Vacuum stirring equipment of lithium battery slurry

A technology of vacuum stirring and lithium battery, which is applied in the direction of mixer accessories, dissolving, mixing machines, etc., can solve the problems of inability to ensure the cleaning of the inner wall of the mixer, a large amount of manpower and material resources, and inconvenient cleaning, so as to reduce the workload of manual operations, speed up efficiency, enhances the effect of symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

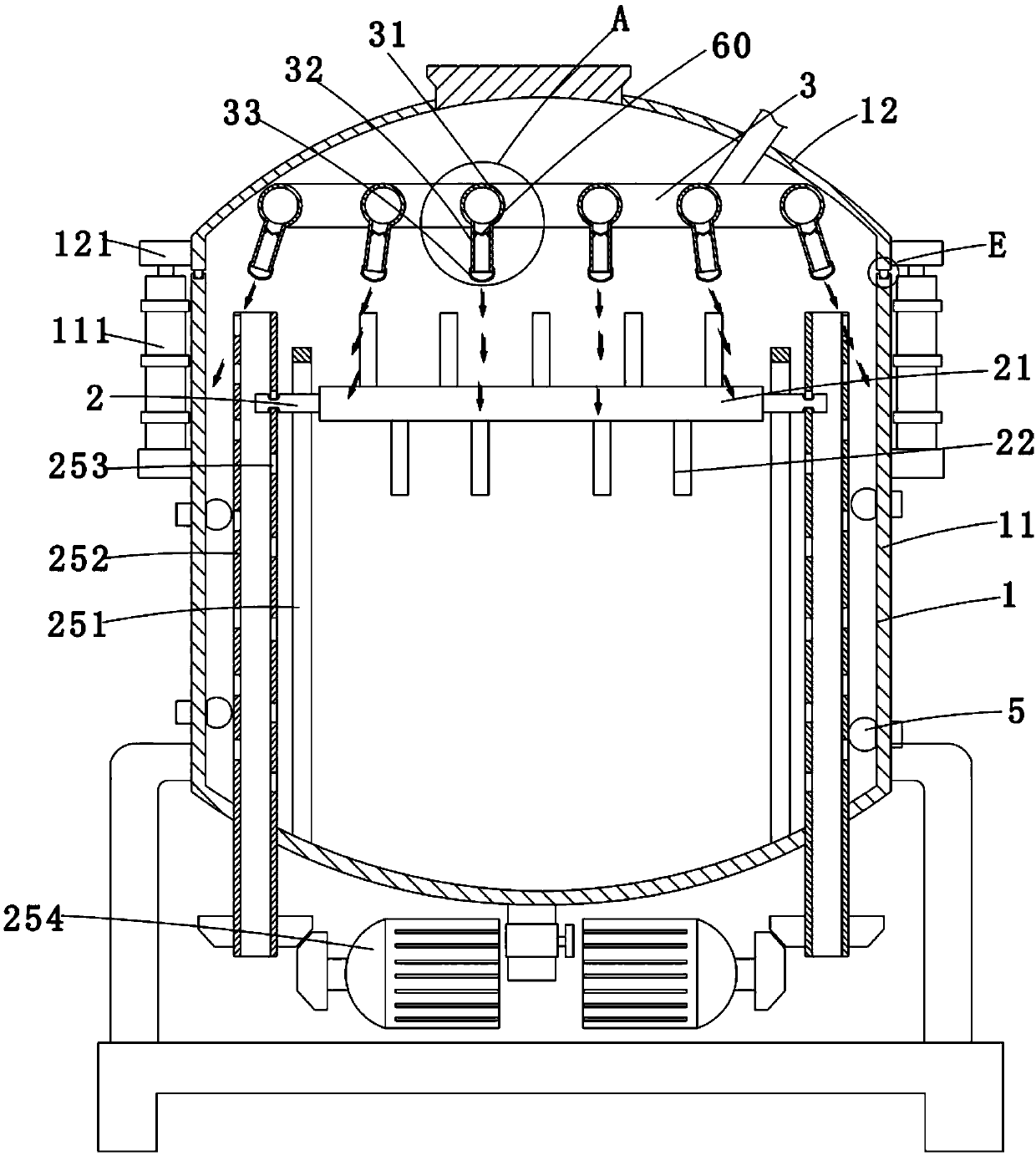

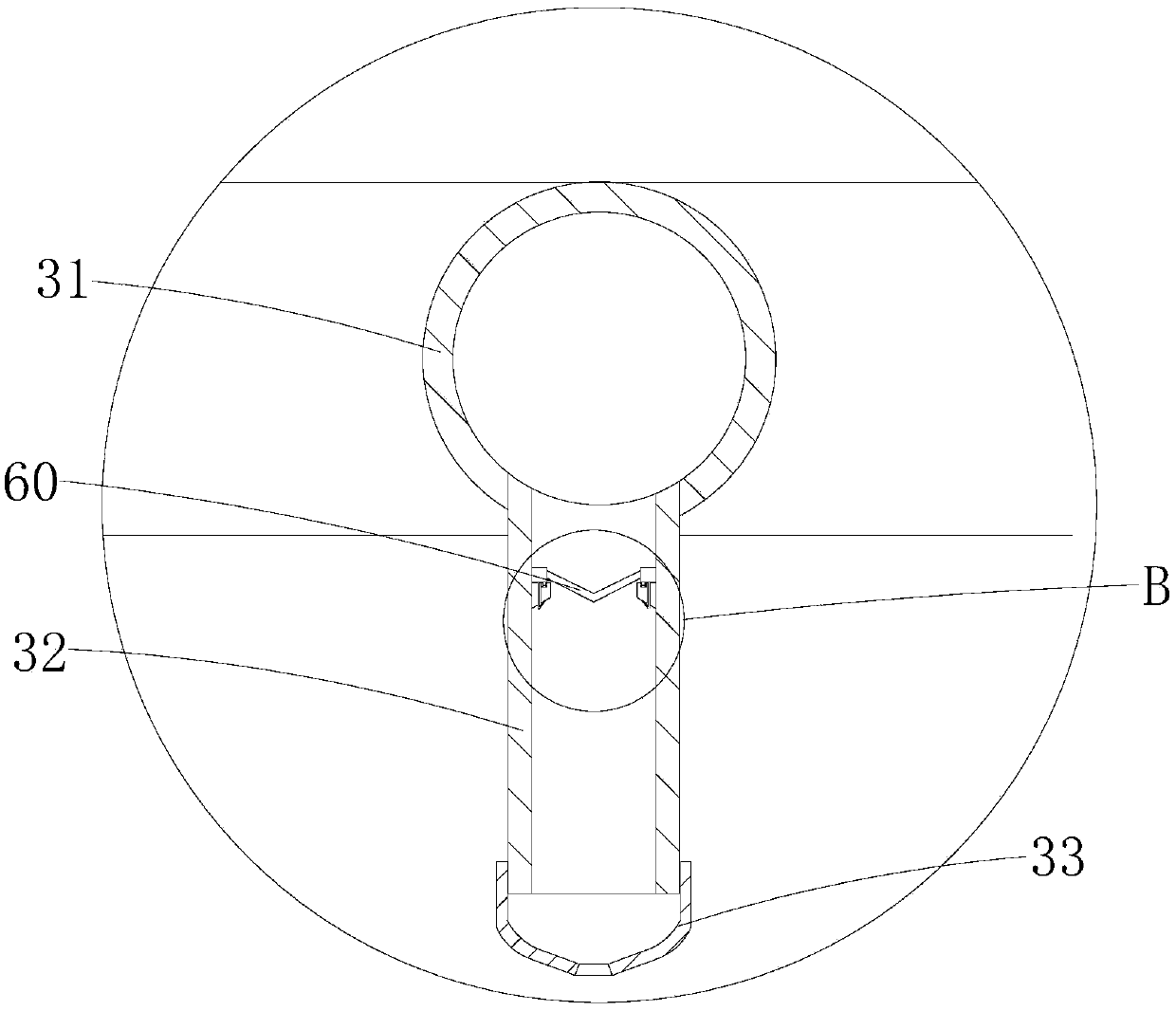

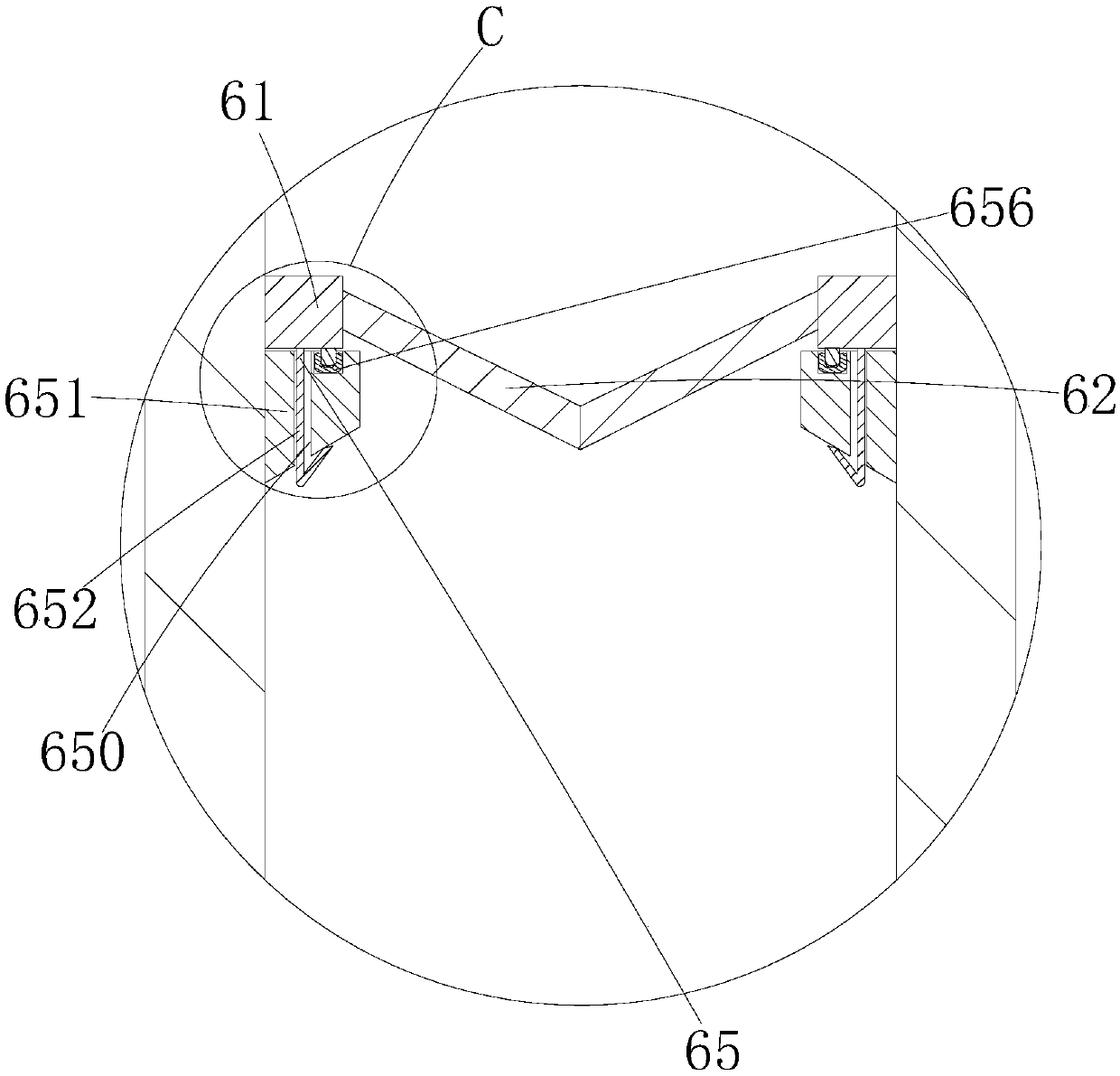

[0032] Such as Figure 1-9 As shown, a lithium battery slurry vacuum stirring equipment includes a material tank 1, a stirring device 2, a cleaning part 3, a vacuuming part 4 and an ultrasonic part 5, and the material tank 1 includes a tank body 11 and a cover body 12. The tank body 11 is a metal bucket, and the cover body 12 is also a metal cover. The cover body 12 can be covered on the tank body 11, and the cover body 12 is provided with connecting ears 121. A cylinder 111 is fixed on the side wall of the body 11, and the end of the cylinder 111 is connected with the connecting ear 121, so that the cover 12 can be opened under the push of the cylinder 111, and the Under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com