cutting device

A technology for cutting devices and workpieces, which is applied in the direction of instruments, televisions, work accessories, etc., can solve the problem of inaccurate measurement of cutting groove width, etc., and achieve the effects of shortening time, efficient shooting, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

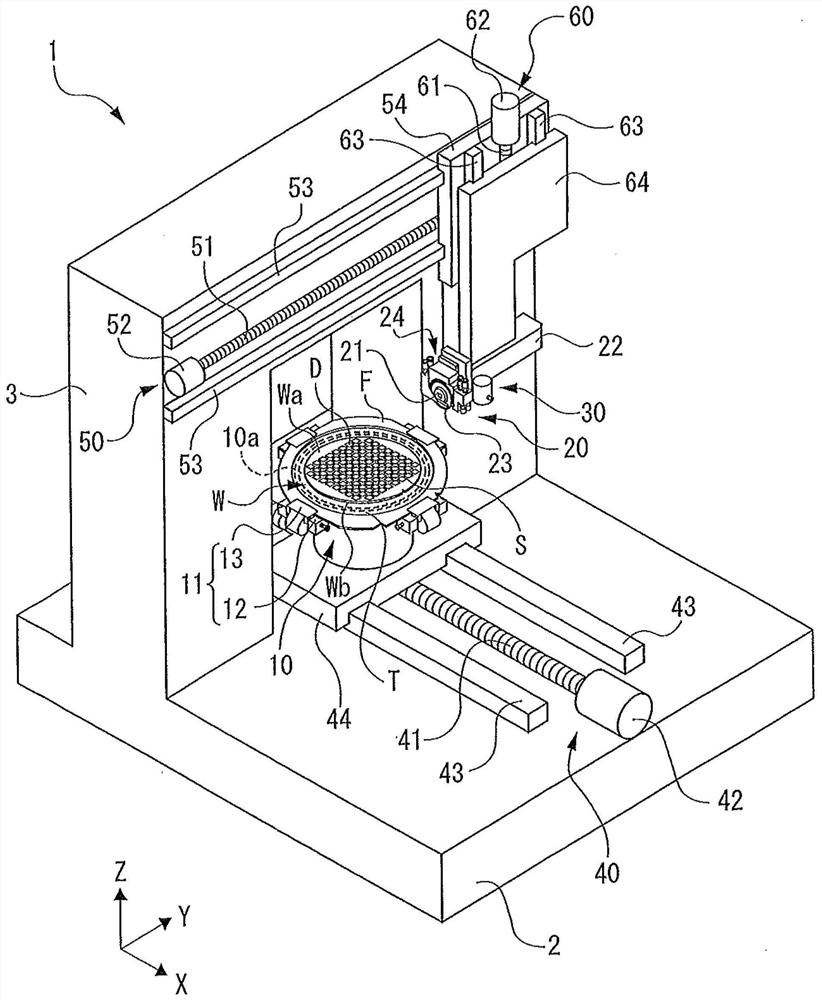

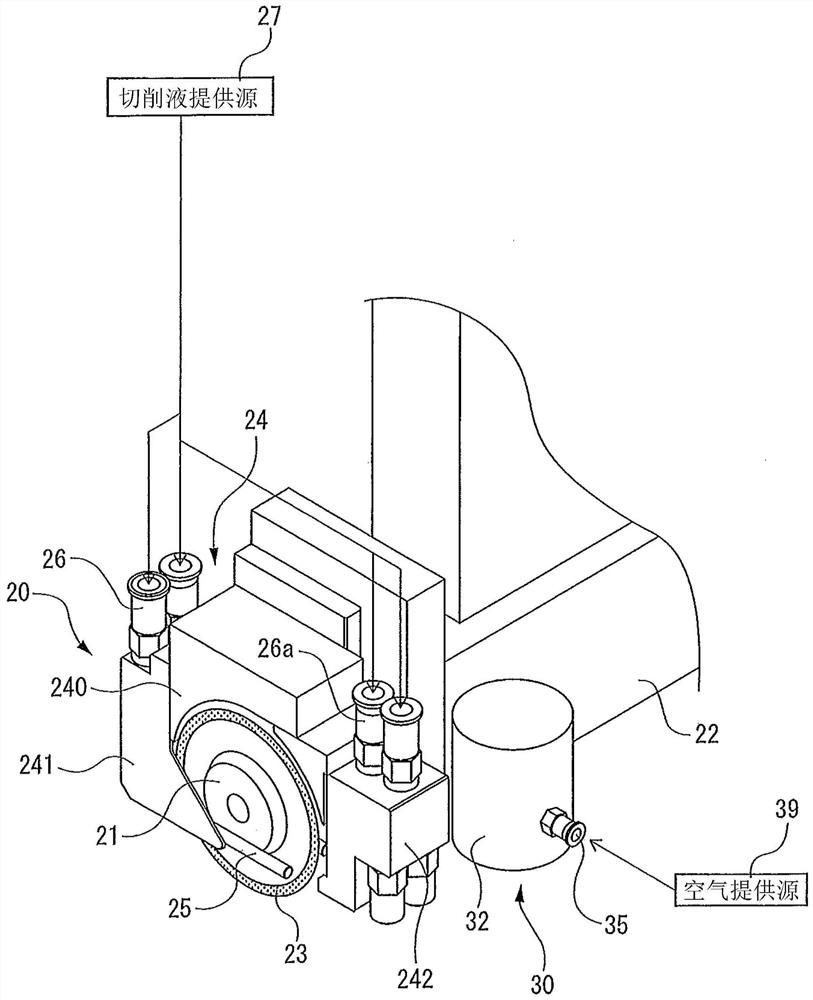

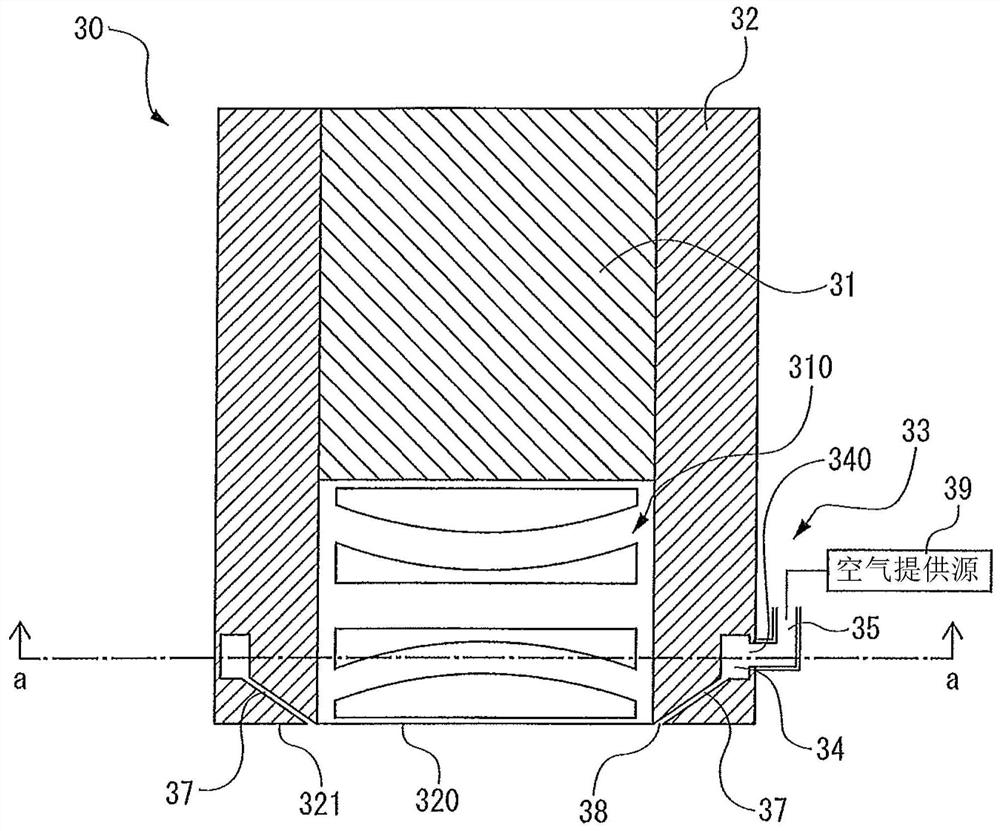

[0024] figure 1 The cutting device 1 shown has a device base 2, and includes: a holding table 10 disposed on the device base 2 for holding a plate-shaped workpiece W as a workpiece; a cutting unit 20 for holding The cutting tool 23 is rotatably mounted, and performs cutting while supplying cutting water to the plate-shaped workpiece W held by the holding table 10; the imaging unit 30 photographs the plate-shaped workpiece W held by the holding table 10 from above. ; the moving unit 40, which makes the holding table 10 and the imaging unit 30 relatively move in the cutting feed direction (X-axis direction); The cutting unit 20 performs index feeding; and the raising and lowering unit 60 raises and lowers the cutting unit 20 in the vertical direction (Z-axis direction).

[0025] The upper surface of the holding table 10 serves as a holding surface 10a for holding the plate-shaped workpiece W. As shown in FIG. A plurality of frame holding units 11 for holding an annular frame F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com