Multi-thermistor temperature sensor and power battery BMS device detecting system

A temperature sensor and thermistor technology, applied in the field of sensors, can solve problems such as the inability to distinguish the temperature of the battery, the safety of other people's lives, and the heating and burning of the battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

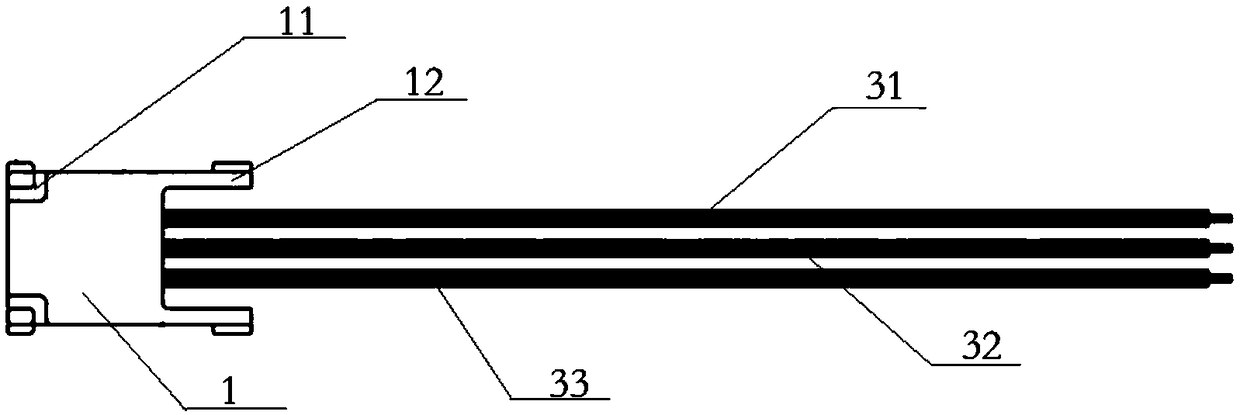

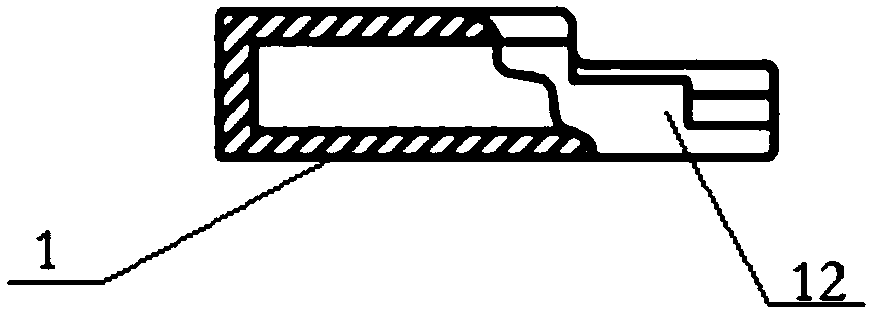

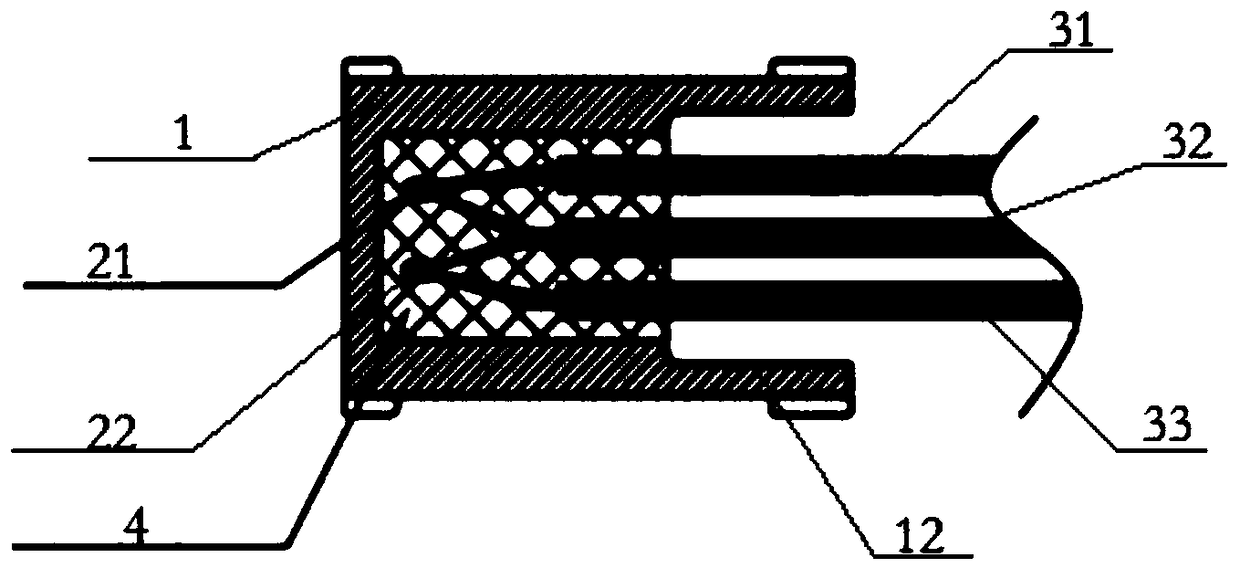

[0030] A temperature sensor with multiple thermistors, such as figure 1 As shown, it includes a shell 1, at least two thermistors and at least three wires, the pins of the thermistors are connected to each other to form a parallel relationship between the thermistors and the thermistors The pins are respectively connected to one end of the wires one by one, all the thermistors and the ends of the wires connected to the thermistors are wrapped in the casing, and the other ends of all the wires extend outside the casing, The shell is filled with epoxy resin 4 .

[0031] In this embodiment, more specifically, there are two thermistors, and the wires are three wires, and the two thermistors are respectively denoted as the first thermistor 21 and the second thermistor 22, and the three wires are respectively denoted as As the first wire 31, the second wire 32 and the third wire 33, the first pin of the first thermistor 21 is connected to the first wire 31, and the second pin of th...

Embodiment 2

[0035] A temperature sensor of multiple thermistors (not shown in the figure), including a shell, at least two thermistors and at least three wires, the pins of the thermistors are connected to each other to form a thermistor and the pins of the thermistor are respectively connected to one end of the wire in one-to-one correspondence, all thermistors and the ends of the wires connected to the thermistor are wrapped in the shell, all The other end of the wire extends outside the shell, and the shell is filled with epoxy resin.

[0036]When there are three thermistors, the wires are four wires, and the three thermistors are respectively denoted as the first thermistor, the second thermistor and the third thermistor, and the four wires are respectively denoted as the first thermistor. A wire, a second wire, a third wire and a fourth wire, the first pin of the first thermistor is connected to the first wire, and the second pin of the first thermistor is connected to the second the...

Embodiment 3

[0041] The power battery BMS device detection system based on the multi-thermistor temperature sensor of embodiment 1 and embodiment 2 is used to judge the temperature of the battery pack, including the above-mentioned multi-thermistor temperature sensor and battery BMS device, The wire of the temperature sensor is connected to the control system of the battery BMS device, the temperature sensor is connected to the battery pack for detecting the temperature signal of the battery pack, and the temperature sensor feeds back the temperature signal to the battery BMS device As the control system of the battery BMS device is equipped with a corresponding alarm prompt device, if one of the thermistors is abnormal, that is, there is a problem with the detection of one of the thermistors, then the temperature sensor will monitor the other thermistors. The temperature signal is fed back to the control system of the battery BMS device, and the corresponding alarm prompt device will issue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com