Dismantling method of scrapped photovoltaic module

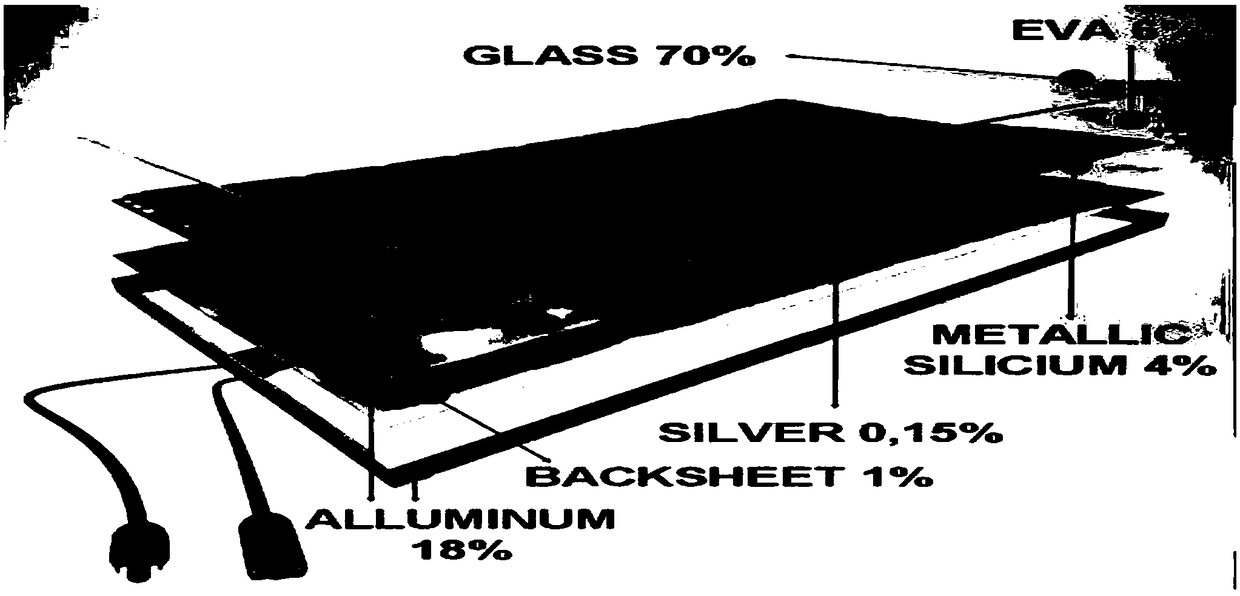

A photovoltaic module, liquid technology, applied in waste treatment, electronic waste recycling, solid waste removal and other directions, can solve problems such as incompleteness and failure to separate, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The dismantling method of scrapped photovoltaic modules includes the following steps:

[0043] 1) Disassemble the aluminum frame

[0044] The automatic frame dismantling machine is used to completely remove the aluminum frame by increasing the outward expansion of the aluminum frame of the scrapped photovoltaic module;

[0045] 2) Disassemble the junction box

[0046] Use a blade to manually disassemble the junction box;

[0047] 3) Defluorination film

[0048] The fluorine film is located on the outermost layer of the scrapped photovoltaic module backplane. The fluorine film is removed by controlling the pressure and angle of the fluid sprayed from the spray gun; 100kg / cm 2 ; The distance between the nozzle of the spray gun and the target is 0.1 meters, and the angle between the sprayed object and the target is 30°.

[0049] 4) Remove the back panel

[0050] The backboard material is closely combined with the silicon wafer through the EVA glue layer, and the back...

Embodiment 2

[0059] The dismantling method of scrapped photovoltaic modules includes the following steps:

[0060] 1) Disassemble the aluminum frame

[0061] The automatic frame dismantling machine is used to completely remove the aluminum frame by increasing the outward expansion of the aluminum frame of the scrapped photovoltaic module;

[0062] 2) Disassemble the junction box

[0063] Use a blade to manually disassemble the junction box;

[0064] 3) Defluorination film

[0065] The fluorine film is located on the outermost layer of the backplane of the scrapped photovoltaic module. The fluorine film is removed by controlling the pressure and angle of the liquid sprayed from the spray gun; the spray gun sprays sand, and the sand flows out of the spray gun mouth in a flow shape. The spray pressure is 200kg / cm 2 ; The distance between the nozzle of the spray gun and the target is 1.5 meters, and the angle between the sprayed object and the target is 45°.

[0066] 4) Remove the back pa...

Embodiment 3

[0076] The dismantling method of scrapped photovoltaic modules includes the following steps:

[0077] 1) Disassemble the aluminum frame

[0078] The automatic frame dismantling machine is used to completely remove the aluminum frame by increasing the outward expansion of the aluminum frame of the scrapped photovoltaic module;

[0079] 2) Disassemble the junction box

[0080] Use a blade to manually disassemble the junction box;

[0081] 3) Defluorination film

[0082] The fluorine film is located on the outermost layer of the backplane of the scrapped photovoltaic module, and the fluorine film is removed by controlling the pressure and angle of the liquid sprayed from the spray gun; the spray gun sprays sand, which is in the form of mist when it flows out of the spray gun mouth, and the spray pressure is 150kg / cm 2 ; The distance between the nozzle of the spray gun and the target is 1 meter, and the angle between the sprayed object and the target is 35°.

[0083] 4) Remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com