Push bending forming device adopting push-pull integrated loading and method

An integrated, supporting device technology, applied in the field of pipe bending and forming, can solve the problems of difficulty in precise angle positioning, large footprint, and difficult adjustment, and achieve the effect of reducing manufacturing costs, reducing production time, and not easy to wrinkle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

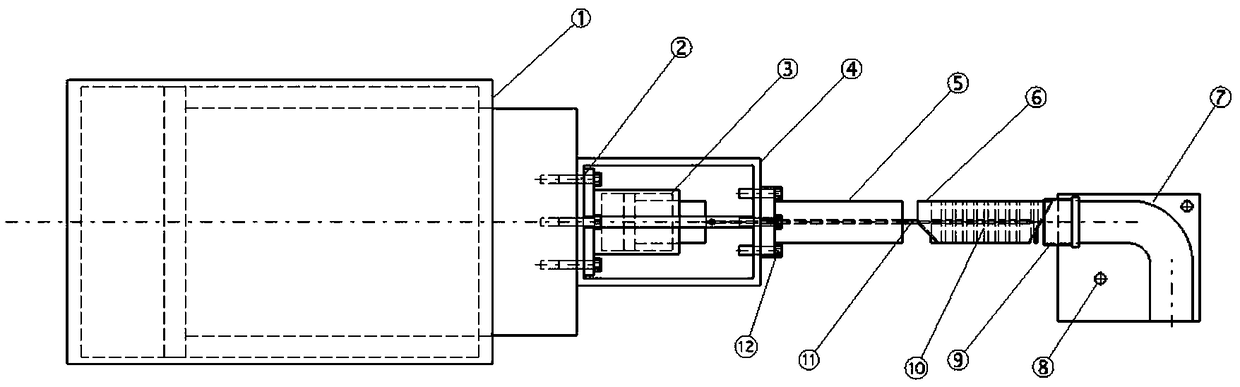

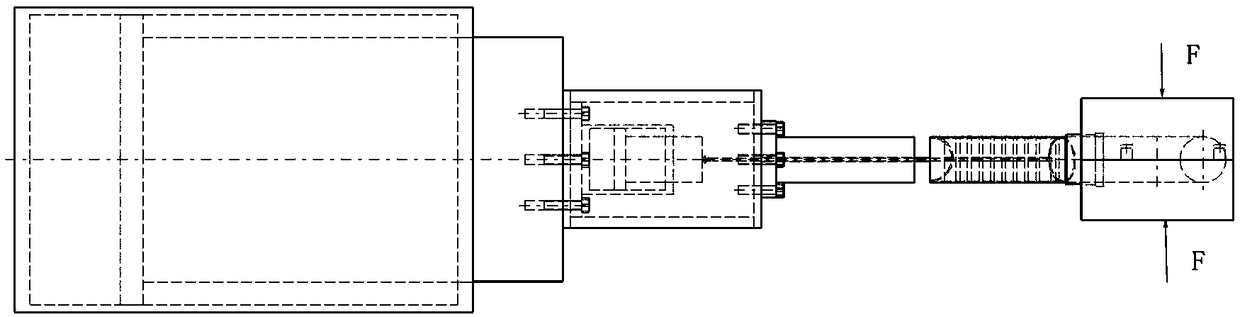

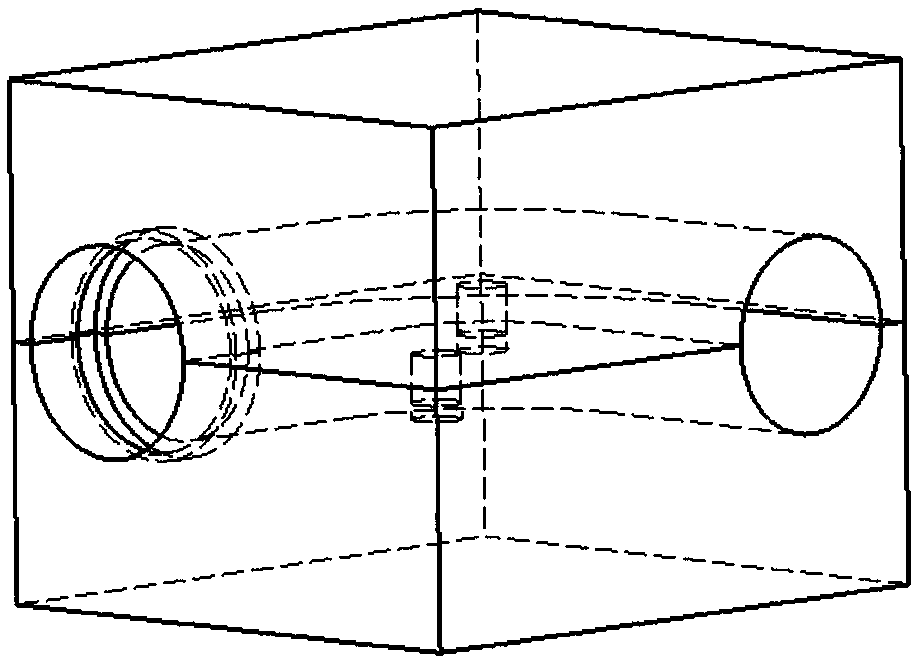

[0040] Such as Figure 1-5 As shown, the present embodiment provides a push bending forming device that adopts push-pull integrated loading, including a main push cylinder 1, a support device, a push rod 5, a blank tube 6 and a mold 7, the support device is installed on the output end of the main push cylinder 1, and the push One end of the rod 5 is installed on the front end of the support device, specifically, the support device includes a support box 4, the rear end surface of the support box 4 is fixed on the output end of the main push cylinder 1 by the first locking bolt 2, and the tail of the push rod 5 The end is fixed on the front end surface of the supporting box 4 by the second locking bolt 12 . The mold 7 is located in front of the blank tube 6, and the other end of the push rod 5 is used to push the blank tube 6 to move towards the mold 7, and the end of the mold 7 close to the blank tube 6 is provided with a guide sleeve 9 to precisely guide the blank tube 6 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com