Crushing device for processing kitchen wastes

A crushing device, a technology of kitchen waste, applied in grain processing, etc., can solve problems affecting urban appearance and living environment, and affecting people's health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

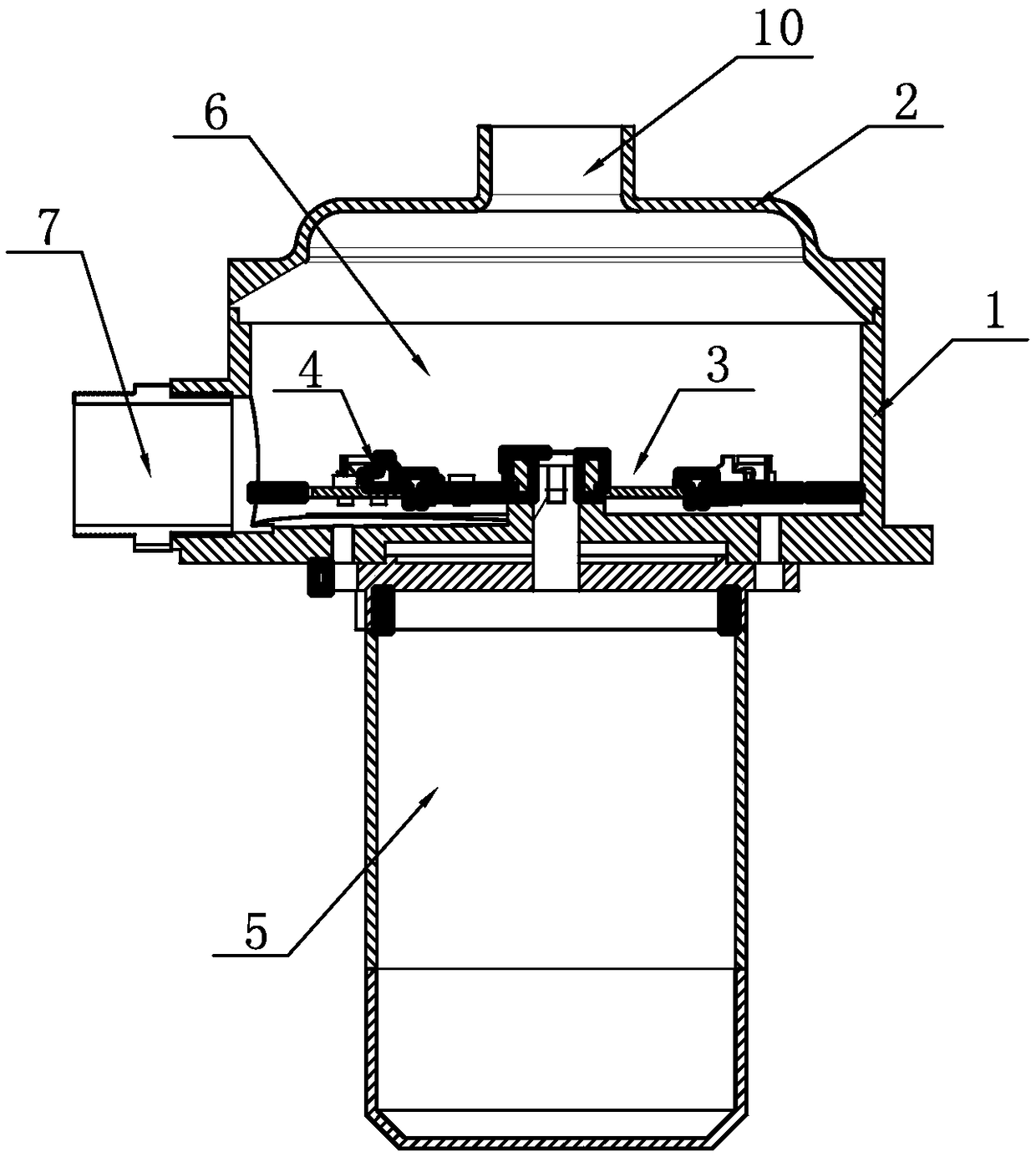

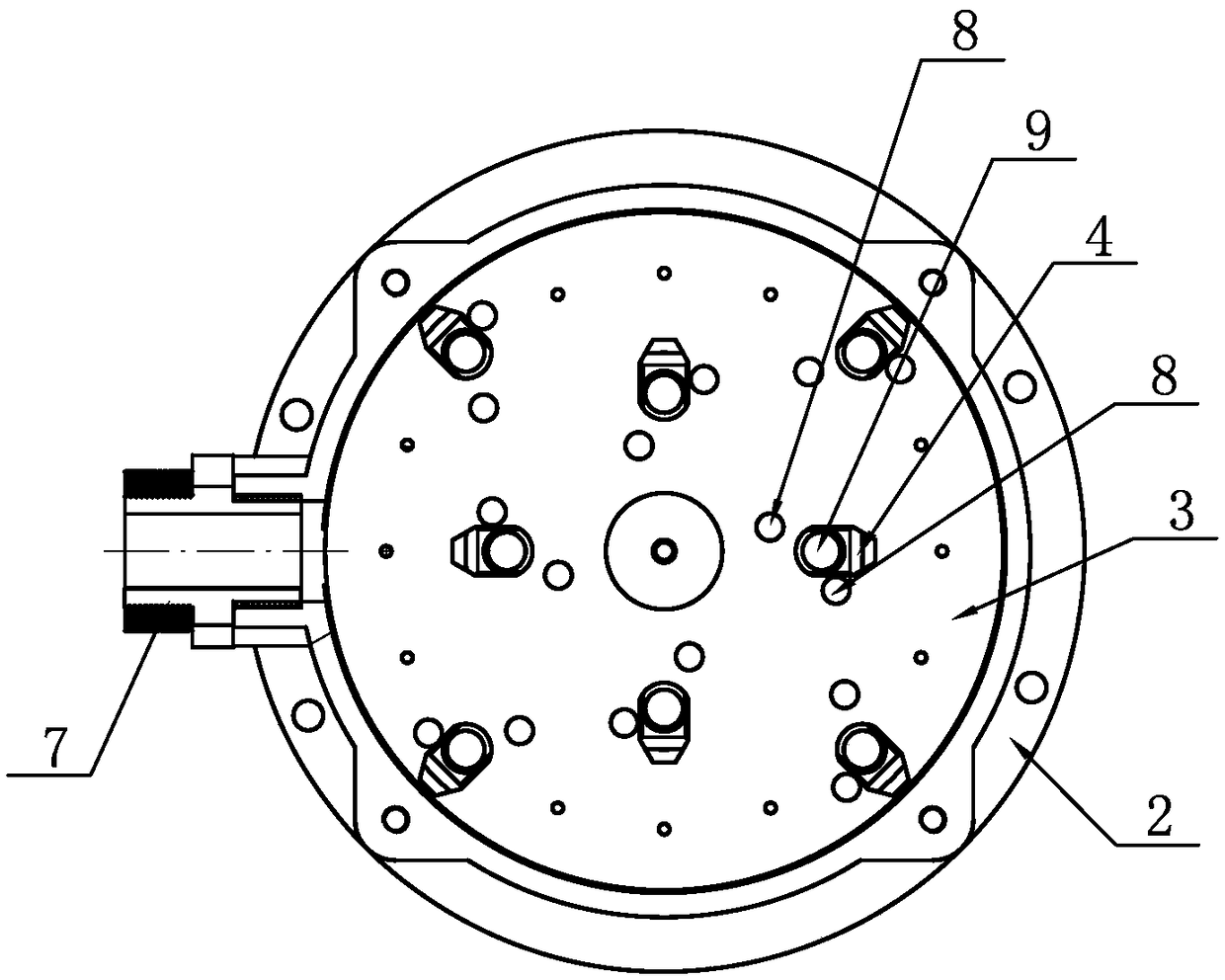

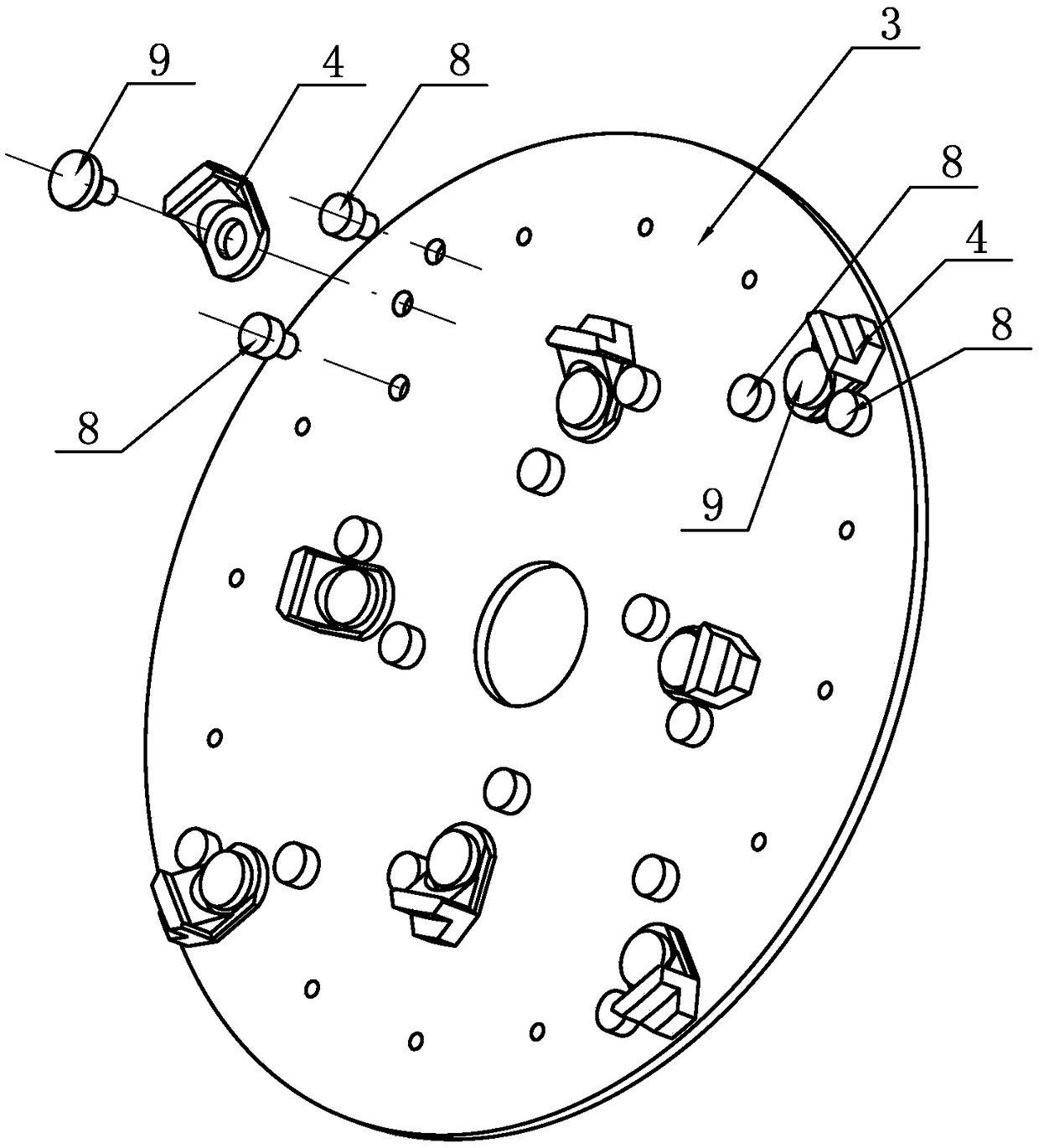

[0016] Embodiment 1: A kind of crushing device for processing kitchen waste, such as Figure 1-Figure 3 As shown, it includes a crushing chamber 1, a feeding cover 2, an end face cutter head 3, an end face throwing knife 4, a crushing motor 5, a material storage chamber 6, and a discharge port 7. The crushing motor 5 is fixedly installed on the side of the crushing chamber 1. At the lower end, the end face cutter head 3 is fixedly installed on the crushing motor 5, the end face throwing knives 4 are installed on the upper end surface of the end face cutter head 3 at intervals, and the feed cover 2 provided with the feed port 10 is fixedly installed on the crushing chamber 1 The upper end of the upper end forms a storage chamber 6 between the feeding cover 2 and the crushing chamber 1, the end face cutter head 3 is located in the storage chamber 6, the discharge port 7 communicates with the storage chamber 6, and the end face flail knife 4 passes through the rivet 9 is rotatabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com