3D laser scanning technology and BIM technology combined with the site construction management system

A laser scanning, on-site construction technology, applied in surveying and navigation, geometric CAD, image data processing, etc., can solve the problems of inability to fully control the site, inability to early warning and prevention, loss of timeliness and effectiveness of process monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

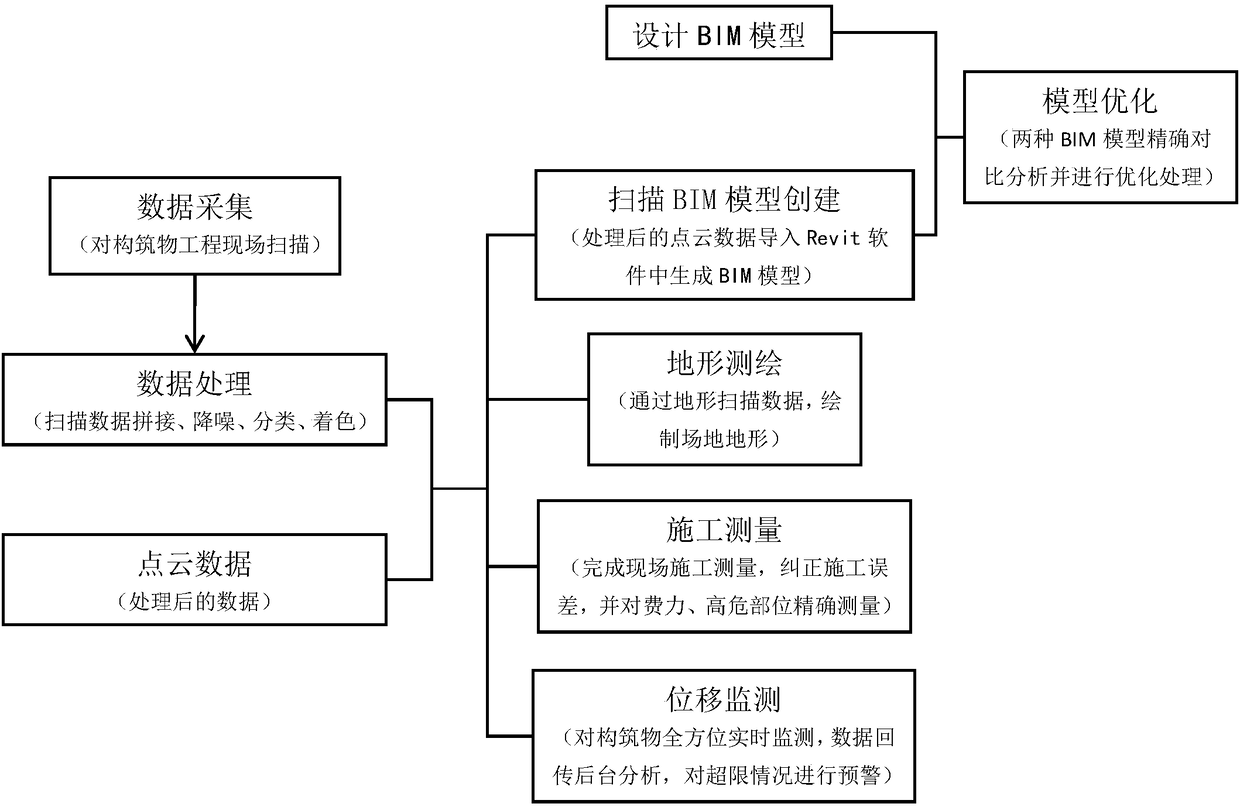

[0029] Such as figure 1 As shown, what the present invention discloses is a kind of on-site construction management combining 3D laser scanning technology and BIM technology, including the following steps:

[0030] The first step: data collection: use 3D laser scanner to scan on-site, collect the real and complete original data of the target structure project, and obtain point cloud data with accurate spatial information;

[0031] The second step: data processing: use the point cloud data preprocessing software to splicing, denoising, classifying and coloring the collected 3D laser point cloud data;

[0032] The third step: scan model establishment: import the preprocessed point cloud data into Revit software to generate a scan BIM model;

[0033] Step 4: 3D laser scanning and BIM technology synchronize on-site construction management:

[0034] (1) Perform accurate comparison and analysis of the scanned BIM model with the design CAD model and BIM model, find the differences ...

Embodiment 2

[0036] Such as figure 1 As shown, what the present invention discloses is a kind of on-site construction management combining 3D laser scanning technology and BIM technology, including the following steps:

[0037] The first step: data collection: use 3D laser scanner to scan on-site, collect the real and complete original data of the target structure project, and obtain point cloud data with accurate spatial information;

[0038] The second step: data processing: use the point cloud data preprocessing software to splicing, denoising, classifying and coloring the collected 3D laser point cloud data;

[0039] The third step: scan model establishment: import the preprocessed point cloud data into Revit software to generate a scan BIM model;

[0040] Step 4: 3D laser scanning and BIM technology synchronize on-site construction management:

[0041] (1) Perform accurate comparison and analysis of the scanned BIM model with the design CAD model and BIM model, find out the differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com