A heat transfer structure for enhanced boiling

A technology of heat exchange structure and enhanced boiling, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low boiling heat transfer efficiency, small effective heat exchange area, and small number of vaporization cores, so as to delay dry burning. Crisis, the effect of increasing the number of vaporization cores, and increasing the effective heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A further detailed description is carried out below in conjunction with the description of the accompanying drawings:

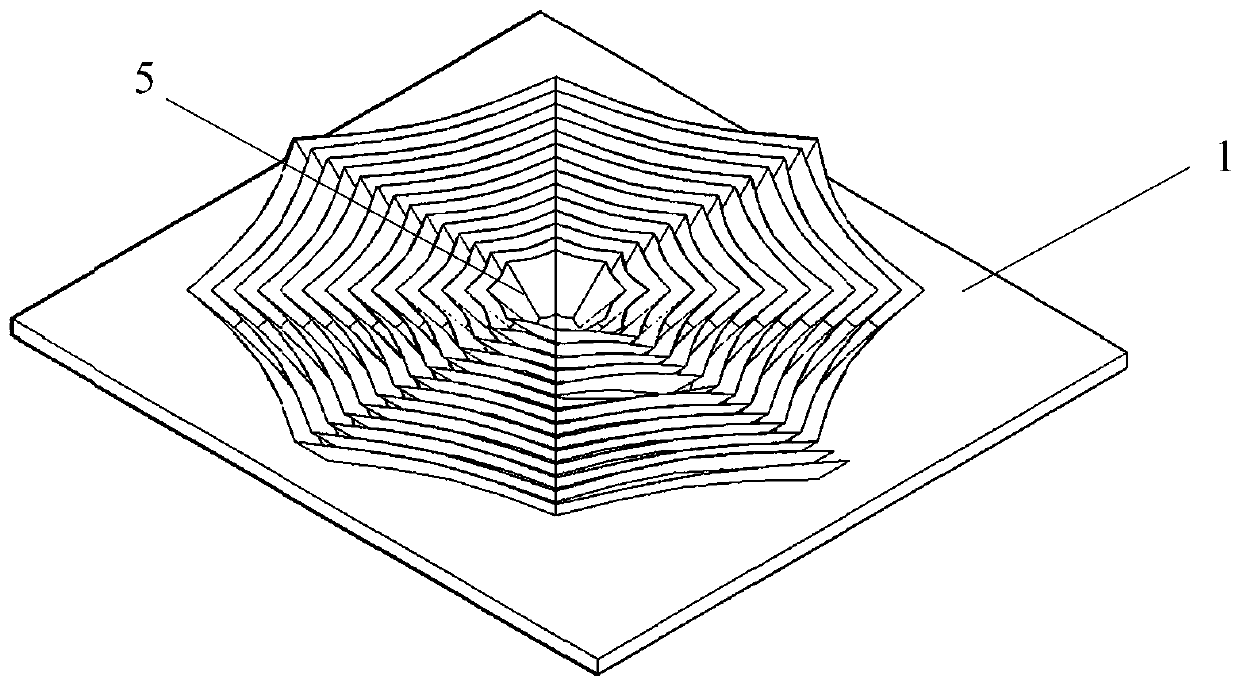

[0026] figure 1 Schematic diagram of the three-dimensional structure of the heat transfer surface structure for enhanced boiling. A heat exchange surface structure for enhanced boiling is composed of a helical heat exchange surface structure 1, and each heat exchange surface is distributed with hydrophilic regions 2 and hydrophobic regions 3.

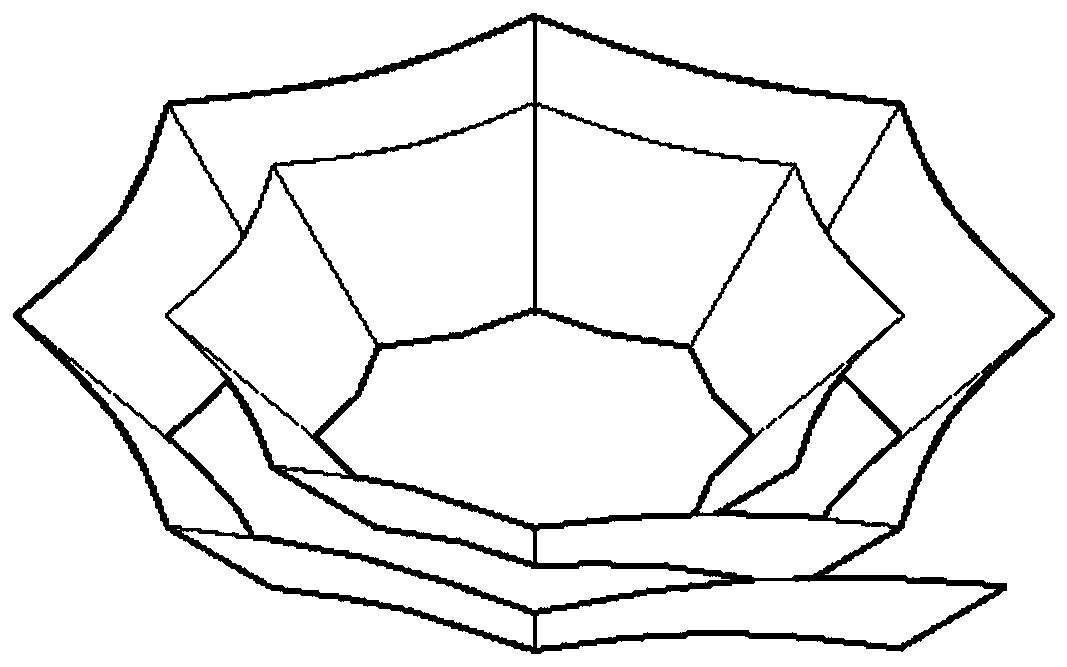

[0027] figure 2 Schematic diagram of a single-loop structure for a heat transfer surface structure that enhances boiling. The heat exchange surface is composed of a double-layer helical heat exchange surface structure. Each helical heat exchange surface structure is composed of eight surfaces, and the surfaces of different circles are equidistantly distributed. The first faces of a circle are connected to form a helical linear structure. There are grooves 5 formed between the surfaces due to processing.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com