A kind of testing device and testing method for shear creep performance of brazed joint

A technology for brazing joints and testing devices, which is applied to measuring devices, uses a stable shear force to test the strength and strength properties of materials, etc. The effect of small test error, improved test accuracy and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention proposes a test device and test method for the shear creep performance of brazed joints. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

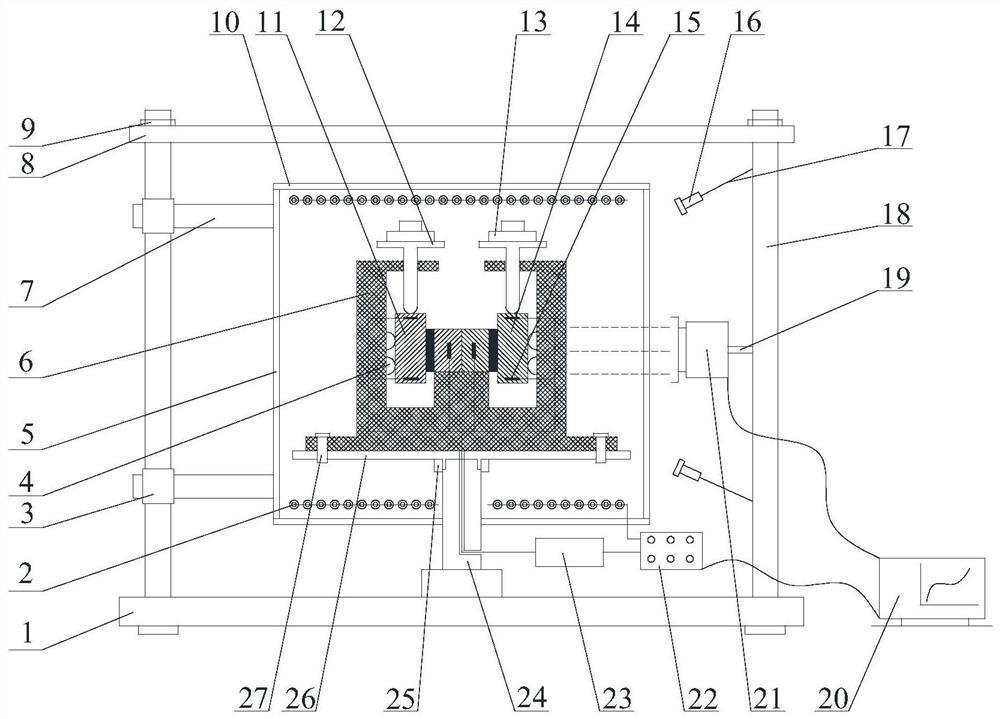

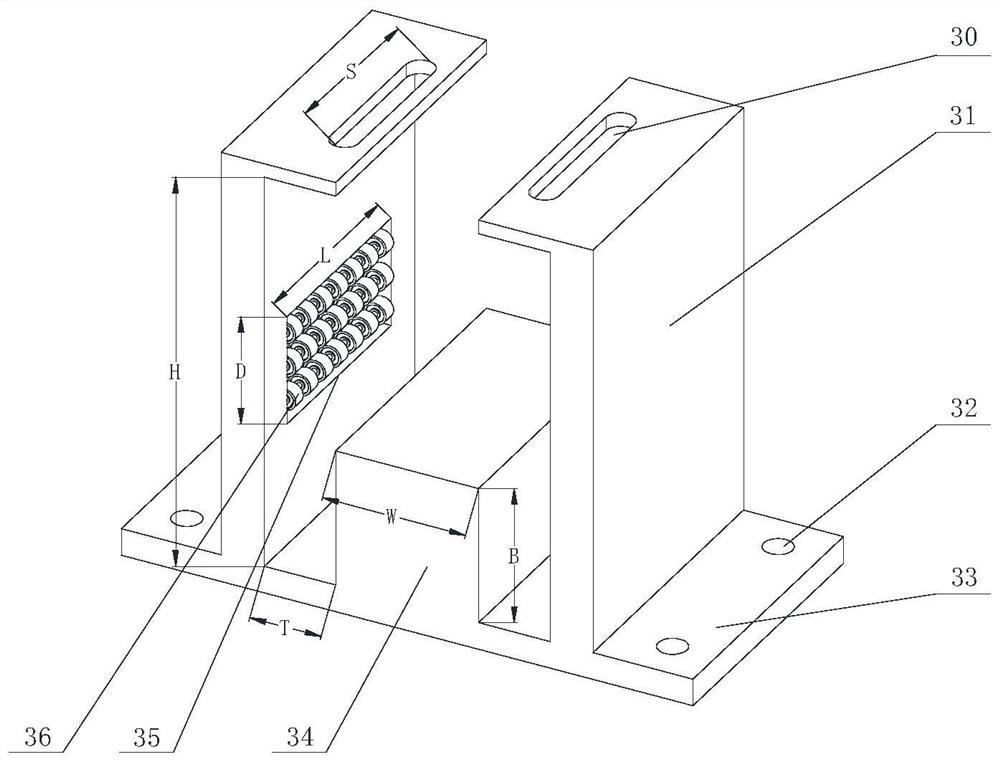

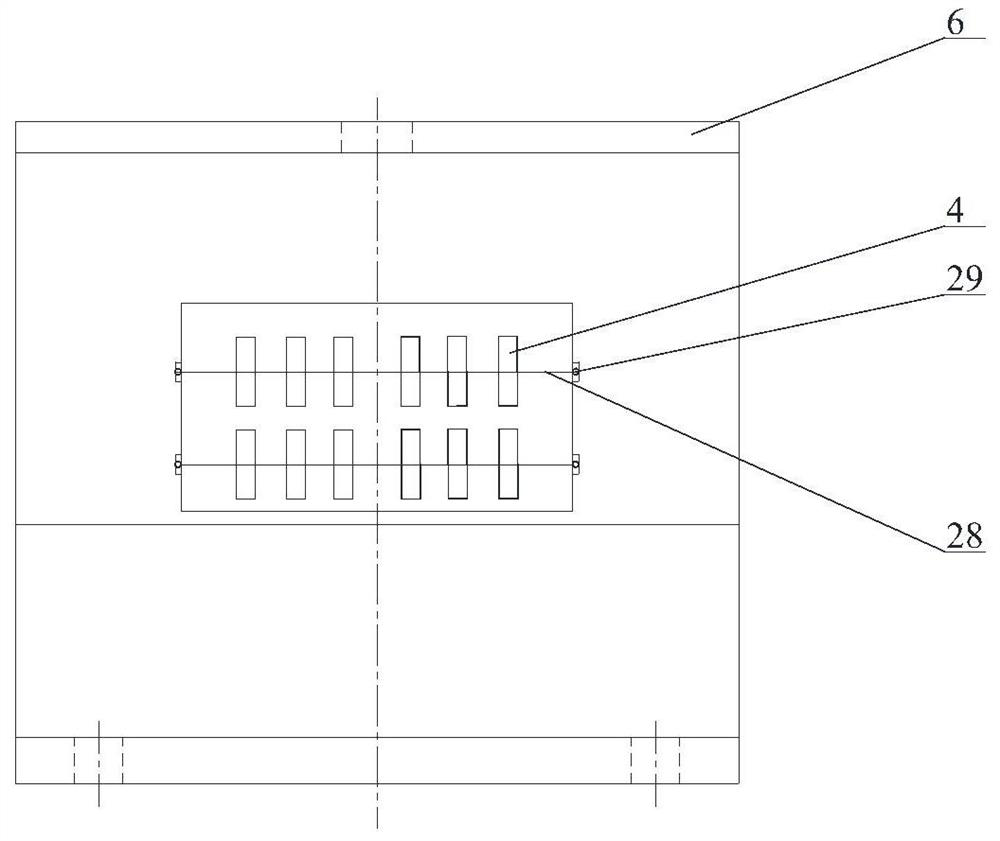

[0045] combine Figure 1 to Figure 5 As shown, the present invention is a brazed joint shear creep performance testing device, including a support mechanism, a heating mechanism, a loading mechanism, a control mechanism and a data acquisition mechanism, wherein the support mechanism includes a base 1, a heating furnace fixing ring 3, Shear fixture 6, heating furnace support bar 7, support frame fixing bar 8, support frame fixing nut 9, support frame 18, test bench 26; Base 1 is positioned at the bottom of this device, support frame 18 is installed on this base, 18. Preferably, the lower ends of two vertically arranged support rods are fixed together with the base. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com