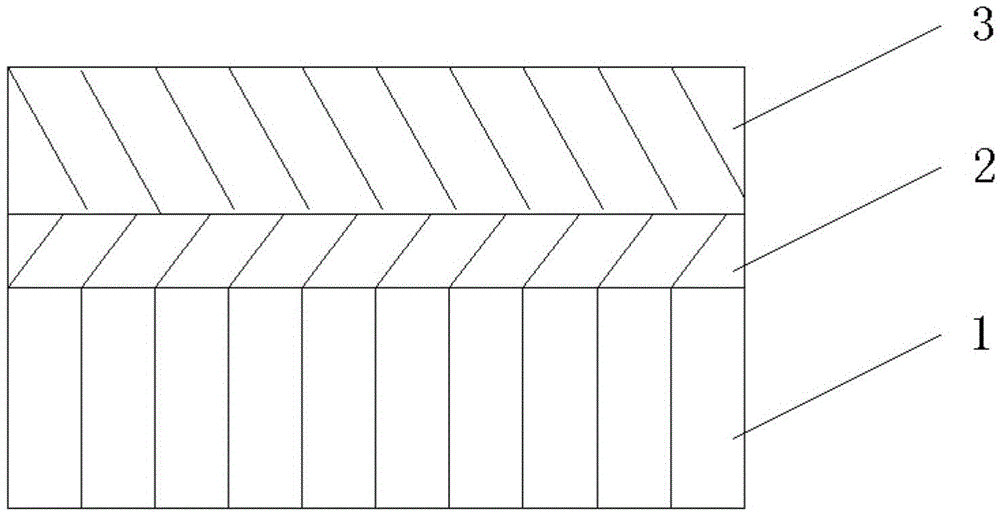

Chemically-plated Ni-P/Ni-Mo-P-PTFE composite structure plating layer and preparation method thereof

A ni-mo-p-ptfe, composite structure technology, applied in liquid chemical plating, coating, metal material coating process, etc., can solve the difficult management of sewage source heat pump, increase maintenance workload, sewage flow blockage and other problems, to prevent adhesion and crystallization, uniform coating, and improve anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

