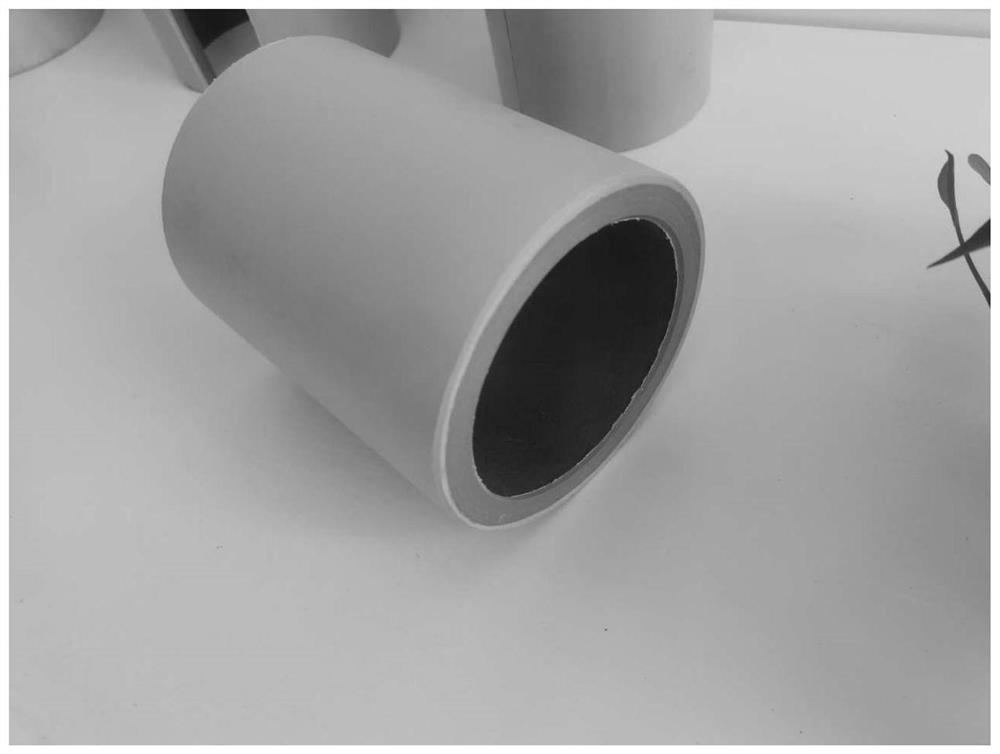

Graphene wear-resistant PE composite material for carrier roller and preparation method of composite material

A composite material and graphene technology are applied in the field of graphene wear-resistant PE composite materials for idlers and their preparation, and can solve the problems of difficult processing and molding, low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

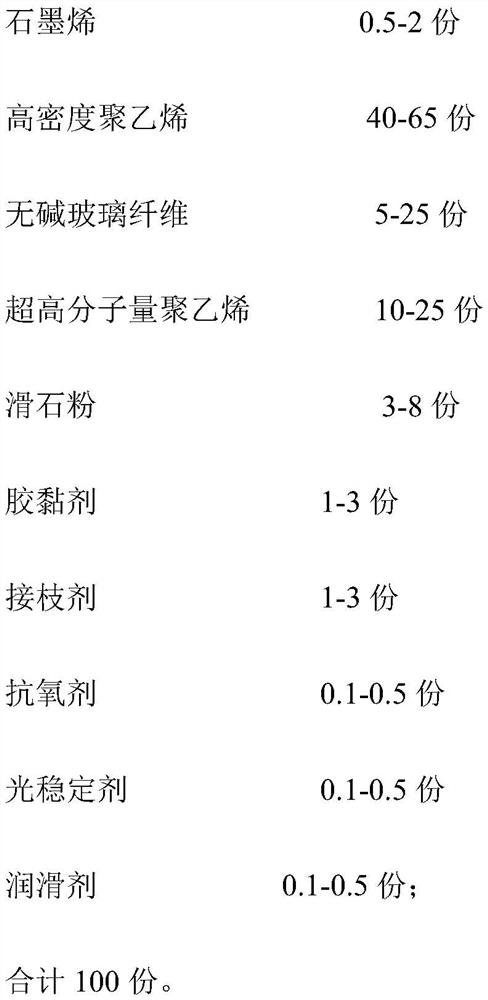

[0063] A graphene wear-resistant PE composite material for an idler roller of the present invention is prepared from the following components in weight percentage:

[0064] 0.5% graphene, 60% high-density polyethylene, 10% alkali-free glass fiber, 15% ultra-high molecular weight polyethylene, 8% talcum powder, 2.5% adhesive, 3% grafting agent, 0.4% antioxidant, Light stabilizer 0.2%, lubricant 0.4%.

