Vertical shaft type cantilever robot

A robot, vertical axis technology, applied in the field of truss robots, can solve the problems of inconvenient transfer, high labor cost, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

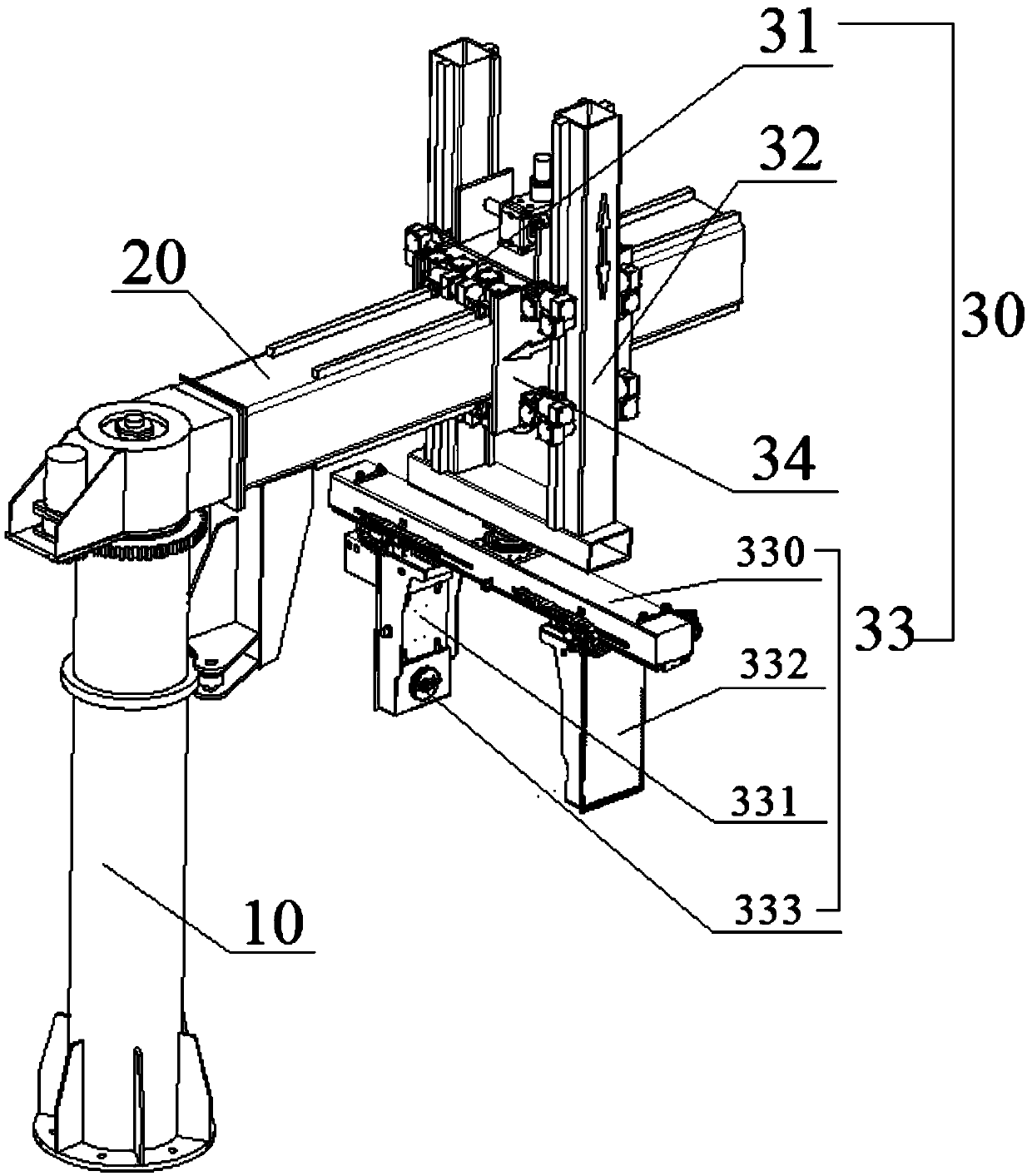

[0023] A vertical axis type cantilever robot, comprising a column 10, a rotating beam 20, and a manipulator 30; the manipulator 30 is installed on the rotating beam 20, and one end of the rotating beam 20 is axially connected to the column 10; the rotating beam 20 includes an extension arm 21 and a shaft part 22 , the support part 23, the rotating shaft part 22 is arranged on the extension arm 21, and is connected with the column 10 axis, and the extension arm 21 is slidably connected with the manipulator 30, and one end of the support part 23 is connected with the extension arm 21, and the other end is connected with the column 10 Swipe to connect.

[0024] Using the column 10 and the rotating beam 20 improves the gripping ability of the manipulator 30, so that within a certain range, the manipulator 30 can complete the work of grabbing or carrying heavy objects.

