Method and device for detecting motor bearing failure

A technology for motor bearings and faults, which is applied in the direction of measuring devices, mechanical bearing testing, and testing of mechanical components, can solve problems such as difficult to accurately extract fault features, signal mode aliasing, nonlinearity, etc. Modal aliasing, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

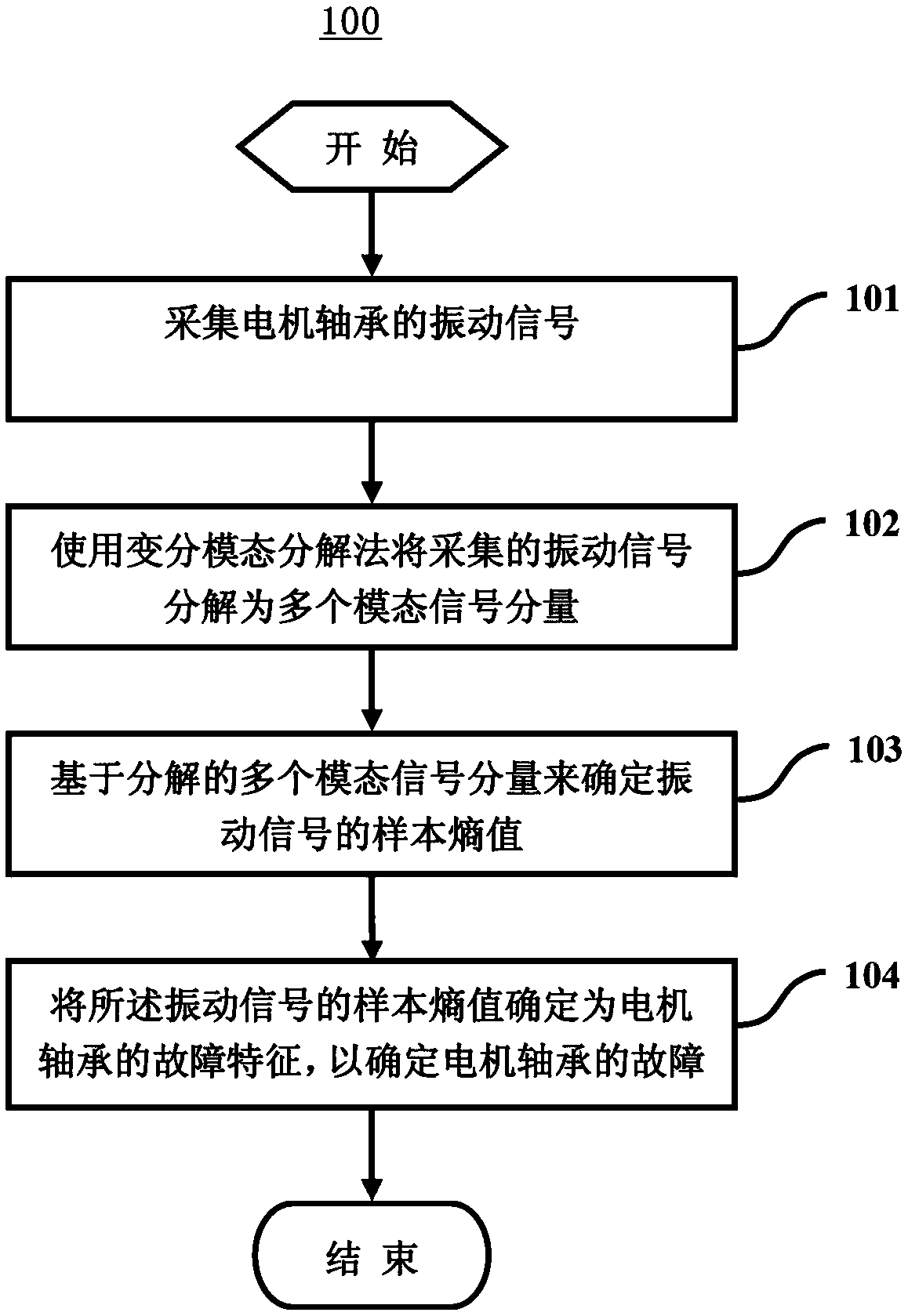

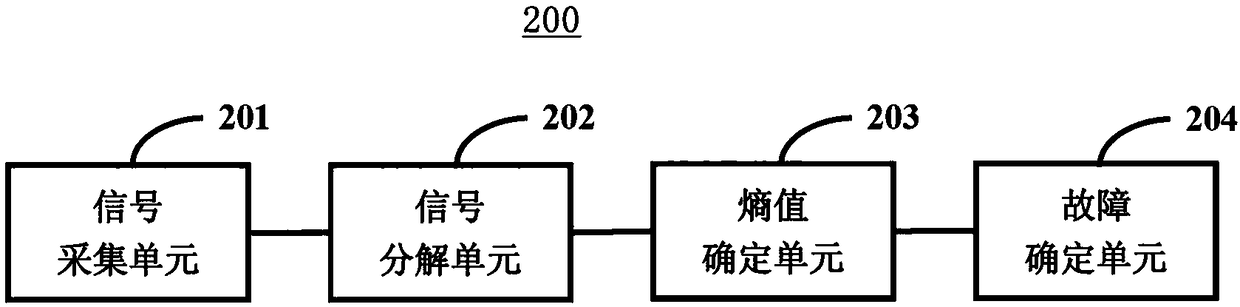

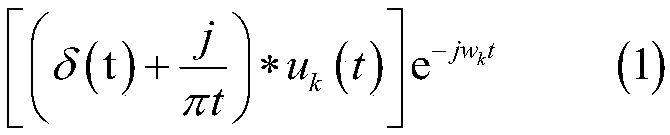

[0020] The idea of the present invention is: first, the original input signal from the motor bearing is decomposed by using the variational mode decomposition method (VMD), and then an effective modal signal component is selected from the decomposed multiple modal signal components to calculate the original input signal The sample entropy value of the signal is determined, and the sample entropy value of the vibration signal is determined as the fault feature of the motor bearing, so as to determine the fault type of the motor bearing. Since the signal components decomposed by VMD are nonlinear and non-stationary, the complexity of the original input signal is effectively reduced. In addition, the problem of modal aliasing in the decomposed signal is effectively solved and effectively avoided. The occurrence of the endpoint effect. In addition, since the sample entropy value of the decomposed signal is used as the fault feature of the motor bearing, the extracted features ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com