led transverse fluid cooling cob light source and its encapsulation process

A fluid and lateral technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of shortened light source life, high heat dissipation efficiency, light decay, etc., and achieve the effect of high heat transfer performance and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

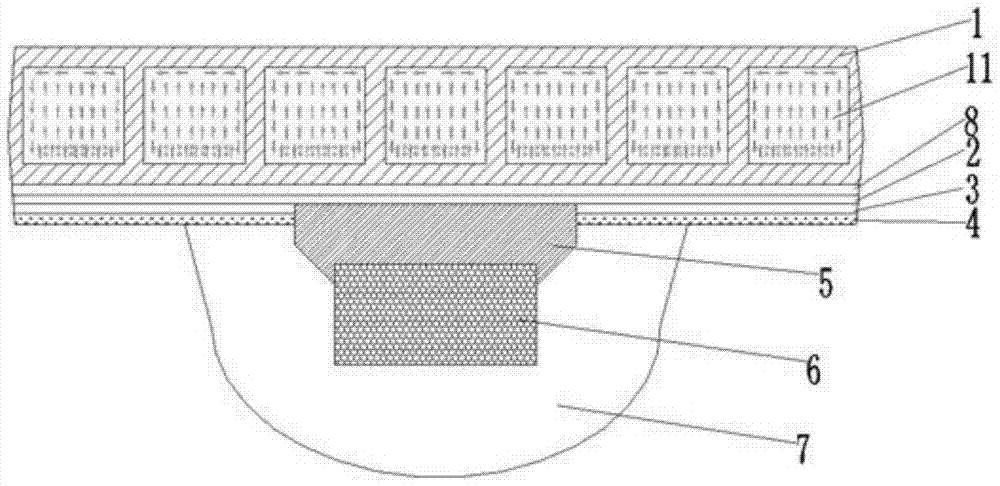

[0025] see figure 1 The LED lateral fluid cooling COB light source described in the embodiment of the present invention includes: a microarray heat pipe plate 1, a silver plating layer 2, a circuit layer 3, an insulating paint layer 4, a chip 6, a silica gel 7, and a copper plating layer 8. Array heat pipe plate 1, copper plating layer 8, silver plating layer 2, circuit layer 3, and insulating varnish layer 4 are compounded sequentially. The outer surface of the chip 6 is sealed and fixed with silica gel 7, and the chip 6 is closely attached to the silver plating layer 2 and welded. Fixed, the shape of the microarray heat pipe plate 1 is a thin plate. The microarray heat pipe plate 1 is integrally formed by cold drawing of aluminum material. Inside the microarray heat pipe plate 1, a plurality of independently operating micro-array channels 11 are arranged side by side. The micro-array channel 11 is filled with The working fluid is filled with working fluid in the micro-array ...

Embodiment 2

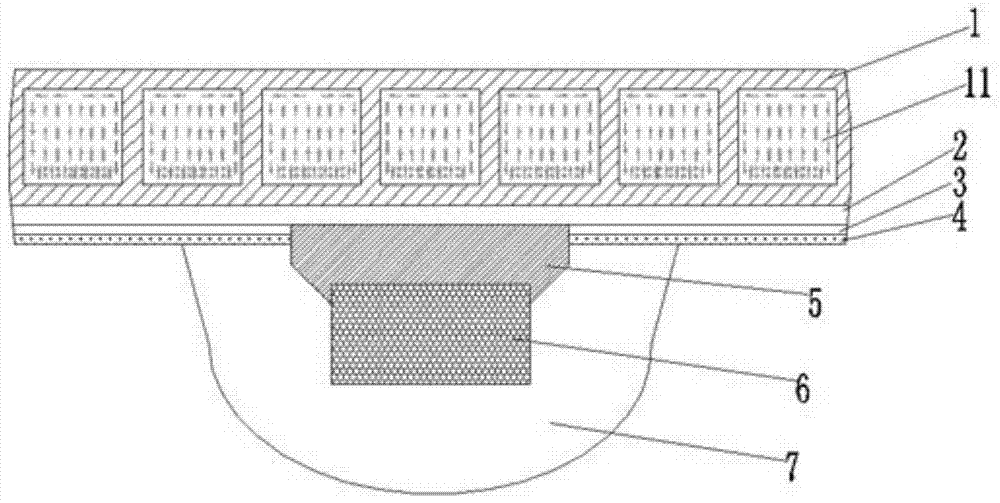

[0036] see figure 2 , the LED lateral fluid cooling COB light source described in the embodiment of the present invention includes: microarray heat pipe plate 1, silver plating layer 2, circuit layer 3, insulating paint layer 4, gold tin 5, chip 6, silica gel 7 and copper plating layer 8 , the microarray heat pipe plate 1, the copper-plated layer 8, the silver-plated layer 2, the circuit layer 3, and the insulating varnish layer 4 are sequentially compounded, and gold tin 5 is arranged between the chip 6 and the silver-plated layer 2, and the chip 6 and the silver-plated layer 2 are flip-chip connected with gold tin 5, and the outer surface of the chip 6 is sealed and fixed with silica gel 7. The shape of the microarray heat pipe plate 1 is a thin plate, and the microarray heat pipe plate 1 is integrally formed by cold drawing of aluminum In the microarray heat pipe plate 1, a plurality of independently operating microarray channels 11 are arranged side by side. The microarra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com