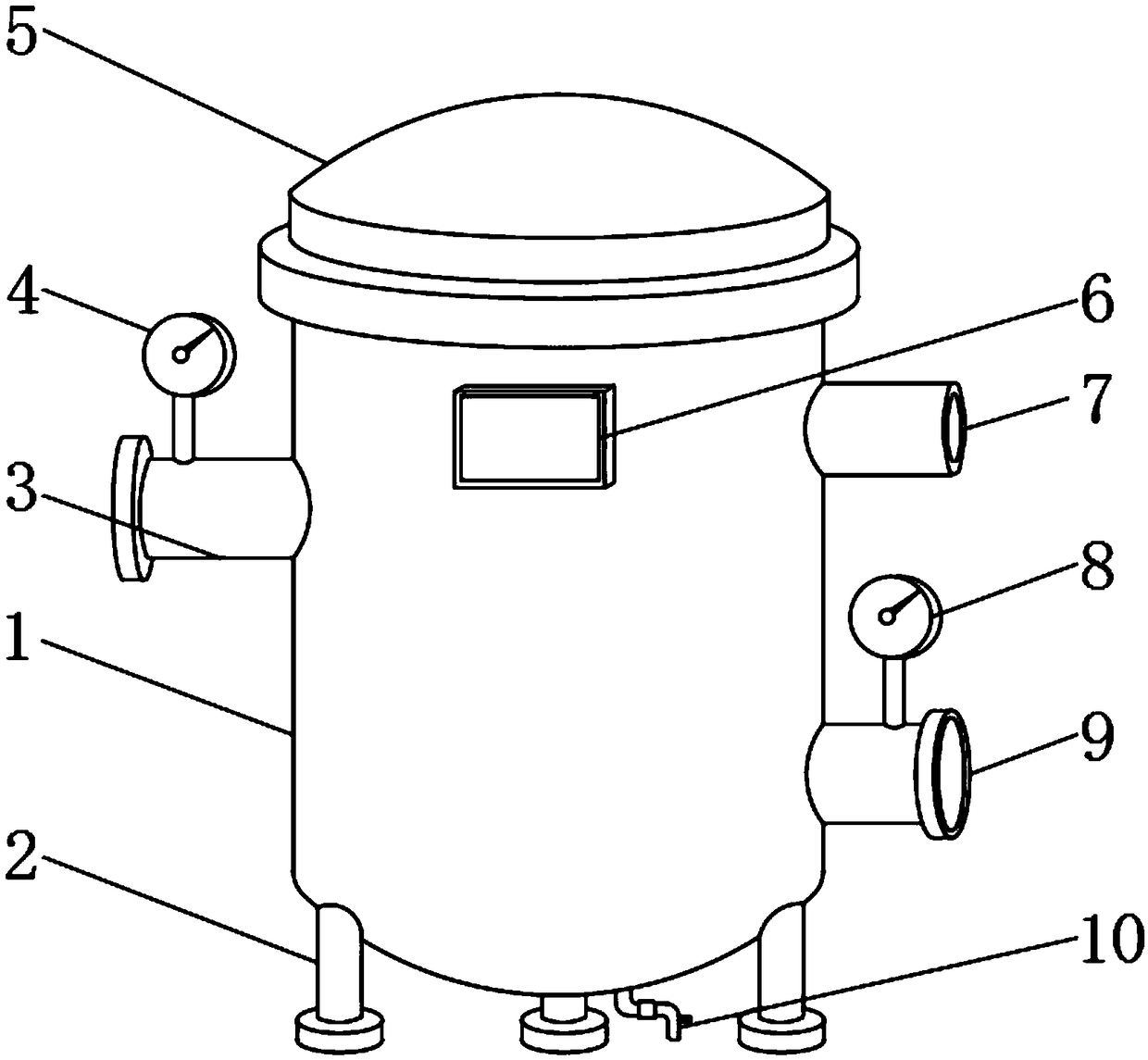

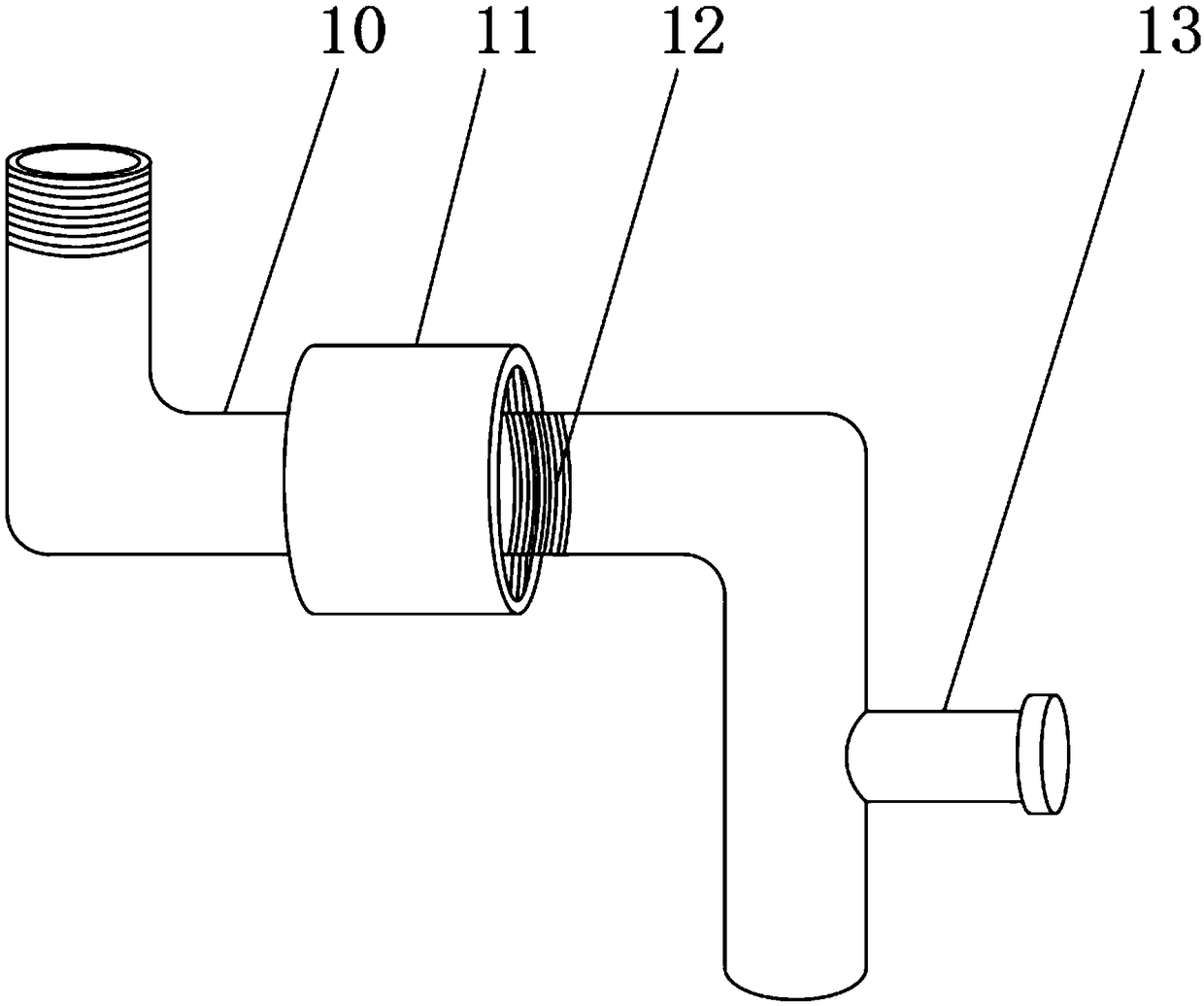

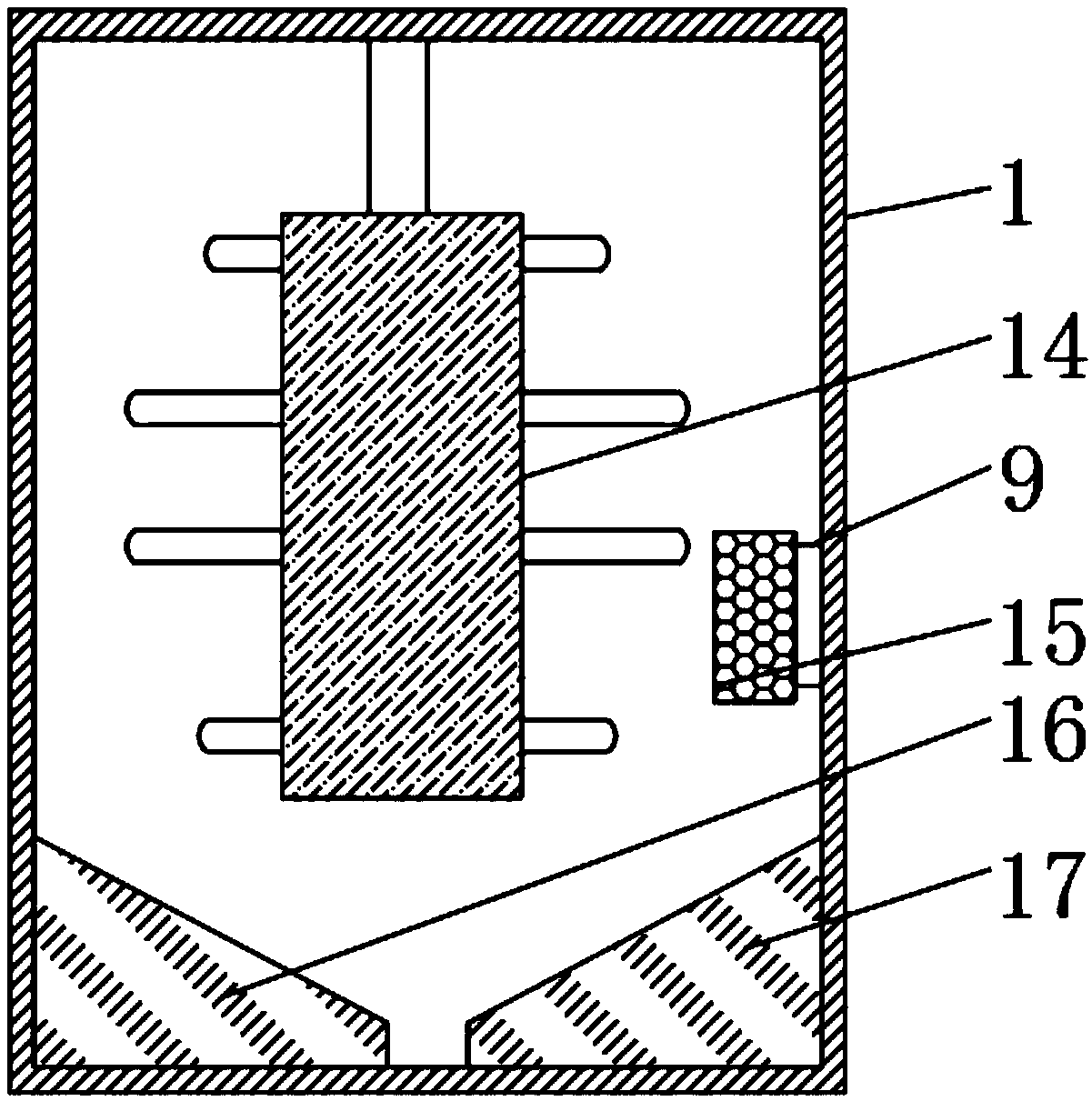

[0022] The first embodiment: see Figure 1-3 As shown, the present invention provides a chemical sewage filtering device, comprising: a support mechanism, the support mechanism includes a sewage filter barrel 1 and a sewage inlet pipe 3, the upper end of the sewage filter barrel 1 is provided with a bucket cover 5, the The lower end of the sewage filter bucket 1 is provided with a detachable sewage pipe 10 and three sets of brackets 2, and a casing 11 is movably installed on the detachable sewage pipe 10, and the position of the detachable sewage pipe 10 close to the casing 11 is provided with a