Microweighing subpackaging machine and weighing subpackaging method thereof

A dispensing machine and trace technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of inoperability, large packaging errors, time-consuming and laborious, and achieve the effect of reducing electromagnetic wave interference, improving accuracy and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

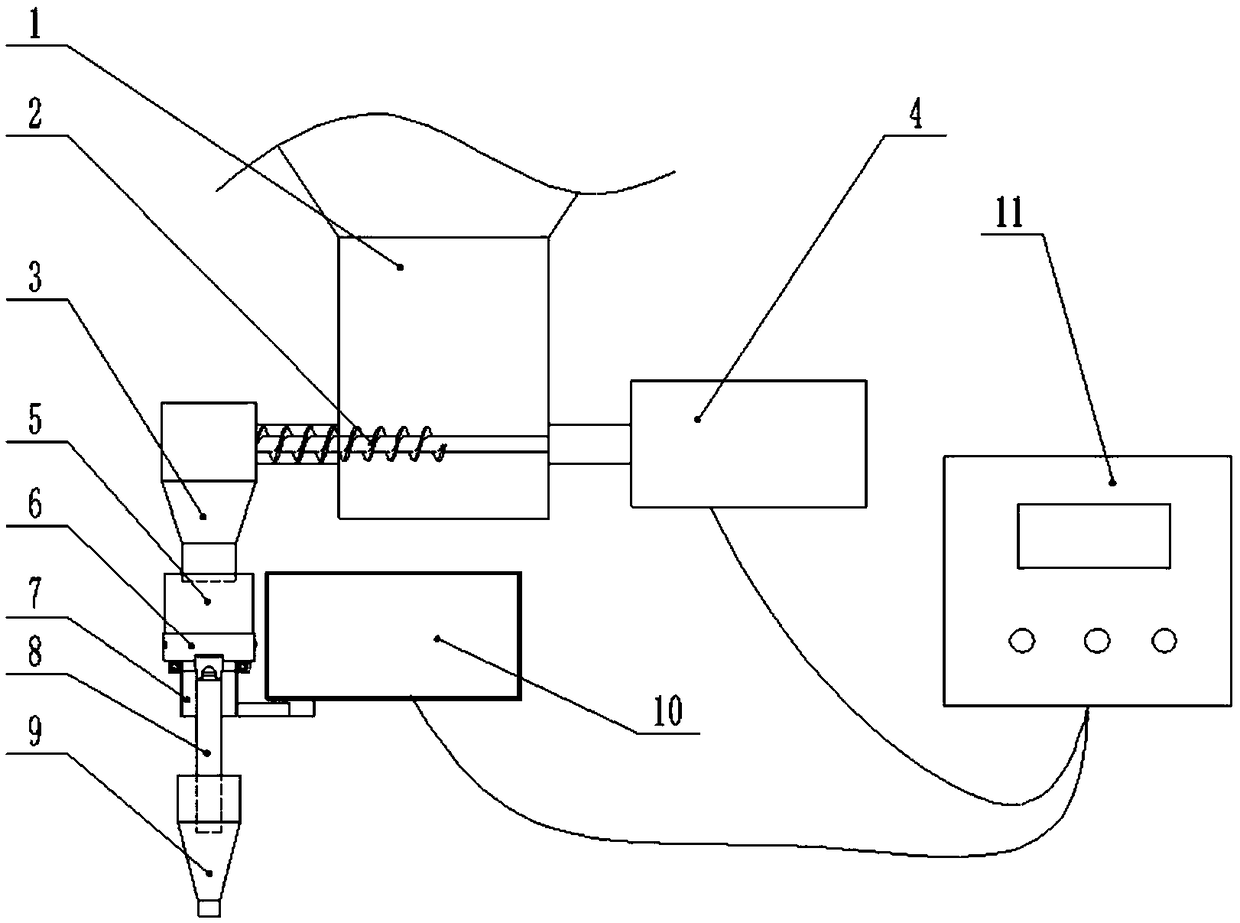

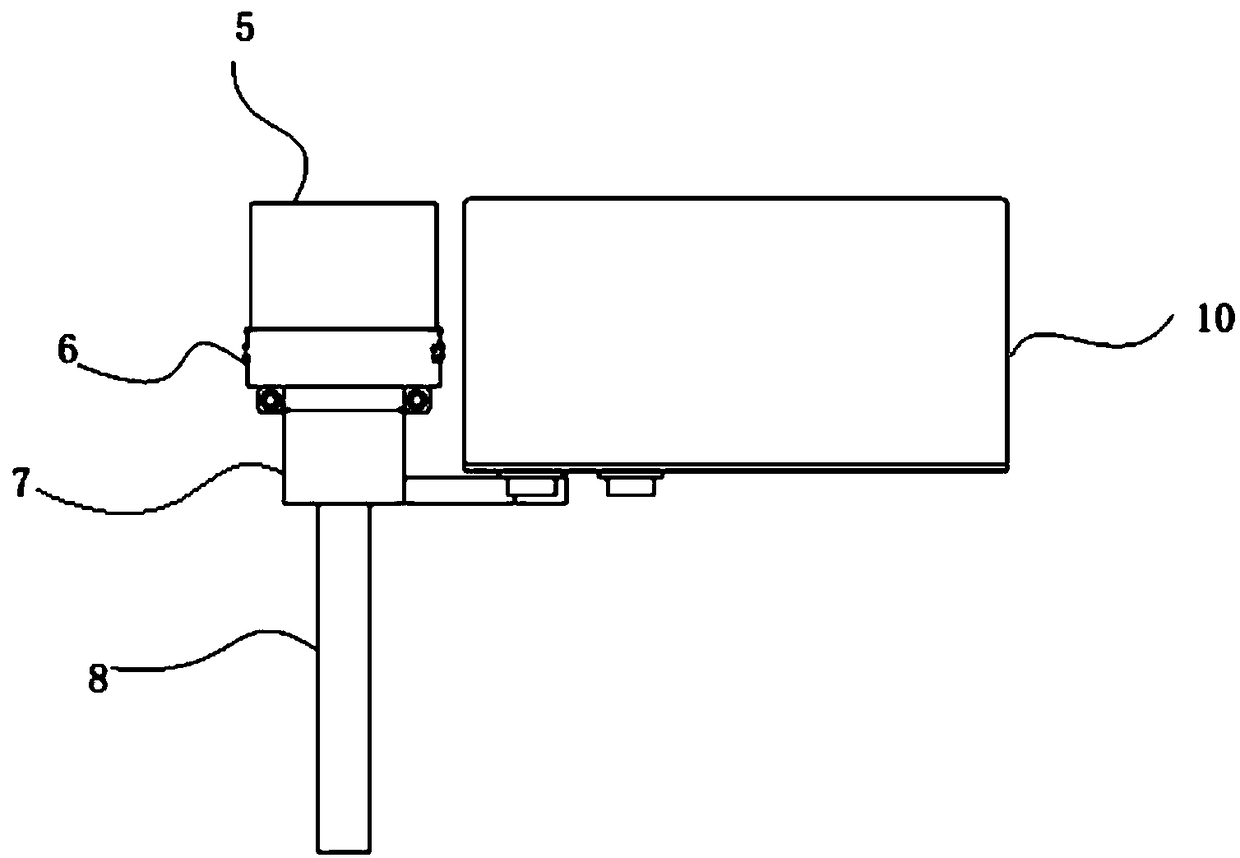

[0036] exist Figures 1 to 2 In the shown embodiment, the dispensing machine of the present invention includes a powder raw material bin 1, a screw feeder 2, a feeding dust collecting hopper 3, a motor 4, a weighing hopper 5, a micro disk feeder 6, and a stepping motor 7 , Unloading chute 8, packing receiving hopper 9, load cell 10, control system 11.

[0037] The powder raw material bin 1 is provided with a screw feeder 2 for conveying materials, one end of the screw feeder 2 is fixedly connected with the motor 4 arranged on the outer side of the powder raw material bin 1, and the other end of the screw feeder 2 It communicates with the feeding dust collection hopper 3 located on the other side outside the powder raw material bin 1, the lower end of the feeding dust collection hopper 3 communicates with but not connected to the weighing hopper 5, and the weighing hopper 5 is connected to the load cell 10 Electrically connected, the lower end of the weighing hopper 5 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com