[0065] Among them, the parameters of graphene are: specific surface area 420m 2 / g, the particle diameter D50 is 25 μm, and the oxygen content of graphene is 2%;

[0066] The melt index of high-density polyethylene is 18g / 10min;

[0067] E-glass fiber diameter is 13 microns;

[0068] The average molecular weight of ultra-high molecular weight polyethylene is 2.5 million;

[0069] The particle size of talcum powder is 2000 mesh;

[0070] The adhesive is EVA;

[0071] The grafting agent is PE-g-MAH;

[0072] The antioxidants are antioxidant 1010 and antioxidant 168;

[0073...

Embodiment 2

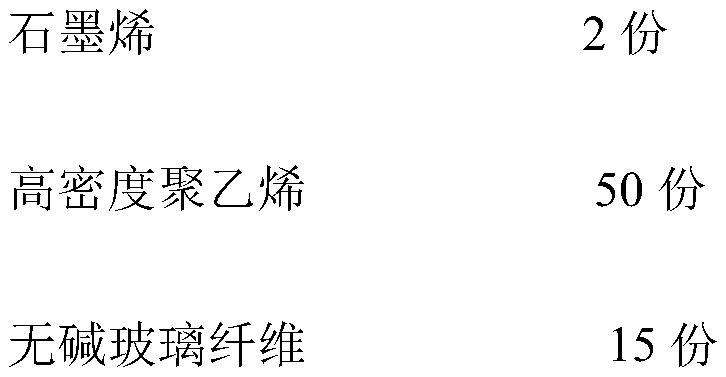

[0079] A graphene wear-resistant PE composite material for an idler roller of the present invention is prepared from the following components in weight percentage:

[0080] 1% graphene, 55% high-density polyethylene, 15% alkali-free glass fiber, 15% ultra-high molecular weight polyethylene, 8% talc, 3% adhesive, 2% grafting agent, 0.4% antioxidant, Light stabilizer 0.2%, lubricant 0.4%.

[0081] Among them, the parameters of graphene are: specific surface area 420m 2 / g, the particle diameter D50 is 25 μm, and the oxygen content of graphene is 2%;

[0082] The melt index of high-density polyethylene is 18g / 10min;

[0083] E-glass fiber diameter is 13 microns;

[0084] The average molecular weight of ultra-high molecular weight polyethylene is 2.5 million;

[0085] The particle size of talcum powder is 2000 mesh;

[0086] The adhesive is EVA;

[0087] The grafting agent is PE-g-MAH;

[0088] The antioxidants are antioxidant 1010 and antioxidant 168;

[0089] The light s...

Embodiment 3

[0095] A graphene wear-resistant PE composite material for an idler roller of the present invention is prepared from the following components in weight percentage:

[0096] Graphene 1.5%, high-density polyethylene 50%, alkali-free glass fiber 20%, ultra-high molecular weight polyethylene 20%, talcum powder 3%, adhesive 2%, grafting agent 2.5%, antioxidant 0.4%, Light stabilizer 0.2%, lubricant 0.4%.

[0097] Among them, the parameters of graphene are: specific surface area 420m 2 / g, the particle diameter D50 is 25 μm, and the oxygen content of graphene is 2%;

[0098] The melt index of high-density polyethylene is 18g / 10min;

[0099] E-glass fiber diameter is 13 microns;

[0100] The average molecular weight of ultra-high molecular weight polyethylene is 2.5 million;

[0101] The particle size of talcum powder is 2000 mesh;

[0102] The adhesive is EVA;

[0103] The grafting agent is PE-g-MAH;

[0104] The antioxidants are antioxidant 1010 and antioxidant 168;

[0105] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com