screw thread Circle 12, and a valve 13 is movably installed near the lower end of the detachable sewage pipe 10, and a backwash water pipe 7 is fixedly installed near the upper end of the sewage filter bucket 1, and the sewage filter bucket 1 is located below the backwash water pipe 7 A clean water discharge pipe 9 is arranged at the position of the clean water discharge pipe 9, and a ...

no. 2 approach

[0026]The second embodiment: a chemical sewage filter device, including: a support mechanism, the support mechanism includes a sewage filter barrel 1 and a sewage inlet pipe 3, the upper end of the sewage filter barrel 1 is provided with a barrel cover 5, and the sewage filter The lower end of the barrel 1 is provided with a detachable sewage pipe 10 and three sets of brackets 2, and a sleeve 11 is movably installed on the detachable sewage pipe 10, and a threaded ring 12 is provided at a position close to the sleeve 11 of the detachable sewage pipe 10. , and a valve 13 is movably installed near the lower end of the detachable sewage pipe 10, and a backwash water pipe 7 is fixedly installed near the upper end of the sewage filter bucket 1, and the sewage filter bucket 1 is located below the backwash water pipe 7 A clean water discharge pipe 9 is arranged at the clean water discharge pipe 9, and a No. 2 flow meter 8 is arranged on the clean water discharge pipe 9; the sewage inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com