Surface spraying device for compressor cylinder body

A technology of surface spraying and spraying equipment, applied in the direction of spraying equipment, spray booths, etc., can solve the problems of damaging the workpiece coating, wasting time and manpower, etc., and achieve the effect of improving corrosion resistance

Inactive Publication Date: 2018-12-28

安徽省华欣能源装备科技有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, in the process of compressor cylinder processing, it is often necessary to spray the surface of the compressor cylinder in order to produce and prepare compressor cylinders that meet the requirements. Spraying is an important part of the surface manufacturing process, anti-rust, anti-corrosion, The disadvantage of aesthetics and changing the use of the material itself is that the quality of spraying is one of the important aspects of overall quality. The quality of product appearance not only reflects the protection and decoration performance of the product, but also an important factor that constitutes the value of the product. Usually, it is necessary to inspect the product after spraying. Carrying out transfer and drying, in this process not only wastes time and manpower, but also may damage the coating on the workpiece during the transfer process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

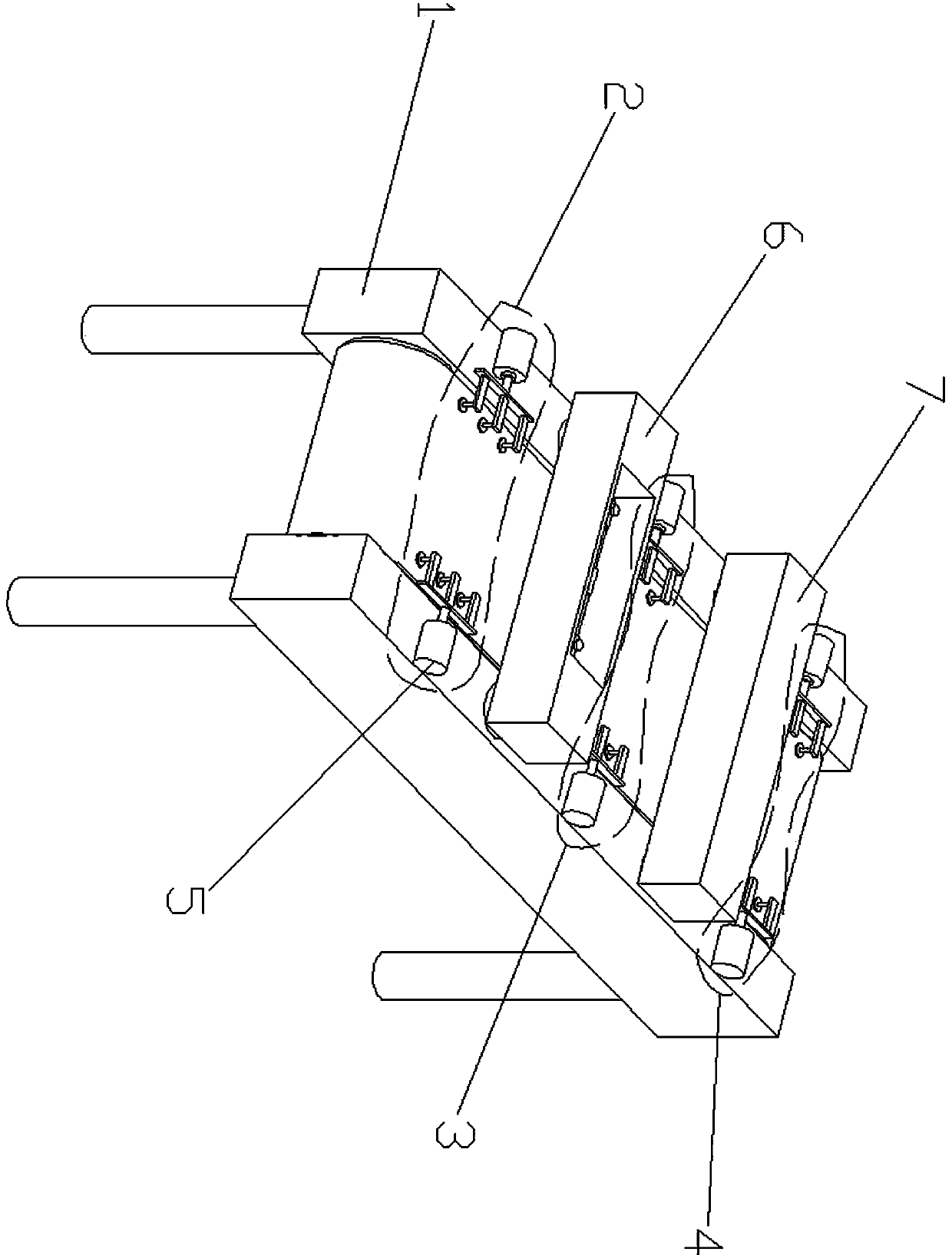

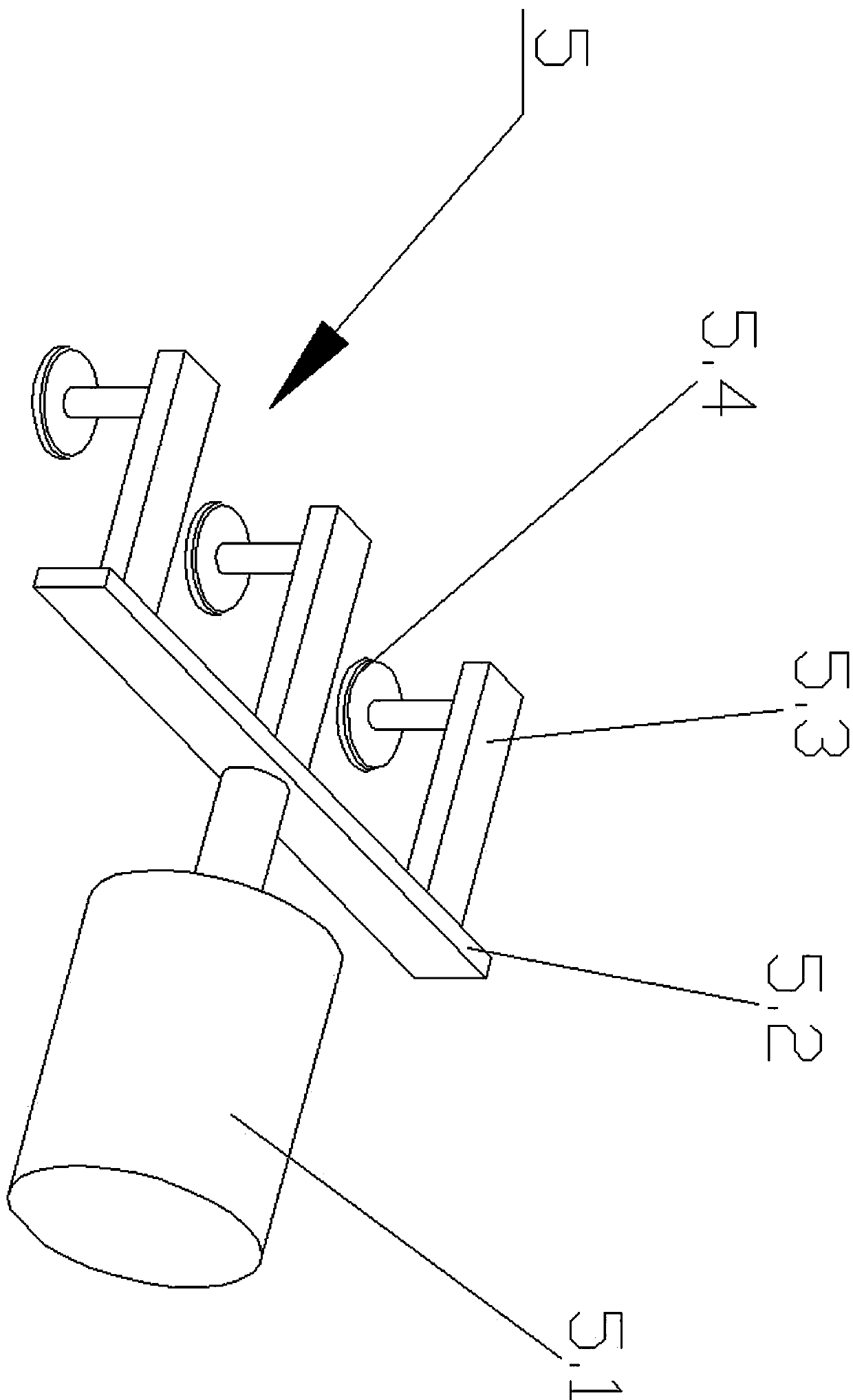

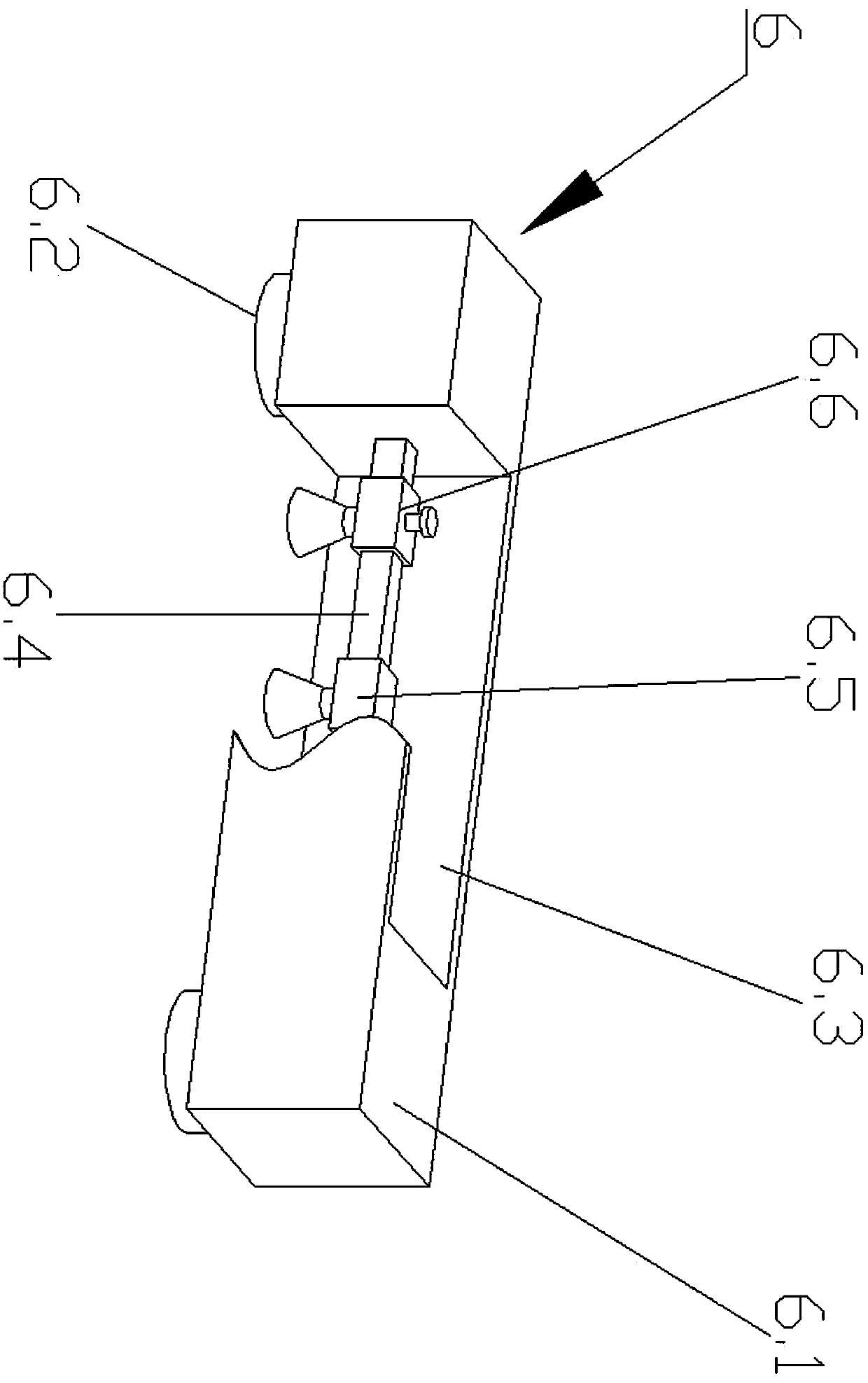

The invention relates to the field of compressor production, in particular to a surface spraying device for a compressor cylinder body. The surface spraying device comprises a conveying belt, whereina first fixing assembly, a second fixing assembly and a third fixing assembly are arranged on a stand of the conveying belt in sequence; the structures of the first fixing assembly, the second fixingassembly and the third fixing assembly are the same, and each of the fixing assemblies comprises two symmetrically arranged fixing pieces; the two fixing pieces are respectively arranged on two sidesof the stand of the conveying belt; a spraying device is arranged between the first fixing assembly and the second fixing assembly; the spraying device is arranged on the stand of the conveying belt;a drying device is arranged between the second fixing assembly and the third fixing assembly; and the drying device is arranged on the stand of the conveying belt. The surface spraying device has theadvantages that the device can spray a coating to an aluminum alloy and improve the corrosion resistance performance, the heat isolation property and the like of the compressor cylinder body; and thesurface spraying device is further provided with the drying device, so that the coating can be quickly dried.

Description

technical field The invention relates to the technical field of compressor production, in particular to a surface spraying device for a compressor cylinder body. Background technique At present, in the process of compressor cylinder processing, it is often necessary to spray the surface of the compressor cylinder in order to produce and prepare compressor cylinders that meet the requirements. Spraying is an important part of the surface manufacturing process, anti-rust, anti-corrosion, The disadvantage of aesthetics and changing the use of the material itself is that the quality of spraying is one of the important aspects of overall quality. The quality of product appearance not only reflects the protection and decoration performance of the product, but also an important factor that constitutes the value of the product. Usually, it is necessary to inspect the product after spraying. Transshipment drying not only wastes time and manpower in the process, but also may damage th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B05B16/20B05B13/04B05B13/02

CPCB05B16/20B05B13/0221B05B13/041

Inventor 凌应战李传继

Owner 安徽省华欣能源装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com