Inner plate wall for building intelligent installation project and preparation method thereof

An installation engineering and intelligent technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of poor sound insulation effect, poor load-bearing effect, and difficult installation of the inner panel wall, and achieve good fixed and limited effects, easy to install, etc. Disassembly and splicing, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

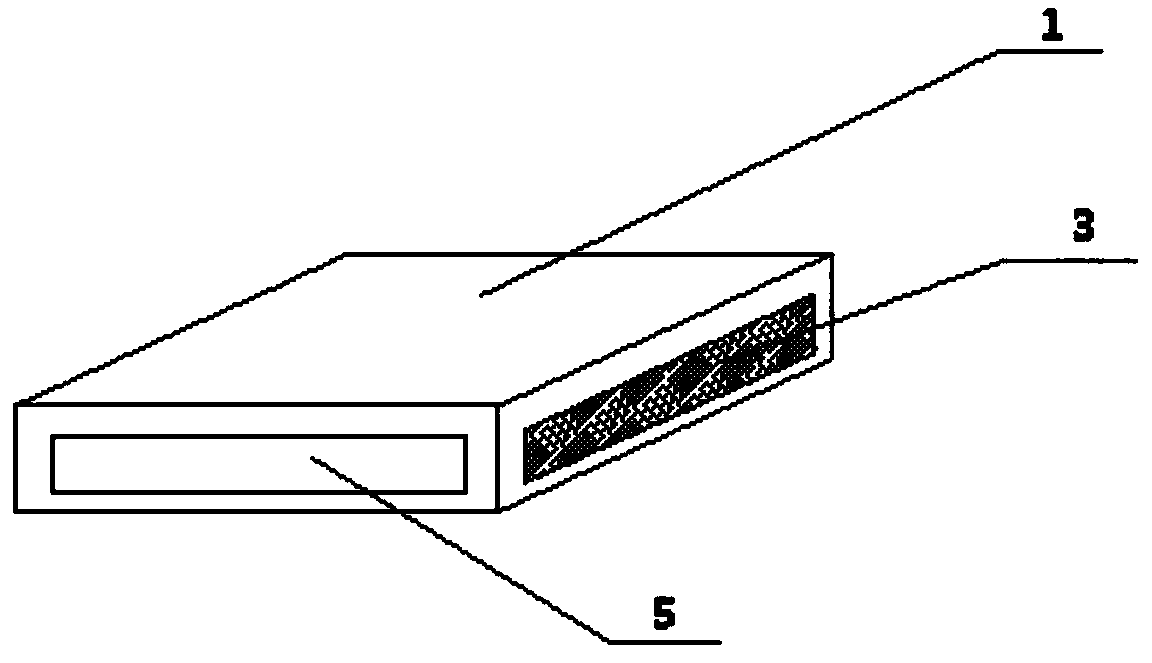

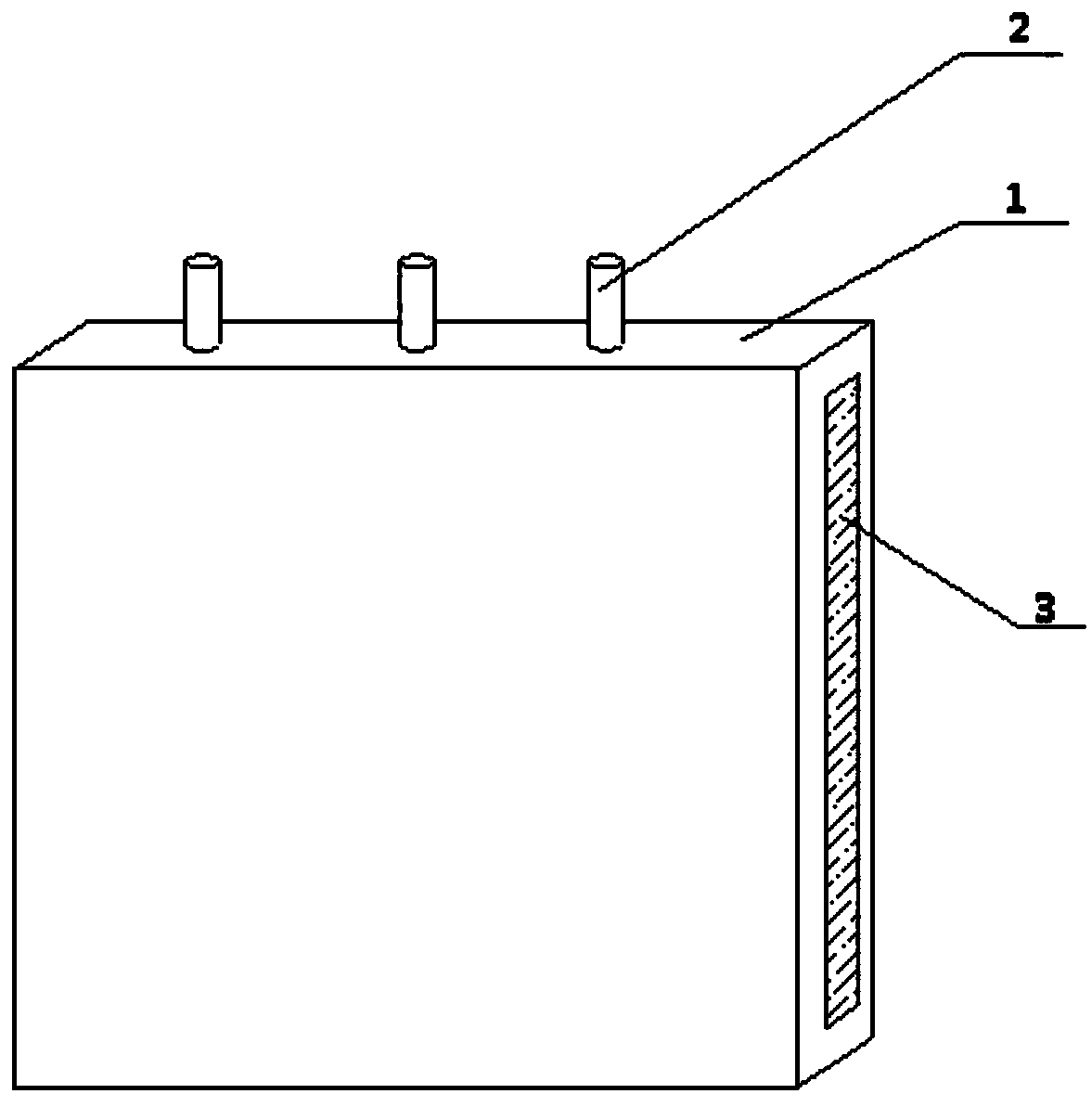

[0050] An inner panel wall for building intelligent installation engineering, including a wall body, a vertical fixing column, a magnetic panel and a metal panel:

[0051] The vertical fixing column is installed in the groove at the top of the wall;

[0052] The magnetic plate is fixedly installed in the groove on the right side of the wall;

[0053] The metal plate is fixedly installed in the groove on the left side of the wall;

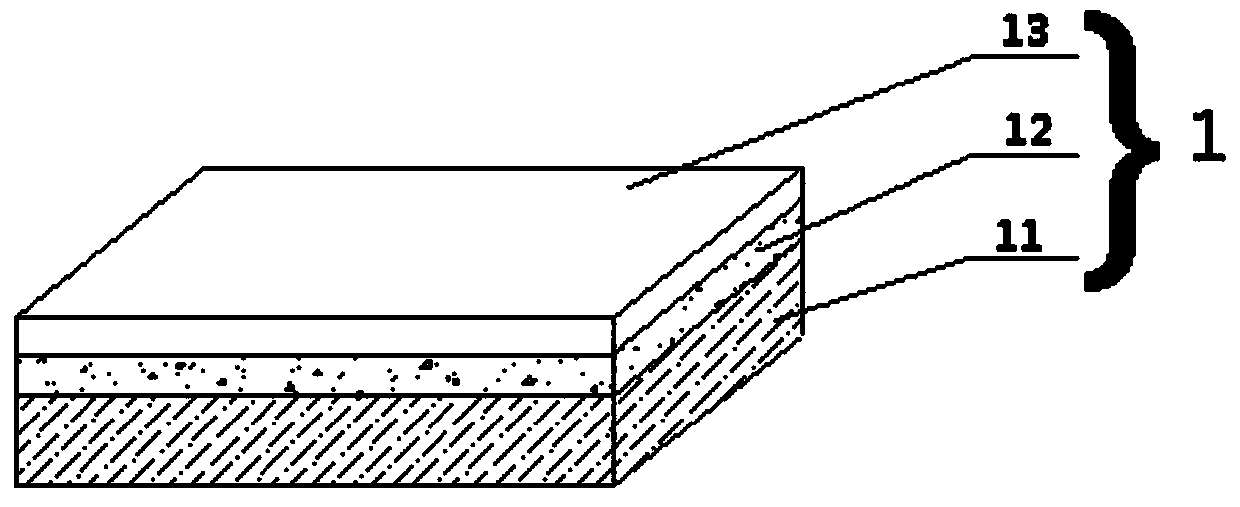

[0054] The wall is sequentially provided with a reinforcing layer, a color-changing coating and a waterproof layer;

[0055] Reinforcing ribs are installed inside the reinforcement layer, and the injection molding material of the reinforcement layer is a silicon-aluminum composite material.

[0056] Specifically, the number of the vertical fixing columns is 3, and the vertical fixing columns are equidistant and parallel to each other.

[0057] Specifically, the thickness ratio of the reinforcing layer, the color-changing coating and the waterproo...

Embodiment 2

[0070] An inner panel wall for building intelligent installation engineering, including a wall body, a vertical fixing column, a magnetic panel and a metal panel:

[0071] The vertical fixing column is installed in the groove at the top of the wall;

