Glass kiln gas denitration spray ammonia injection grid online ash removing device and ash removing method thereof

A technology for ammonia spraying grids and glass furnaces, applied in separation methods, chemical instruments and methods, furnaces, etc., can solve problems such as manual cleaning of flue dust, burial of ammonia spraying grid dust accumulation, ammonia spraying grid coverage, etc. , to achieve long-term stable operation, avoid the risk of dust accumulation in the flue, and ensure the effect of kiln pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

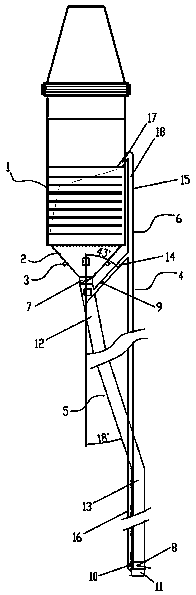

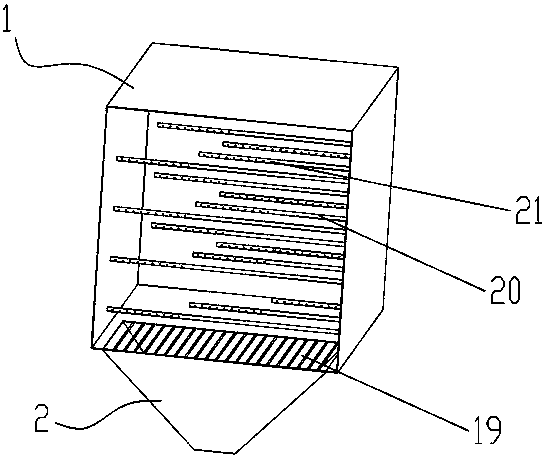

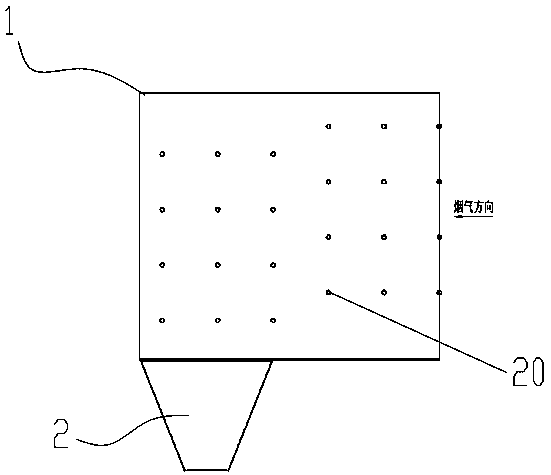

[0039] exist figure 1 , figure 2 In the shown embodiment, an online ash cleaning device for glass kiln flue gas denitrification and ammonia injection grid includes:

[0040] Ammonia injection grid 1, a device for injecting ammonia;

[0041] Ash hopper device 2, ash hopper device 2 is arranged under ammonia spray grid 1 and communicated with ammonia spray grid 1; ash hopper device 2 is provided with vibration device 3;

[0042] The circulation channel 4 is used to realize the communication and circulation of flue gas; the circulation channel 4 communicates with the ammonia injection grid 1 and the ash hopper device 2 respectively through the control valve, and forms the internal circulation of the flue gas and the flue ash under the pressure maintaining state.

[0043] Circulation channel 4 includes ash lowering pipeline 5 and communication pipeline 6 which communicate with each other; the control valve includes: ash lowering electric magnetic valve 7 set on the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com