Testing device and method for determining minimum sprinkling flow density of spent fuel rod bundle

A test device and flow density technology, applied in the fields of nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve the problem of inability to obtain the temperature of spent fuel rods, and achieve the effect of preventing radioactive accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

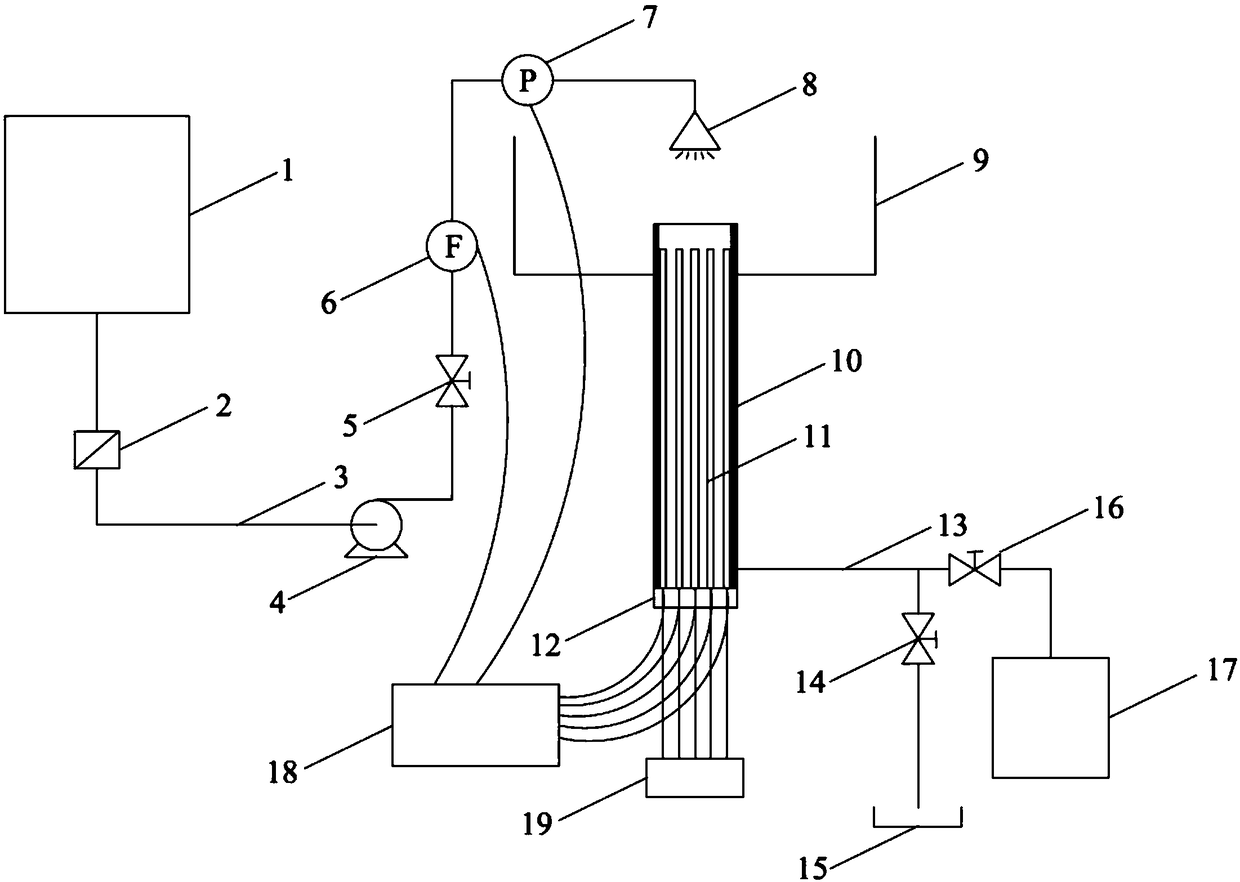

[0032] like figure 1 As shown, the test device for determining the minimum spray flow density of spent fuel bundles according to the present invention mainly includes:

[0033] A simulated spent fuel rod bundle 11 composed of 5×5 metal electric heating rods, heating wires are embedded in the metal rods, and the electric heating system 19 provides corresponding heating power for each metal rod to simulate different spent fuel rod decay heat power . Insulation 10 is arranged around the rod bundle, and a sealing structure 12 is arranged at the bottom to prevent the heat loss of the electric heating rod. The transparent enclosure 10 can also be used to prevent splashing of spray water and visual observation. The bottom of the enclos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com