Triple-drive axle

A drive axle and transfer case technology, applied in the field of vehicle transmission, can solve the problems of complex cylindrical gear planetary transfer structure, uncompact structure, and influence on the light weight of the whole vehicle, so as to meet the requirements of light weight and passability, and the structure The effect of compact and convenient vehicle layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] In order to further set forth the technical scheme of the present invention and its working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

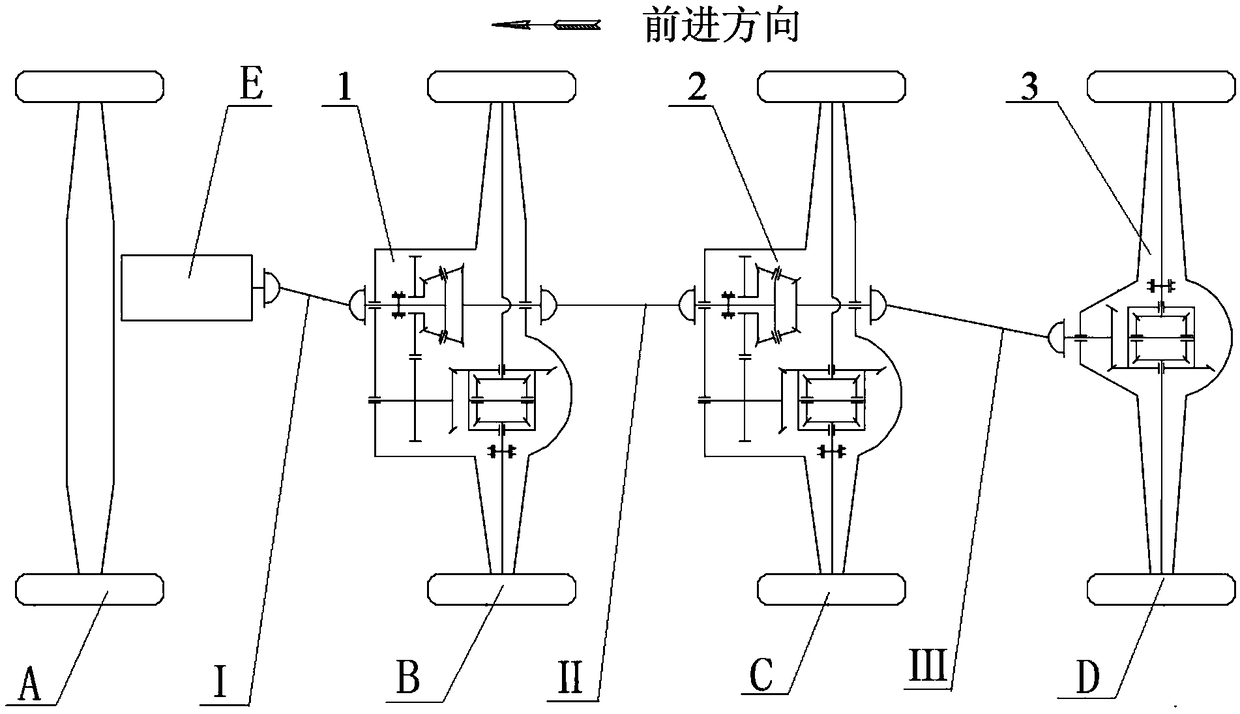

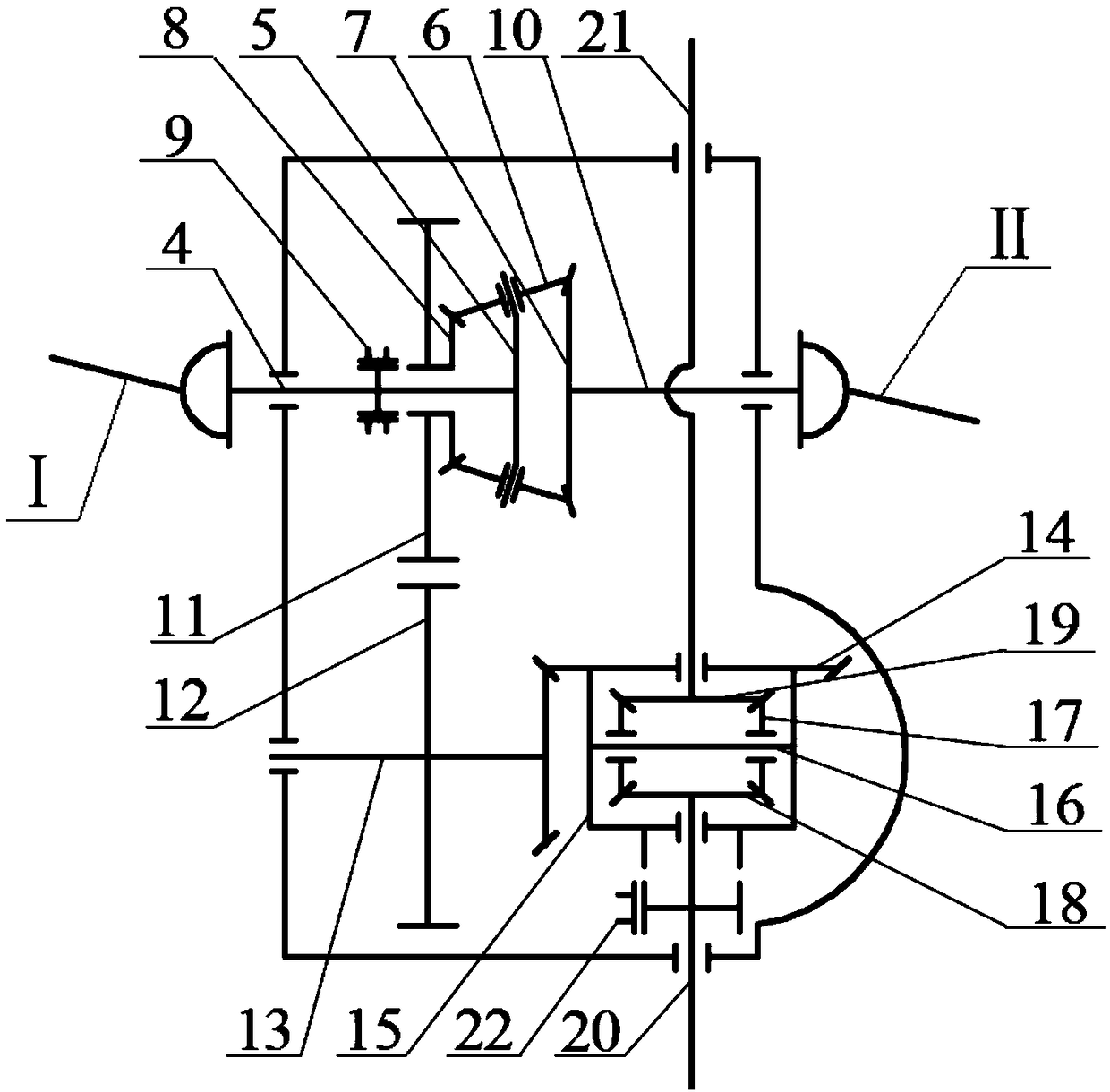

[0029] Such as figure 1 As shown, the present invention provides a kind of triple drive axle, mainly is made up of one bridge A, two bridges B, three bridges C and four bridges D, wherein, one bridge A is a non-drive bridge, two bridges B, three bridges C and The four axles D are drive axles, the gearbox of the vehicle is located on the rear side of the first axle A, the output end of the gearbox E is connected to the input end of the second axle B through the drive shaft I of the second axle, and the output end of the second axle B It is connected with the input end of the third bridge C through the transmission shaft II of the third bridge, and the output end of the third bridge C is connected with the input end of the fourth bridge D through the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com