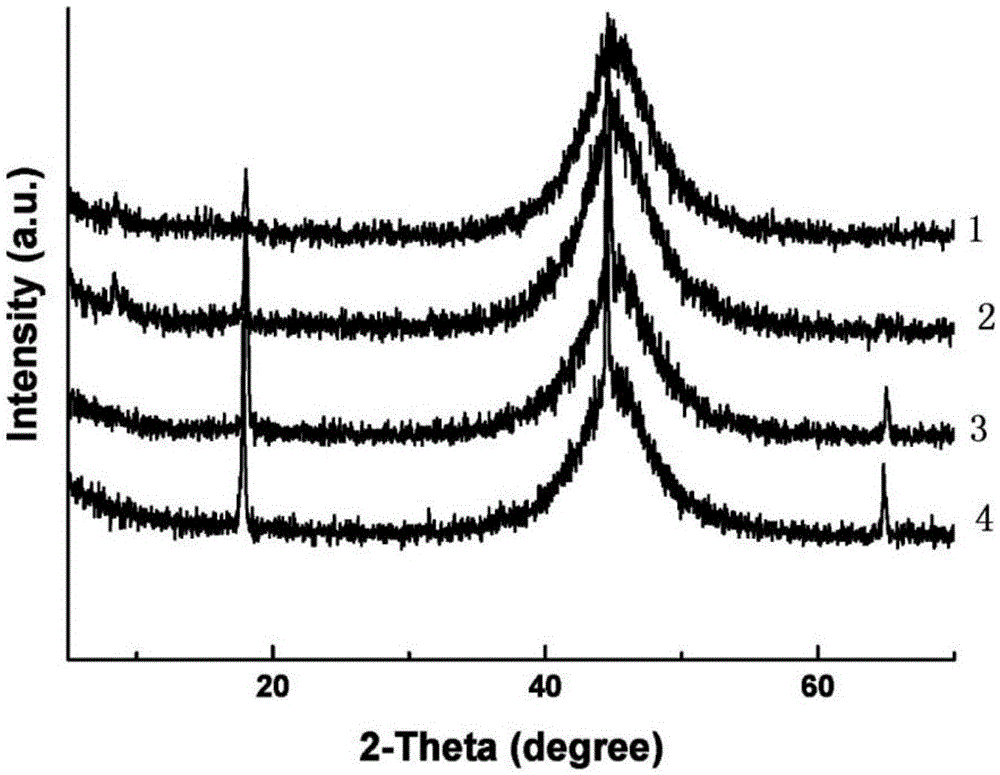

Embodiment 1

[0024] (1) Degreasing, pickling, and activation: After cleaning the metal substrate in deionized water, put it in an acetone solution for ultrasonic cleaning for 2-3 minutes, the ultrasonic frequency is 40KHz, and the power is 2KW. After cleaning with deionized water again, put Put it into 10wt% sodium hydroxide solution to remove oil, the oil removal time is 15-20min, then put it into 70°C deionized water for cleaning, after cleaning, put it into 36.5wt% concentrated hydrochloric acid for activation for 2-3min;

[0025] (2) Plating once: Plating solution A comprises the following components: nickel sulfate 20g / L; sodium hypophosphite 10g / L; citric acid 2g / L; sodium acetate 10g / L; The substrate is placed in the plating solution A for chemical deposition plating, and the deposition time is 1h;

[0026] (3) Secondary plating: Plating solution B includes the following components: nickel sulfate 20g / L; sodium hypophosphite 16.5g / L; sodium molybdate: 1.5g / L; sodium acetate 8.5g / L; ...

Embodiment 2

[0031] (1) Degreasing, pickling, and activation: After cleaning the metal substrate in deionized water, put it in an acetone solution for ultrasonic cleaning for 2-3 minutes, the ultrasonic frequency is 40KHz, and the power is 2KW. After cleaning with deionized water again, put Put it into 10wt% sodium hydroxide solution to remove oil, the oil removal time is 15-20min, then put it into 70°C deionized water for cleaning, after cleaning, put it into 36.5wt% concentrated hydrochloric acid for activation for 2-3min;

[0032] (2) Plating once: Plating solution A comprises the following components: nickel sulfate 25g / L; sodium hypophosphite 8g / L; citric acid 1g / L; sodium acetate 8g / L; The substrate is placed in the plating solution A for chemical deposition plating, and the deposition time is 1h;

[0033] (3) Secondary plating: Plating solution B includes the following components: nickel sulfate 12g / L; sodium hypophosphite 10g / L; sodium molybdate: 0.1g / L; sodium acetate 5g / L; glycin...

Embodiment 3

[0038] (1) Degreasing, pickling, and activation: After cleaning the metal substrate in deionized water, put it in an acetone solution for ultrasonic cleaning for 2-3 minutes, the ultrasonic frequency is 40KHz, and the power is 2KW. After cleaning with deionized water again, put Put it into 10wt% sodium hydroxide solution to remove oil, the oil removal time is 15-20min, then put it into 70°C deionized water for cleaning, after cleaning, put it into 36.5wt% concentrated hydrochloric acid for activation for 2-3min;

[0039] (2) Plating once: Plating solution A comprises the following components: nickel sulfate 15g / L; sodium hypophosphite 20g / L; citric acid 5g / L; sodium acetate 15g / L; The substrate is placed in the plating solution A for chemical deposition plating, and the deposition time is 1h;

[0040] (3) Secondary plating: Plating solution B includes the following components: nickel sulfate 30g / L; sodium hypophosphite 20g / L; sodium molybdate: 3.3g / L; sodium acetate 15g / L; gly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com