Embodiment 2

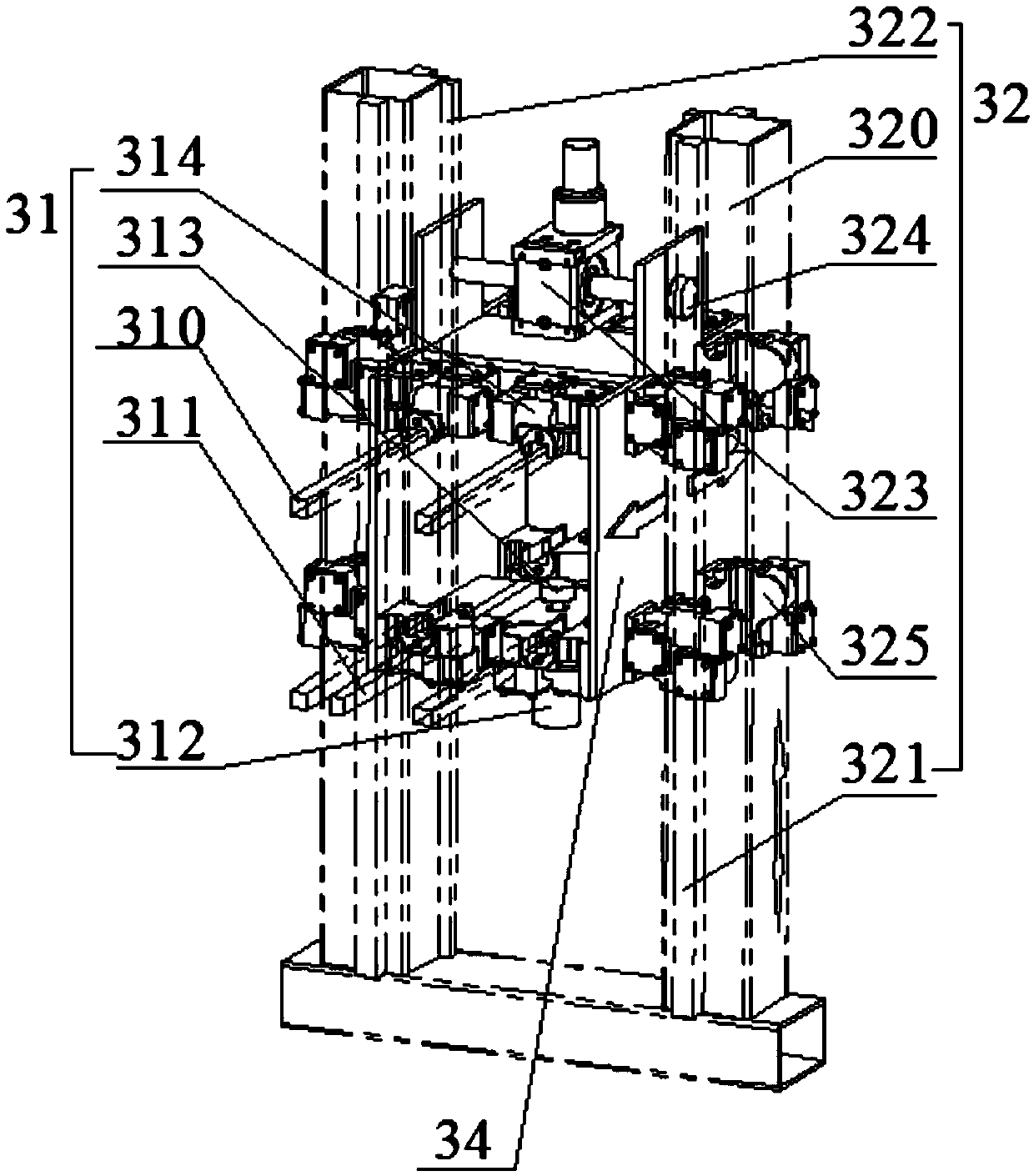

[0026] A vertical axis type cantilever robot, comprising a column 10, a rotating beam 20, and a manipulator 30; the manipulator 30 is installed on the rotating beam 20, and one end of the rotating beam 20 is axially connected to the column 10; the rotating beam 20 includes an extension arm 21 and a shaft part 22 , the support part 23, the rotating shaft part 22 is arranged on the extension arm 21, and is connected with the column 10 axis, the extension arm 21 is slidably connected with the manipulator 30, the support part 23 includes a fixed arm 230, a pulley 231, a slide rail 232, fixed One end of the arm 230 is fixedly connected with the extension arm 21 , and the other end is provided with a pulley 231 , and the column 10 is provided with a slide rail 232 , and the pulley 231 slides along the slide rail 232 .

[0027] The support part 23 is provided with at least two pulleys 231, and the slide rail 232 forms a circle around the column 10. The side of the fixed arm 230 where ...