[0072] The magnetic plate is fixedly installed in the groove on the right side of the wall;

[0073] The metal plate is fixedly installed in the groove on the left side of the wall;

[0074] The wall is sequentially provided with a reinforcing layer, a color-changing coating and a waterproof layer;

[0075] Reinforcing ribs are installed inside the reinforcement layer, and the injection molding material of the reinforcement layer is a silicon-aluminum composite material.

[0076] Specifically, the number of the vertical fixing columns is 3, and the vertical fixing columns are equidistant and parallel to each other.

[0077] Specifically, the thickness ratio of the reinforcing layer, the color-changing coating and the waterproo...

Embodiment 3

[0090] An inner panel wall for building intelligent installation engineering, including a wall body, a vertical fixing column, a magnetic panel and a metal panel:

[0091] The vertical fixing column is installed in the groove at the top of the wall;

[0092] The magnetic plate is fixedly installed in the groove on the right side of the wall;

[0093] The metal plate is fixedly installed in the groove on the left side of the wall;

[0094] The wall is sequentially provided with a reinforcing layer, a color-changing coating and a waterproof layer;

[0095] Reinforcing ribs are installed inside the reinforcement layer, and the injection molding material of the reinforcement layer is a silicon-aluminum composite material.

[0096] Specifically, the number of the vertical fixing columns is 4, and the vertical fixing columns are equidistant and parallel to each other.

[0097] Specifically, the thickness ratio of the reinforcing layer, the color-changing coating and the waterproo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com