Novel thresher feeding flow control device

A technology of feeding flow rate and control device, which is applied in the direction of large containers, containers, packaging, etc., can solve the problem of difficulty in separating tobacco leaves evenly, large load deviation of primary and secondary leaf toppers, and failure to achieve the expected purpose of tobacco leaf threshing control. Effect and other issues, to achieve the effect of improving the effect of tearing leaves and improving the uniformity of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

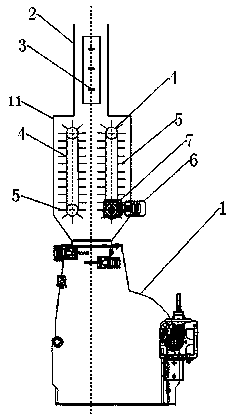

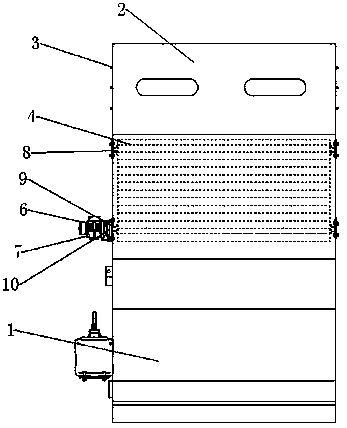

[0021] A novel defoliator 1 feed flow control device, such as Figure 1-3 As shown, it includes a feed pipe 2 located above the feed inlet of the leaf topper 1; it also includes a feeding device installed at the lower end of the feed pipe 2, and three are installed on the feed pipe 2 at intervals along the length direction of the feed pipe 2. . The photoelectric sensor 3 used for material level detection in the feed pipe 2; the blanking device includes a housing 11, two vertically parallel installations in the housing 11, and are respectively located on both sides of the feed pipe 2 for uniform material delivery Belt 4, and the motor 6 that drives and connects with two uniform material conveyer belts 4 through transmission mechanism; The belt surface of two uniform material conveyer belts 4 is provided with several uniform material partitions 5 at intervals; The homogeneous dividing plate 5 on the side is close to each other.

[0022] As a preferred technical solution, a cont...

Embodiment 2

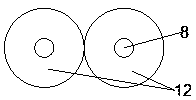

[0027] A new feeding flow control device for leaf topper 1, wherein another structural transmission mechanism is adopted, such as Figure 4 As shown, the upper rotating shafts 8 of the two uniform conveyor belts 4 are connected by a pulley mechanism 13, and two auxiliary wheels 14 are provided to realize the reverse rotation of the two uniform conveyor belts 4. All the other are basically the same as Example 1.

[0028] The invention can effectively monitor the flow state of the tobacco leaves in the feeder and compare it with the best state to adjust to the best value, so that the flow rate of each leaf topper on the production line can be in the best state. In this way, the uniformity of the beating load is greatly improved, the beating efficiency is improved, and unnecessary losses are reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com