Embodiment 3

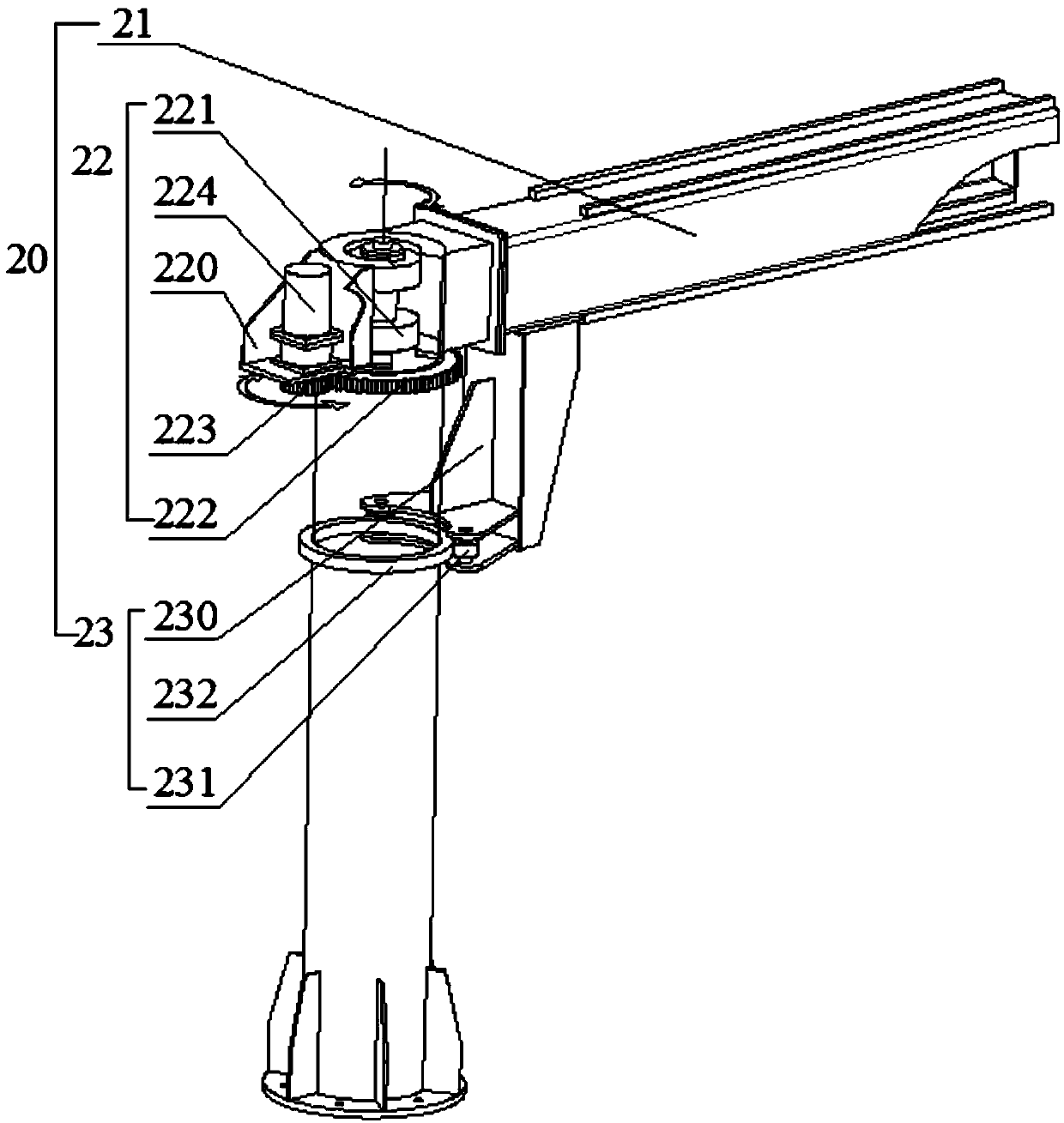

[0030] Refer to attached figure 2 Shown, a kind of vertical axis type cantilever robot comprises column 10, rotating beam 20, manipulator 30; Manipulator 30 is installed on the rotating beam 20, and one end of rotating beam 20 is connected with column 10 axis; Rotating beam 20 comprises extending arm 21, The rotating shaft part 22, the support part 23, the rotating shaft part 22 is arranged on the extension arm 21, and is connected with the column 10 axis, on the extension arm 21, a manipulator 30 is slidably connected, and the support part 23 includes a fixed arm 230, a pulley 231, a slide rail 232 , one end of the fixed arm 230 is fixedly connected with the extension arm 21 , and the other end is provided with a pulley 231 , the column 10 is provided with a slide rail 232 , and the pulley 231 slides along the slide rail 232 .

[0031] The rotating shaft part 22 includes a housing 220, a bearing 221, a fixed gear 222, a rotating gear 223, and a driving device 224. The bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com